Bihl+Wiedemann: Lenze Drives Are a Perfect Match for ASI-5

February 2, 2021

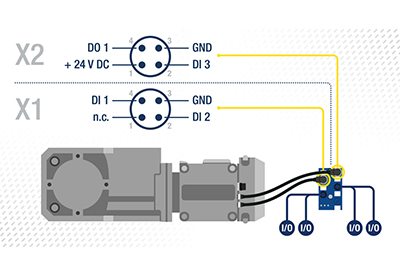

For many years, customers have enjoyed the benefits of AS-Interface for controlling Lenze Drives and frequency inverters. The free topology and cost-effective installation technology of ASi saves both time and money. Bihl+Wiedemann added to this perfect match with additional products like the ASi-5 self-configuring 8 I/O module (BWU4232). This module is ideal for the Lenze Smart Motor or other drives with binary control and four additional signals – either inputs or outputs.

This allows you to control two Lenze Smart motors with one 8 I/O module. The binary interface of the motor provides three digital inputs and one output – distributed over two M12 lines, which fits the module perfectly.

Flexible in use

Due to its flexibility, the ASi-5 self-configuring 8 I/O module works in other applications as well: For example, the IP20 version for a control station (pushbuttons and lights) in the control cabinet and the IP67 version for collecting sensors with either one or two switching signals per M12 socket.

High I/O density, precise diagnosis

Thanks to ASi-5, the 8-bit bidirectional process data are transmitted consistently in only 1.27 ms. Due to the high I/O density per ASi-5 module, the number of ASi addresses is greatly reduced. The channel-specific diagnosis in the module make it possible to detect a short circuit on the output or an overload of the sensor supply for each individual connection. Thanks to the cyclic diagnosis, errors can be quickly localized and eliminated. And in combination with our diagnostic software which provides you active assistance, troubleshooting becomes even easier.

All signals on a single line

In addition to controlling motors with AS-Interface you can transmit other standard or safety signals over the same network. This reduces the wiring effort and the associated costs.

ASi-5 self-configuring 8 I/O module in detail:

- – 8 digital inputs/outputs with ASi-5 in 1.27 ms

- – Self-configuring

- – Detailed channel-specific diagnosis

- – Individual feedback on the status of the outputs

- – Low overhead costs

- – High I/O density

- – Cost-effective digital outputs