ABB’s Expanded Baldor-Reliance SP4 Technology Now Available in Severe-Duty Enclosures

August 7, 2024

- Severe duty motor achieves NEMA Super Premium (IE4) efficiency; even higher with a variable speed drive

- Severe duty motor achieves NEMA Super Premium (IE4) efficiency; even higher with a variable speed drive

- Reduces motor losses by as much as 20% for significant energy savings

- Extends motor life, reduces maintenance and increases uptime

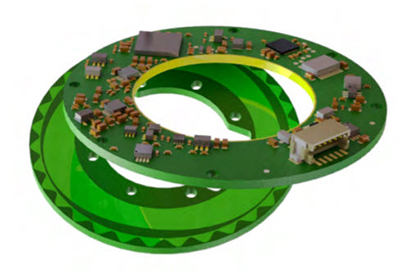

ABB continues to help companies increase motor efficiency by as much as 20% by expanding the ABB Baldor-Reliance® SP4 motor™ line. The development of the new cast-iron totally enclosed fan cooled (TEFC) severe duty motor marks the second phase of ABB’s SP4 technology launch. This model is uniquely designed for applications in hazardous environments with certifications for Division 2 and Class I Groups A, B, C, D, as well as Class II Groups F, and G, making it suitable for areas with explosive gases and combustible dust. The model also features an IP55 rating, ensuring protection against dust and water spray, making it reliable for harsh and dirty conditions.

ABB previously introduced two different models with SP4 technology: rolled steel open drip proof and totally enclosed fan cooled motors.

The SP4 product line builds on the simplicity of ABB’s proven AC induction motors and features a range of durable motors tailored to meet diverse, severe-duty applications. These motors are compatible with pumps, fans, compressors and conveyors and are ideal for all industries. The new cast-iron motors cover a power range of 25 to 300 horsepower, and the rolled steel models, which were launched earlier this year, are available in ¼ to 20 horsepower.

“Reducing electricity consumption benefits communities, businesses and the environment,” said Brandon Canclini, ABB NEMA Motors Division global product manager. “The addition of the ABB Baldor-Reliance SP4 motors doubles down on our commitment to advancing our motor technology and maximizing energy savings.”

More than 80% of industrial electric motors run direct-on-line (DOL), independent of a drive. As a standalone DOL unit, SP4 achieves NEMA Super Premium (IE4) efficiency. The motors become even more efficient when paired with an ABB variable speed drive. SP4 motors run cooler, reducing heat-based energy losses and extending bearing and other component life. Reducing energy losses also leads to lower electrical energy consumption, which lowers operating costs and total cost of ownership.

Available in 2, 4 or 6-pole configurations, SP4 can seamlessly replace existing units to deliver efficiency upgrades for current applications. All SP4 models come with a standard 48-month warranty and are designed to easily replace existing NEMA motors, whether in simple direct-start setups or more advanced variable speed operations.

SP4 motors comply with current U.S. Department of Energy efficiency standards and anticipated Medium Electric Motor (MEM) regulations which take effect June 1, 2027. These regulations require motors up to 100 horsepower to meet NEMA Premium efficiency and motors between 100 and 250 horsepower to achieve NEMA Super Premium efficiency.

More Information

Learn more about ABB’s SP4 technology here.

Related Story

Discover NEMA Motor Upgrade Potential with ABB’s Energy Savings Calculator

Forty-five percent of the world’s electricity is used to power electric motors in buildings and industrial applications.1 By 2030, this cost is projected to reach $900 billion annually.2 Lowering CO₂ emissions and increasing energy efficiency is critical for our planet, but also for ensuring stable and productive industry operations, lowering operating costs and total costs of ownership. To help motor operators better understand the financial and environmental benefits of upgrading current and end-of-life industrial electric motors, ABB has developed its NEMA motors Energy Savings Calculator.