AIMS Connect: Your First Step to Integrated Manufacturing Provides Efficiency Gains of 20%, Increasing Productivity in Tool Production

November 1, 2024

ANCA’s innovative job management and production control software improves quality and reduces cost for tool manufacturers

ANCA CNC Machines, a world leader in CNC grinding technology, announces the launch of AIMS Connect, a job management and production control software designed to benefit tool manufacturing by optimizing processes, enhancing quality, and reducing costs.

In a highly competitive industry where efficiency is key, AIMS Connect addresses the growing demand for smarter, more streamlined operations. As a smart solution to integrated manufacturing, AIMS Connect has the potential to boost productivity by 20% or more, setting a new standard for excellence in the sector.

“AIMS Connect offers a flexible and customizable solution for tool manufacturers looking to increase efficiency, improve quality, and reduce costs,” said Steffen Kluth, ANCA Product Manager.

“Our goal is to make digital manufacturing accessible to everyone, and with AIMS Connect, we are helping our customers embark on a journey toward a fully integrated smart factory, step by step.”

Key features and benefits of AIMS Connect:

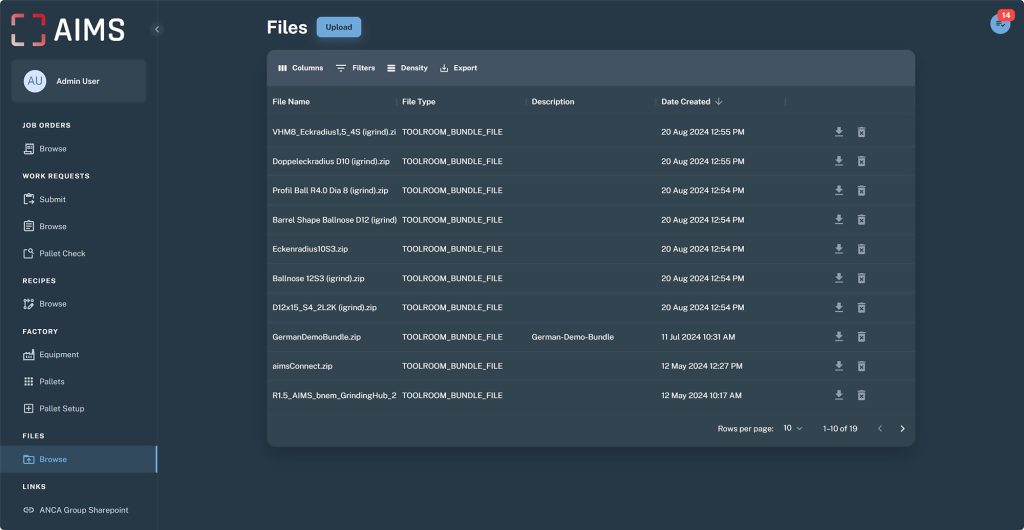

- Centralized machine file management: Offers a single source of truth for tool manufacturing data, reducing errors and inconsistencies.

- ERP/MES connectivity: Facilitates faster setup times and reduced manual data handling, improving overall operational efficiency.

