NSK Receives Tribology Technology Award for Technology Enhancing Bearing Durability

October 17, 2022

NSK has received the “Japanese Society of Tribologists (JAST)*1 Technology Award” for new technology improving the durability of bearings by strengthening the rolling elements (steel balls).

The award-winning rolling element reinforcement technology is already being used in bearings for automotive transmissions and machine tools, contributing to improved reliability in a wide range of machinery.

Moving forward, NSK will continue to draw on its world-class research and development capabilities to create a safe, comfortable, and environmentally friendly society, and support industrial development and the advancement of machinery.

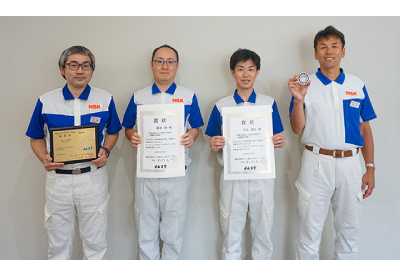

NSK engineers awarded for development of new technology. (From left) Hiroki Komata, Sho Hashimoto, Yasuhiro Iwanaga, Toru Ueda

*1: JAST was established in 1956 for the purpose of improving technologies relating to tribology (the science and technology of interacting surfaces in relative motion and of related subjects and practices).

In recent years, the demand for energy savings in industrial machinery has been increasing in order to achieve carbon neutrality, and rolling bearings are required to meet the needs of society by achieving further weight reduction and lower torque. Against this backdrop, the loads applied to rolling bearings and lubrication conditions are becoming more severe, and there is concern about the occurrence of flaking damage or failure due to rolling contact fatigue.

NSK’s ongoing research on rolling contact fatigue has led to the discovery of a new strengthening mechanism that extends the durability life of the bearing itself by strengthening the rolling elements. Based on the research, NSK developed a rolling element (steel ball) with high resistance to surface degradation by forming fine precipitates in the surface structure of the steel. The crystal structure of the precipitates is different from that of the steel matrix, and thereby give the superior resistance against wear and dent formation. The use of this new rolling element makes it possible to increase the durability of bearings.

To learn more, visit NSK’s website by clicking here