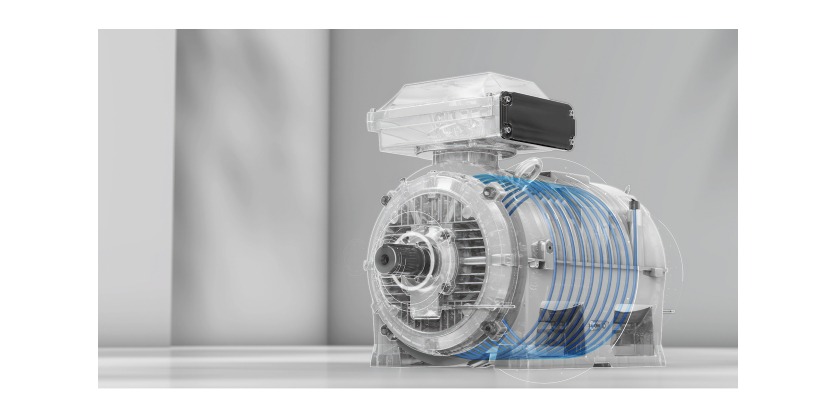

ABB Achieves World First with Liquid-Cooled IE5 SynRM Motor That Sets the Benchmark for Energy Efficiency and High Power Output

February 9, 2024

- New design combines the ultra-premium efficiency of SynRM motors with high performance from liquid cooling previously offered only by induction motors IE5

- SynRM Liquid-cooled motors are ideally suited for applications where high power output in a compact footprint is a critical factor

- IE5 efficiency and excellent reliability optimize the total cost of ownership (TCO) through lower energy consumption and reduced operating and maintenance costs

ABB has achieved another world first for its IE5 SynRM (synchronous reluctance motor) series with the launch of a new version that combines the benefits of ultra-premium energy efficiency with highly effective liquid cooling. The new design sets a new benchmark for high power output and reliability in a compact footprint.

Customers can use IE5 SynRM Liquid-cooled motors to save energy costs and cut emissions in new projects or as a drop-in replacement for less efficient motors. They are ideally suited to a wide range of industries including marine propulsion, rubber and plastics production, and food and beverage.

A major advantage of the IE5 SynRM Liquid-cooled motors is that they are much more efficient than the traditional liquid-cooled induction motors in current use that offer significant potential for upgrading with energy-saving technology. Energy efficiency is crucial to optimizing the total cost of ownership (TCO) of an electric motor because the cost of the energy to run it throughout its life accounts for around 97 percent of a motor’s TCO, with the purchase cost accounting for about two percent. IE5 motors have 40 percent lower energy losses than commonly used IE3 motors. This makes the payback time for selecting an IE5 instead of an IE3 motor often less than one year.

Reliability is improved by highly effective cooling combined with the cool SynRM rotor and cooling ribs on the bearing assembly that reduces the operating temperature of the bearings. This helps to increase the lifetime of this key component and reduce maintenance needs.

The motors are robust, with tight seals to keep out moisture, dirt and dust, and a smooth outer surface to prevent dust build-up. This makes them perfect for demanding applications that require high power density where space is restricted such as marine propulsion systems and thrusters. Furthermore, the motors do not need fans or ventilation, so they do not disturb the surrounding air or release heat into the local environment. This is a major benefit in processes that are impacted by airflow, such as rubber and plastics production, and food and beverage applications like chocolate conche machines. With no fans, the motors also enhance the working environment by reducing noise levels.

Stefan Floeck, Division President IEC Low Voltage Motors, ABB, says: “ABB pioneered both SynRM technology and liquid cooling for induction motors. Now we have brought them together in our IE5 SynRM Liquid-cooled motor that enables customers to enjoy the benefits of ultra-premium efficiency in an even wider range of applications. It is yet another world-first for this series following the launch of our IE5 SynRM Increased Safety motor for hazardous areas.”

The high power output of the liquid-cooled IE5 SynRM offers increased design flexibility. It can enable a machine to be upgraded to deliver a higher power output within the same footprint, or it can allow for a more compact installation footprint while still providing the same output.

The IE5 SynRM Liquid-cooled motors are significantly lighter than competing designs, making them easy to handle and install. A 240 kW IE5 SynRM motor in frame size 315 weighs 870 kg, this is almost half the weight of a corresponding IE3 induction motor.

IE5 SynRM Liquid-cooled motors are available in frame sizes IEC 200-315 in aluminum frames, with steel available on request. The versatile design enables the motors to provide exceptional performance over a range of powers from 37 to 710 kW at 400 V.

ABB (ABBN: SIX Swiss Ex) is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation.

ABB Motion keeps the world turning – while saving energy every day. We innovate and push the boundaries of technology to enable the low-carbon future for customers, industries and societies. With our digitally enabled drives, motors and services our customers and partners achieve better performance, safety and reliability. We offer a combination of domain expertise and technology to deliver the optimum drive and motor solution for a wide range of applications in all industrial segments.Through our global presence we are always close to serve our customers. Building on over 140 years of cumulative experience in electric powertrains, we learn and improve every day. www.abb.com

More Information

More information on SynRM technology

Related Story

Boosting Machine Performance: How Motors, Drives and PLCs Enable Success

By Johann Arndt, Global Product Line Manager Automation, ABB Drives

In today’s competitive market, machine builders face pressure to deliver highly reliable, cost-effective, sustainable and energy-efficient machines. Customers also expect new equipment to be compatible with digitalization and automation technologies. The key to meeting these customer expectations is using high-quality, advanced variable speed drives (VSDs) also known as variable frequency drives (VFDs), or just drives, along with programmable logic controllers (PLCs).