ABB’s New SDe Series to Boost Plant Reliability and Efficiency with Seamless Automation System Upgrade

April 24, 2024

- Offering innovation with continuity, ABB Ability™ Symphony® Plus SDe Series modernizes traditional process control system installations with minimal risk and disruption to plants

- Control system upgrades are key to futureproofing, securing and optimizing plant operations across industries

- Plant managers can plan for stepwise system upgrades reusing existing cabinets, field wiring, termination units and cabling

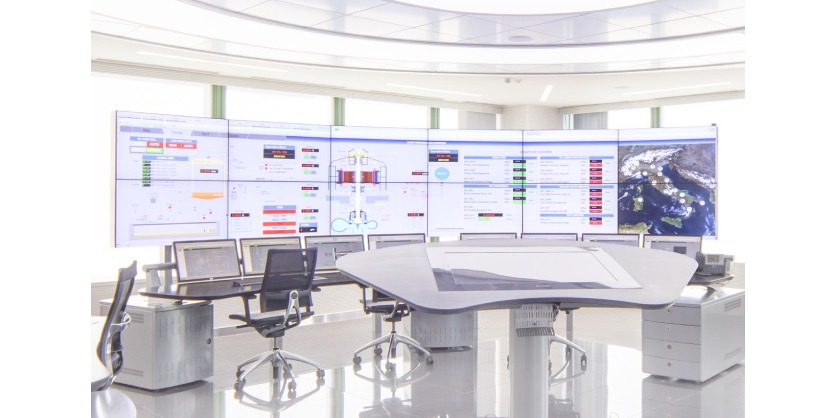

ABB has launched the ABB Ability™ Symphony Plus SDe Series, a portfolio of hardware products that help modernize existing process control system installations with minimal risk and disruption to plant operations. The new series enables plant operators in industries such as power, water, oil & gas, pharmaceuticals and pulp & paper to upgrade installed control systems to the latest technologies, driving efficiency and productivity improvements.

Offering innovation with continuity, the new SDe Series addresses one of the biggest challenges for control system owners: upgrading existing infrastructure without disrupting operations. SDe solutions enable stepwise evolution with minimal impact by preserving field wiring, termination units and module cabling, helping plant owners protect their Symphony Harmony and INFI 90 investments as process controllers, I/O modules and automation technology evolve.

“ABB’s modular approach to multi-year evolution facilitates strategic upgrades over a realistic, cost-effective timeframe, enhancing operational productivity and sustainability for plant managers,” said Stefan Basenach, Senior Vice President, Process Automation Technology, ABB. “With the new SDe Series, we are helping customers across industries ensure their plants continue to meet regulatory requirements while increasing efficiency and adapting to changing markets.”

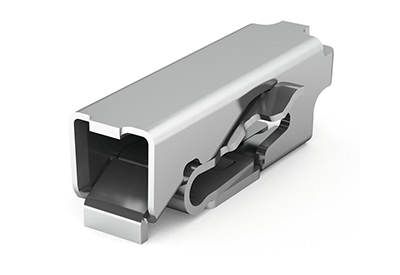

Providing seamless interconnections with smart field and electrical devices, as well as higher-level applications, the rugged control and I/O products of the SDe Series offer an extreme operating temperature range and a scalable architecture within a compact, modular footprint. Additionally, the series features sustainability improvements such as reduced power consumption and the use of standards-based technology that reduces plant owners’ total cost of ownership.

The key principles behind the SDe Series focus on evolving, enhancing and expanding ABB’s existing INFI 90, Harmony and Symphony DIN (SD) systems, which are currently installed in over 7,000 sites around the world. For Harmony Rack installations, the SDe series offers increased modularity, enhanced functionality, 1-to-1 module replacements and space-fit mounting options to ensure seamless evolution. Full compatibility with the SD series enables the expansion of SD systems using the latest technology and I/O hardware and software, delivering higher performance, reliability and capacity.

ABB’s Process Automation business automates, electrifies, and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water, and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered, and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

More Information

Related Story

Introducing Symphony® Plus: ABB’s Latest Distributed Control System Release Helps Accelerate Digital Transformation in Process Automation

ABB has launched its latest release of ABB Ability™ Symphony® Plus distributed control system (DCS) to further support digital transformation for power generation and water industries. With more than 40 years’ experience of total plant automation, the latest version of Symphony® Plus will further support customers’ digital journey through a simplified and secure OPC UA1 connection to the Edge and Cloud, without interfering with core control and automation functionalities.