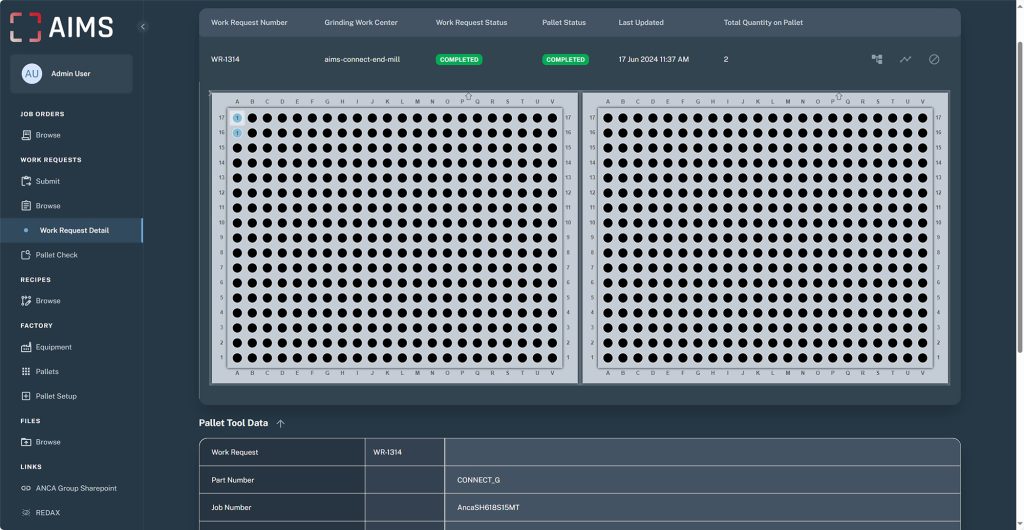

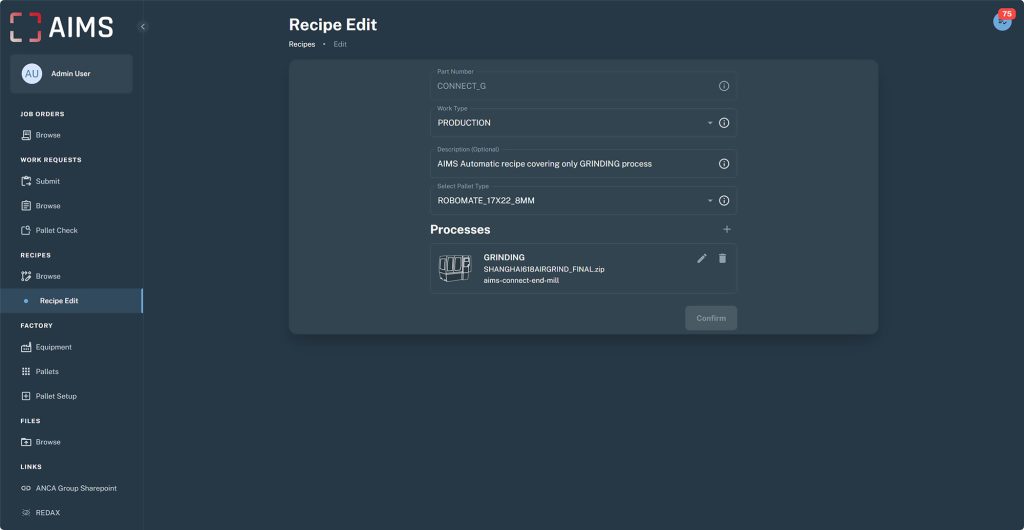

- Production control and optimization: Enhances tool quality and consistency across batches through robust process monitoring.

- Legacy machine integration: Enables seamless integration with existing equipment, minimizing disruption and reducing costs.

- Worker guidance system: Provides clear instructions and guidance, boosting workforce productivity and lowering training requirements.

