Comau Powers The Efficient Automation Production Of Next-Generation Electric Drive Systems For NIO

Comau Powers The Efficient Automation Production Of Next-Generation Electric Drive Systems For NIO

October 12, 2023

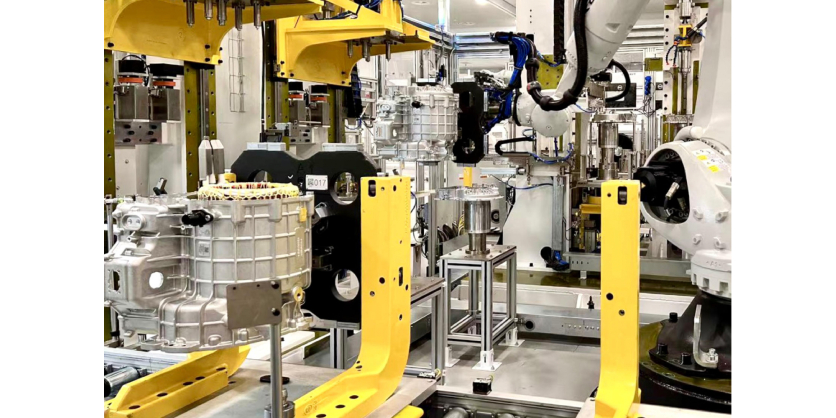

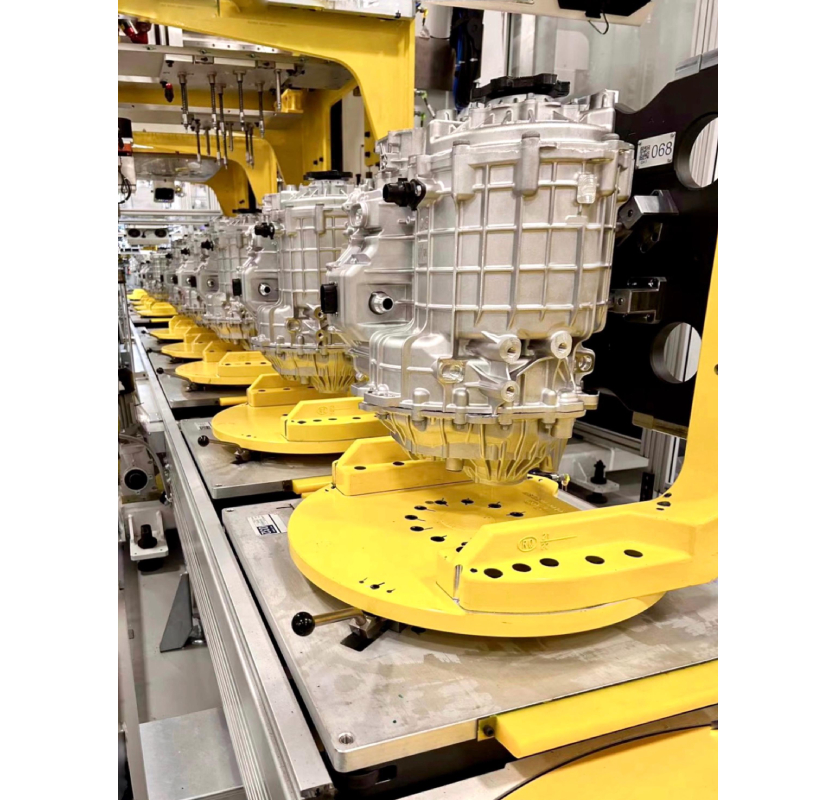

- Comau has designed and deployed a flexible automation solution to mass produce NIO’s next-generation electric drive systems

- The high-performance lines enable co-line production of the customer’s two electric drive systems and are expected to reach a full-scale capacity of 1 million units by the end of 2024

- The advanced manufacturing environment includes primary e-motor assembly lines, gearbox manufacturing lines and inverter assembly lines, as well as EOL (End of Line) testing processes

- Comau has also developed an ad-hoc adapter with a zero-point positioner that fully supports different assembly and ensures maximum flexibility for future NIO electric vehicles

Comau has implemented a high-performance turnkey solution to automate manufacturing of NIO’s next-generation electric drive systems. The multi-faceted project also ensures fast and reliable co-line production for the electric vehicle manufacturer’s third-gen induction and permanent magnet motors, both of which are integral parts of its proprietary electric drive systems (EDS). The comprehensive solution includes primary lines such as e-motor assembly lines, gearbox manufacturing and inverter assembly lines, as well as EOL (End of Line) testing processes. It is designed to support a large-scale annual production capacity of 1 million units, to be used within NIO’s electric sedans, coupes and SUVs, as well as select models of its sub-brand ALPS.

Comau’s advanced automation solution delivers optimal flexibility and scalability, allowing the customer to adjust its production environment to accommodate different process parameters as needed for new products. To further increase production line flexibility and enable co-line production of the two electric drive systems, Comau has collaboratively developed a new adapter with zero-point positioner together with NIO’s e-drive team. This innovative accessory effectively unifies design, process, and control standards, allowing different assembly requirements to be met while maintaining maximum flexibility.

Comau’s highly automated manufacturing environment also features 3D vision-guided robots, AGVs for autonomous material supply, and automatic tool-end loading, which have helped significantly enhance the customer’s production efficiency. Furthermore, the widespread use of quadnocular stereovision 3D cameras has allowed Comau to successfully overcome the limitations of vision guidance technology in terms of field of view and gripping range, granting automatic part positioning and assembly in addition to excellent repeatability.

“When it comes to implementing cutting-edge technological solutions, experience and know-how play a decisive role in success. We have been deeply impressed by Comau’s extensive expertise in electric drive systems assembly throughout our partnership. The innovative solution has reliably supported the project, helping us overcome various challenges and achieve our desired results,” said Alan Zeng, Senior Vice President of NIO and CEO of XPT. “Our collaboration follows a simultaneous engineering approach, which promotes close cooperation between both parties and drives project progress efficiently. This approach not only ensures progress and cost control but also guarantees the quality, performance and reliability of the final product.”

Alan Zeng, Senior Vice President of NIO and CEO of XPT

“Considering the rapid growth of new energy vehicles in China, a market in which production rates and sales volumes in the first half of 2023 have increased by 42.4% and 44.1% respectively1, the demand for electric drive systems has increased significantly,” explained Jeff Yuan, Comau Head of Countries Cluster APAC. “Our joint effort with NIO to create a highly automated production environment has allowed the customer to enhance efficiency, reduce costs, and improve the performance of its next-generation EDS technology.”

Jeff Yuan, Comau Head of Countries Cluster APAC

1Source: CAAM (China Association of Automotive Manufacturers)

Source

Related Story

Cooperation for the Multi-vendor Integration of Industrial Robots into the TIA Portal

Siemens presents the Simatic Robot Library for the Simatic Robot Integrator – a new universal robot library for the TIA (Totally Integrated Automation) Portal, which replaces the previous manufacturer-specific libraries. The specification has been developed in close cooperation with robot manufacturers ABB Robotics, Comau, Epson, FANUC, Kawasaki Robotics, KUKA, Panasonic Industry, STÄUBLI, Techman Robot, Yamaha, and YASKAWA. In future, users will be able to program most of the robots available on the market in the TIA Portal using the Simatic Robot Library, and make use of standard operating concepts based on the Simatic Robot Integrator and Simatic HMI.