Beckhoff Introduces Contact-free, Flying Motion Technology with XPlanar

October 28, 2020

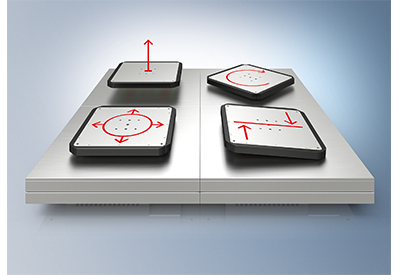

Beckhoff is unlocking entirely new possibilities in machine design with the introduction of XPlanar. In this innovative system for flying motion control, planar movers float freely above planar tiles arranged in customizable layouts and enable extremely flexible, precise and highly dynamic positioning. For machine builders and manufacturers, this results in maximum flexibility and simplification in machine and plant designs.

The XPlanar system combines the individual arrangement of planar tiles with multi-dimensional positioning capability of the planar movers floating above them. The movers enable jerk-free and contact-free motion in two dimensions at up to 4 m/s with 2 g acceleration and 50 μm positioning repeatability – completing movements without any noise or abrasion.

The planar motor system is highly scalable to suit individual machine and plant requirements. Due to the maximum flexibility in mover positioning and very high motion dynamics, it is possible, for example, to divide product flows very simply and individually, so that previously necessary robots or inflexible mechanical devices can be efficiently replaced. The contact-free mover travel also eliminates wear, emissions and carryover contamination from products being transported.

Breakthrough flexibility and versatility in motion control

The basis of the XPlanar system is the planar tiles, which measure 240 x 240 mm and can be arranged in any desired geometries that are precisely adapted to the application at hand. The tiles contain all power electronics and support Gigabit communication via EtherCAT G. A freely selectable number of planar movers float above them, made possible by integrated permanent magnets. The movers can be used not only horizontally, but also vertically and even upside down. There is a choice of four different planar mover types:

- – the 95 x 95 mm small mover for payloads up to 0.4 kg

- – the 155 x 155 mm standard mover for payloads up to 1.5 kg

- – the 155 x 275 mm long mover for payloads up to 3 kg

- – the 275 x 275 mm large mover for payloads up to 6 kg

The two-dimensional X/Y positioning of the movers is supplemented by additional motion functions:

- – lifting and lowering by up to 5 mm, including optional weighing functionality

- – tilting by up to 5° for transporting and handling liquids without spillage

- – rotation by up to ±15° or up to 360° above special planar tiles

The collision-free and synchronized movement of several movers with automatic path optimization are further features provided by TwinCAT 3 automation software from Beckhoff. Combining several movers together in a group, for example, makes it possible to increase the maximum payload.

Game-changer for the widest range of applications

XPlanar is optimal for use as a highly flexible transport system in general machine building, especially to automate packaging, assembly, sorting and order picking processes. A free choice of mover surfaces – easy-to-clean glass, stainless steel in hygienic design or plastic film – is ideal for use in a vacuum or clean room production environment. This makes XPlanar particularly well-suited to many industries, including food, pharmaceuticals and laboratory automation.

For more information, visit www.beckhoffautomation.com.