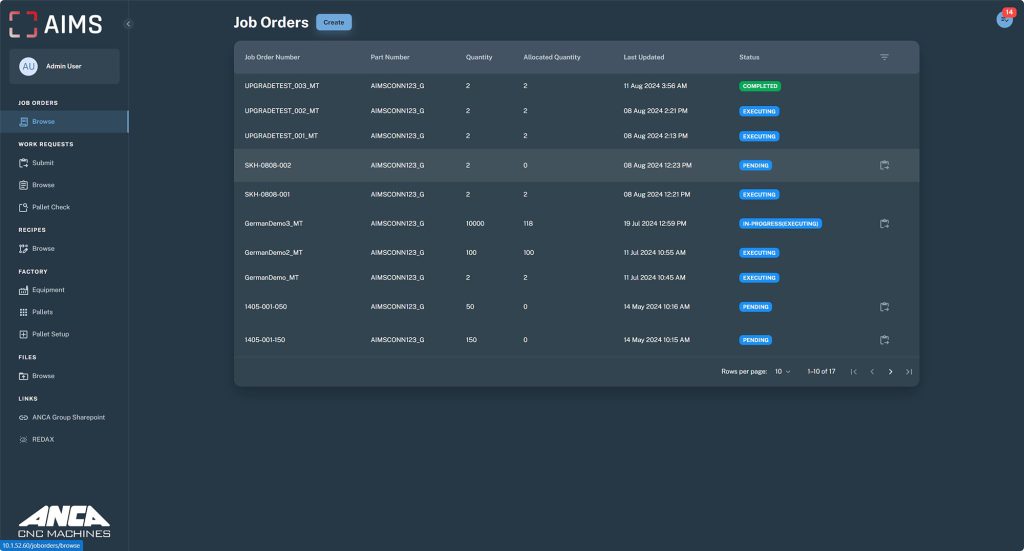

AIMS Connect is an accessible entry point into digital manufacturing, emphasizing the logical connection of machines and systems. It delivers transparent and verifiable processes, featuring a worker guidance system that informs employees about production stages and task schedules. This system frees skilled workers from repetitive tasks, allowing them to focus on areas where their expertise is most valuable. Each tool is meticulously described in a job order process, ensuring consistent quality through defined compensation strategies and logical frameworks.

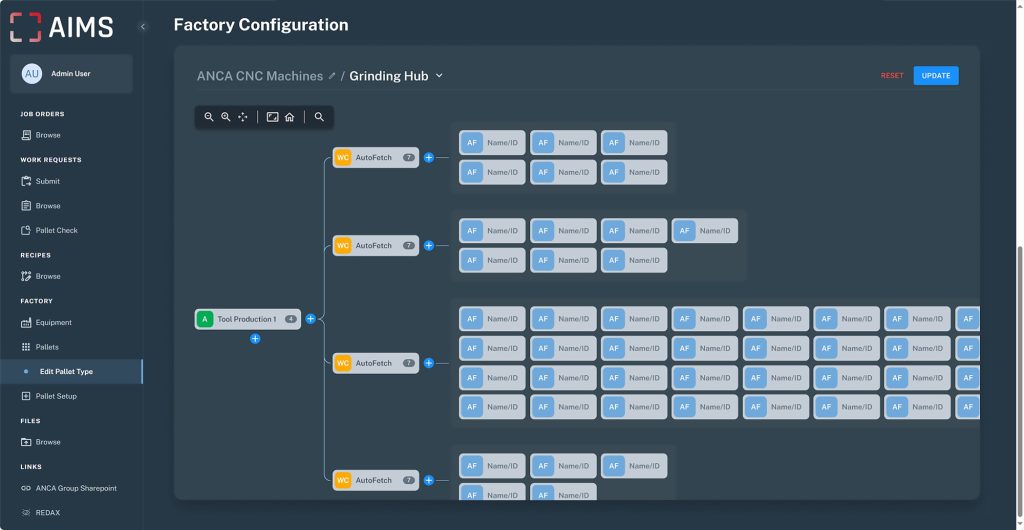

Building on the foundation laid by AIMS Connect, ANCA’s AIMS Automate transforms tool manufacturing into a fully integrated smart factory. AIMS Automate autonomously adapts to production changes, ensuring smooth operations even during disruptions. With the mobile robot, AutoFetch, it effortlessly manages tool pallet transfers, from raw materials to finished products, maximizing efficiency and minimizing downtime.

More Information

To learn more about AIMS Connect, visit www.anca.com/AIMS-Connect

Related Story

ANCA Marks Milestone Anniversary at IMTS with Debut of Next-Generation Technologies

ANCA at IMTS not only celebrated five decades of innovation but 35 years of successful operations in the USA and exhibiting the first machine ever bought in the U.S., a refurbished TG4, was a nostalgic nod to ANCA’s technological journey. Against ANCA’s latest solutions, this was a striking visual display of the company’s journey – from early innovation to being a future-ready leader in the tool and cutter grinding industry.