Condition Monitoring Sensor With Integrated Data Preprocessing

September 9, 2020

Unscheduled stops and faults in the production process can be avoided using our new multi-functional condition monitoring sensor. This intelligent sensor provides you with condition information which you can use for automating costintensive manual inspections. This condition data is also an essential component for implementing smart and flexible manufacturing – a key to IIoT.

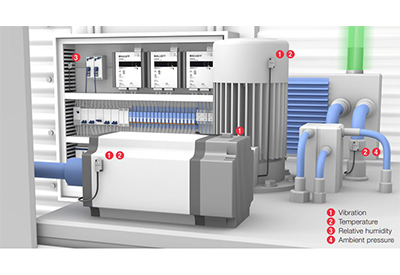

The Balluff condition monitoring sensor detects various physical variables such as vibration, temperature, relative humidity, and ambient pressure, processes them, and provides the desired data to a host system via IO-Link. In addition, the sensor can detect and communicate its condition, keeping you informed continuously of its temperature, number of operating hours, and start cycles.

The standardized IO-Link protocol means you can easily parameterize the sensor and match the processing in the sensor to your specific application. The process data structure permits five measured or preprocessed data types to be freely configured and cyclically transmitted. It is also possible to perform an acyclical request for additional statistical processing variables.

Additionally, you can use automated monitoring of measurement or processing variables to define limit values for pre- or main alarms. This generates warning messages, alerting you when problematic events occur.

The condition monitoring sensor from Balluff makes an essential contribution to the efficient and faultless operation of any equipment and significantly increases the efficiency of the overall system.

Features

■ Multiple measurements in one device: vibration, temperature, relative humidity, ambient pressure

■ Integrated processing circuitry with configurable data preprocessing

■ Configurable events and status indicators

■ Fast connection, and simple to incorporate using IO-Link

■ Compact form factor for restricted spaces

For more information, visit www.manuauto.com.