Schneider Electric Receives the 10,000,000th Anybus Module Award from HMS Networks

July 24, 2024

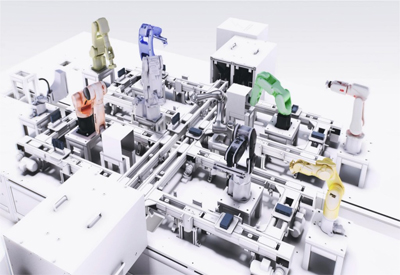

Schneider Electric, a global leader in sustainable energy solutions, has been honored with the 10,000,000th Anybus Module award by HMS Networks. By integrating Anybus network connectivity interfaces into its line of variable speed drives, Schneider Electric empowers its customers with a diverse range of drives that can be fine-tuned for both performance and energy efficiency. This dual benefit not only enhances customer operation performance but also contributes to a greener planet.

Achieving Sustainability: Schneider Electric’s Commitment

Sustainability lies at the heart of Schneider Electric’s mission. The company employs multifaceted strategies to promote a sustainable world. One key approach involves assisting customers in reducing energy consumption while maximizing the impact of the energy they use. As a trailblazer in the transition to a cleaner and more equitable industry, Schneider Electric’s significant contributions to carbon emissions reduction are publicly disclosed every quarter.

Variable Speed Drives and Carbon Emissions Reduction

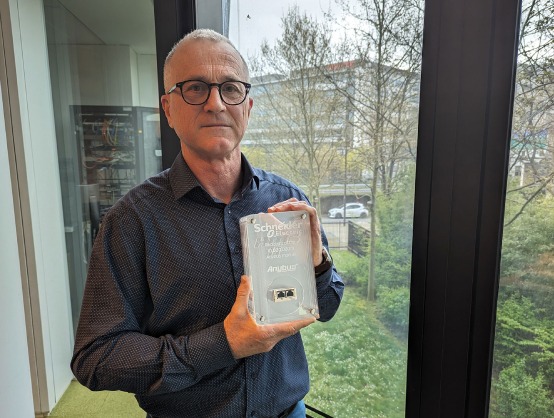

Jean-Louis Guillou, VP Drives – Industrial Control & Drives, highlights the remarkable impact of Variable Speed Drive. Currently, 42% of the total avoided carbon emissions in the Schneider Electric carbon emission report can be attributed to Variable Speed Drives and the more efficient utilization of electrical motors—an achievement that Jean-Louis describes as “absolutely fantastic.”

Enhancing Motor Performance with Smart Drives

Jean-Louis Guillou observes that the trends in drives align with broader industry shifts. Intelligence is increasingly embedded in products, and with each new drive generation, processing power doubles—a deliberate effort to improve monitoring and control to further improve overall efficiency. To achieve optimal motor performance, continuous monitoring and adjustment are crucial. This necessitates smart automation equipment that can be intelligently controlled. In certain industries, up to 50% of total energy consumption is attributed to electrical motors. By employing smart drives to regulate these motors, energy consumption can be reduced by up to 20%, as explained by Jean-Louis Guillou.

A 20-Year Partnership: Schneider Electric and HMS Networks

Schneider Electric and HMS Networks have maintained a strategic partnership for two decades. During this time, HMS Networks has been instrumental in developing network connectivity solutions for Schneider Electric’s popular variable speed drives, enabling seamless connectivity to industrial control networks. These networks span various protocols, including PROFINET, EtherNet/IP, EtherCAT, Modbus TCP, and more. The collaboration between Schneider and HMS Networks has been essential in achieving a solution for supporting multiple industrial communication protocols.

HMS Networks: Pioneering Industrial Network Connectivity

HMS Networks, a leading provider of industrial network connectivity interfaces through its Anybus brand, plays a crucial role in advancing digitalization within the industry. Their communication interfaces support a wide range of industrial network protocols, enabling manufacturers of industrial equipment to seamlessly connect to any type of network without the burden of in-house development and maintenance. By partnering with HMS Networks, companies like Schneider Electric can offer their customers world-class and reliable network connectivity.

Connectivity: A Vital Requirement for Efficiency and Sustainability

As the world moves toward greater efficiency and sustainability, digitalization is becoming ubiquitous. Connectivity is no longer a luxury—it’s a necessity. In the future, everything will be interconnected. Schneider Electric and HMS Networks share a vision of continued collaboration to drive this transformation forward.

Jean-Louis Guillou, Vice President for Schneider Drives division, sums it up: “Digitalization is happening all around us. Connectivity isn’t just nice to have; it’s an essential requirement. Let’s continue working together to shape a connected and sustainable future.”

Video interview with Jean-Louis Guillou

HMS Networks AB (publ) is a market-leading provider of solutions in industrial information and communication technology (Industrial ICT) and employs over 1200 people. HMS develops and manufactures products under the Anybus®, Ixxat®, Ewon®, and Intesis® brands (Red Lion® Controls is also a part of the HMS Group as of April 2024). Local sales and support are handled by branch offices all over the world, as well as through a worldwide network of distributors and partners. HMS reported sales of SEK 3,025 million in 2023 and is listed on the NASDAQ OMX in Stockholm in the Large Cap segment and Telecommunications sector.

More Information

Related Story

Annual Analysis Reveals Steady Growth in Industrial Network Market – Industrial Network Market Shares 2024 According to HMS Networks

Every year, HMS Networks conducts a comprehensive analysis of the industrial network market, aiming to estimate the distribution of new connected nodes by type and protocol within factory automation. The latest study indicates that the industrial network market continues to expand, with an anticipated 7% growth in 2024. Notably, Industrial Ethernet remains the dominant player, representing a substantial 71% of all newly installed nodes (compared to 68% last year). Meanwhile, fieldbuses have declined to 22% (from 24%), and wireless technologies have seen a slight dip from 8% to 7%. Among the top contenders, PROFINET account for 23% of newly installed nodes, followed closely by EtherNet/IP at 21%, and EtherCAT now stands at 16%.