ABB’s New Ty-Rap® TyGenic™ Antimicrobial Detectable Cable Ties Help Cut Contamination Risk

July 7, 2022

- •ABB’s new Ty-Rap® TyGenic™ cable ties are the industry’s first two-piece cable tie that is both antimicrobial* and detectable

- •Over 99 percent effective against a broad spectrum of microorganisms and detectable by x-ray, visual and metal detection systems

- •Helps protect against costly contamination and waste in food and beverage and pharmaceutical processing, healthcare, and hygiene-critical locations

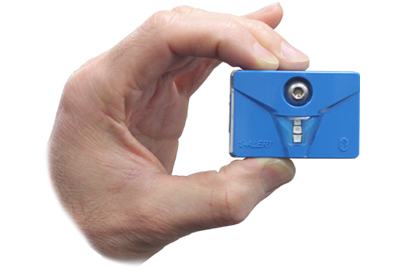

The cost of contamination can add up, averaging between $10-30 million in direct costs of a recall, plus lost sales, customer confidence and more. In facilities where bacteria reduction and detectability are critical, a standard cable tie may go unidentified in product and its notched design can be a home for microorganisms. To help reduce risk in contamination-sensitive environments such as food and beverage processing, healthcare and pharmaceuticals, ABB has expanded its line of Ty-Rap® cable ties with Ty-Rap® TyGenic™ cable ties, the industry’s first two-piece antimicrobial* and detectable cable tie.

ABB’s Ty-Rap® cable ties safely secure everything from electrical cords and equipment to hoses, wires and more. Tested to be over 99 percent effective at inhibiting microbial growth, ABB’s Ty-Rap TyGenic antimicrobial detectable cable ties help protect against many types of microorganisms such as bacteria, viruses, protozoans and fungi like mold and mildew. Molded from an FDA and EU food contact-approved, halogen-free nylon resin blend, Ty-Rap TyGenic cable ties complement cleaning protocols and resist microbes from adhering and replicating on its surface.

To further combat contamination, Ty-Rap TyGenic cable ties combine antimicrobial properties with detectable particles and a deep blue color for easy three-way identification via x-ray, metal and visual detection systems. Made from UV-resistant material and designed for operating environments up to 85 °C (185 °F), ABB’s new Ty-Rap TyGenic cable ties have the Grip of Steel™ stainless steel locking device for proven fastening performance in commercial and household use.

“No one wants to worry about fragments in their product and risk costly contamination. Our Ty-Rap TyGenic cable ties combine antimicrobial technology with detectability and fastening performance to help customers create cleaner, safer environments,” said Matthias Heilmann, President, ABB Installation Products Division. “Expanding our Ty-Rap line enables us to continue to deliver the right solution for the application and products that go where others cannot, from production plants to other planets.”

Originally developed to bundle aircraft wiring, standard Ty-Rap cable ties were patented in 1958. Over 30 billion Ty-Rap cable ties have since been produced – enough to stretch to the Moon and back over a dozen times. ABB Installation Products offers more than 250 varieties of Ty-Rap cable ties available in multiple materials and proven in a wide range of temperatures and applications, from buildings, manufacturing and transportation to the deepest oceans and on the Mars Rover in outer space.

The latest innovation in ABB’s Ty-Rap product line, Ty-Rap TyGenic antimicrobial detectable cable ties are patent pending, available in four sizes and meet industry safety standards.

Produced at ABB’s Vega Baja, Puerto Rico, facility and available globally, information about Ty-Rap TyGenic cable ties can be found at electrification.us.abb.com

*Note: Ty-Rap® TyGenic™ antimicrobial detectable cable ties provide no antimicrobial inhibitory activity beyond protection of the cable ties themselves.