ABB Robotics Introduces AppStudio No-Code Tool for Robot Interface Programming

January 29, 2025

ABB Robotics Introduces AppStudio No-Code Tool for Robot Interface Programming

- Unique software tool features drag and drop functionality for easy creation of customized operator interfaces for ABB robots and cobots

- Intuitive functionality and collaborative cloud-based library for application templates reduce set-up times by up to 80 percent

- No-code programming lowers the barriers to automation for beginners and experts

ABB Robotics has launched AppStudioTM, an intuitive no-code software tool designed to empower users of all experience levels to quickly and easily create customized robotic user interfaces. With intuitive functionality and features including a collaborative cloud-based library enabling users to share application templates, AppStudio will reduce setup times by up to 80 percent.

“A growing shortage of skilled labor requires the further simplification of automation and programming,especially among small and medium size Enterprises (SME) where complexity is seen as a major barrier to implementing robotic automation,” said Marc Segura, President ABB Robotics Division. “Designed for novices and experts alike, AppStudio is an exciting addition to ABB’s current software offering. By making it easier to create robot interfaces, it will save users significant time on setup and allow for fast and seamless robot integration across diverse applications.”

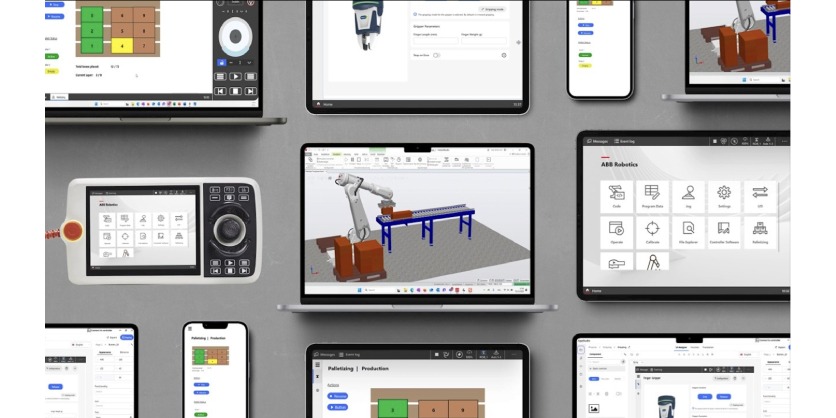

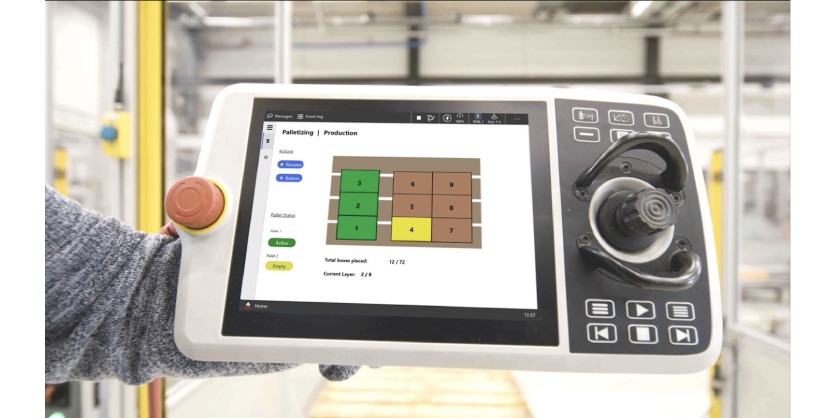

Compatible with all ABB robots on the OmniCoreTM controller platform, AppStudio offers unprecedented flexibility and ease for creating customized robotic user interfaces. After installing the software, users can repurpose a previously used setup or select from a cloud-based library of templates, models, modules, and examples enabling them to select options in twenty languages. Alternatively, customized interfaces can be created to fit any device and application, including the OmniCore FlexPendant, tablets, and mobile phones.

AppStudio also supports customers migrating from the IRC5 controller to the OmniCore platform, significantly reducing the time needed to rebuild interfaces from days to minutes. This feature ensures a smooth transition to the latest technology, enhancing efficiency and productivity.

With intuitive drag-and-drop functionality, AppStudio offers simplified configuration where users can add icons, dropdown menus, buttons, and other functions to tailor the interface to their specific needs. It also supports more advanced users, who can build custom interface elements using a JavaScript-based component kit, enabling a high degree of customization. Once developed, these elements can be shared with other users for streamlined project collaboration.

Once an interface has been created, it can be deployed to the ABB robot or a digital twin in ABB’s RobotStudio® programming tool. Through this connection, the robot can be programmed to carry out specific commands, such as performing an action or opening a gripper.

Together with ABB’s Wizard Easy Programming tool and RobotStudio, AppStudio makes the ABB robot portfolio one of the easiest to program, marking the start of a new chapter that will see robots being opened to a new audience of potential users.

AppStudio is available as a free download from ABB’s website.

ABBs comprehensive robotics platform is designed to support every stage of the engineering lifecycle, seamlessly integrating project conception, design, operation, and optimization. With a platform-driven approach and a common data model, ABB ensures that automation projects are efficient, accurate, and innovative.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and more than 105,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). global.abb

ABB Robotics & Discrete Automation as one of the world’s leading robotics and machine automation suppliers, is the only company with a comprehensive and integrated portfolio covering robots, Autonomous Mobile Robots and machine automation solutions, designed and orchestrated by our value-creating software. We help companies of all sizes and sectors – from automotive to electronics and logistics – to outperform by becoming more resilient, flexible and efficient. ABB Robotics & Discrete Automation supports customers in the transition towards the connected and collaborative factory of the future, operating leaner and cleaner for a better future. The business area employs approximately 11,000 people at over 100 locations in approximately 53 countries. go.abb/robotics

Related Story

ABB Opens Refitted, State-Of-The-Art US Robotics Facility, Reaffirming Commitment to North American Customers

ABB has opened its refitted US robotics headquarters and manufacturing facility in Auburn Hills, Michigan, which will support ABB Robotics’ global leadership in developing and manufacturing cutting-edge robotic solutions in the US, for the US and the Americas. The expanded facility reflects ABB’s commitment to long-term growth in the US market, which is predicted to follow global growth rates for robotics of 8% CAGR*, as well as the company’s global investment to build Robotics and Automation capacity and create new, highly skilled jobs. This is ABB’s third global robotics factory expansion in three years across China, Europe and the Americas and is part of its efforts to further strengthen its local-for-local footprint.