ABB Partners With Seaspan Shipyards on New Canadian Coast Guard Polar Icebreaker

March 6, 2024

ABB has secured a comprehensive propulsion system contract with Seaspan’s Vancouver Shipyard for the first of the Canadian Coast Guard’s new-generation polar icebreakers

- ABB has secured a comprehensive propulsion system contract with Seaspan’s Vancouver Shipyard for the first of the Canadian Coast Guard’s new-generation polar icebreakers

- The icebreaker is expected to be the world’s largest and most powerful diesel-electric icebreaker when it enters service in 2030

- Azipod® propulsion has been selected to support the vessel’s operational efficiency, reliability and icebreaking capability, meeting tightest emissions regulations

Seaspan Shipyards, Canada’s long-term shipbuilding partner for the Canadian Coast Guard (CCG) and Royal Canadian Navy, has awarded ABB a contract to deliver an integrated propulsion system for the first of the CCG’s new-generation polar class icebreakers.

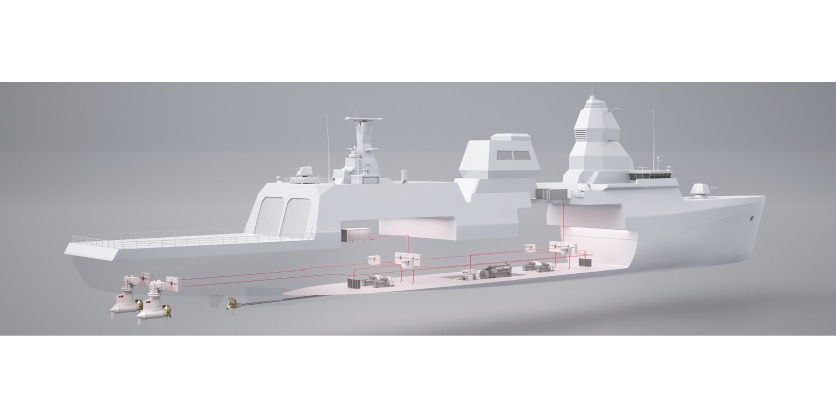

The vessel is expected to be one of the world’s largest and most powerful diesel-electric icebreaker when it enters service in 2030, with ABB supplying vessel systems complying with IACS Polar Class 2 requirements for year-round operations in moderate multi-year ice conditions. The vessel will have 34MW of propulsive power provided by a single shaftline and twin Azipod® units. In addition to increasing efficiency and reliability, Azipod® propulsors offer improved maneuverability in icy waters.

This major marine systems order marks a significant milestone for ABB in Canada, with ABB assuming the role of single system integrator responsible for the engineering, delivery and commissioning of the comprehensive propulsion package.

Upon delivery, the vessel will join a reference list of 150 other icebreaking or icegoing vessels outfitted with ABB’s propulsion technology. As the first vessel of its kind to be built in Canada in over 60 years, it will set a performance benchmark for the new generation of domestically built coast guard icebreakers.

The vessel will be constructed under Canada’s National Shipbuilding Strategy (NSS), the nation’s long-term commitment to renew the Canadian federal fleet. With Canada’s current largest icebreaker, the CCGS Louis S. St-Laurent, set to retire at the end of the decade, the new vessel will be an important addition to the CCG fleet. In addition to patrolling the Canadian coastline, the vessel’s duties will include supporting Arctic science and research, environmental response, and search and rescue operations. Compared to its predecessor, the new flagship of the icebreaker fleet will be able to operate for longer periods of time in challenging weather conditions.

“ABB’s proven technology, along with their valuable insight, made them a natural fit for this project. We have been pleased by the support and consultation Seaspan has received so far and look forward to more excellent collaboration moving forward,” said Leo Martin, Senior Vice President, Programs, Seaspan Shipyards.

“The Canadian Coast Guard eagerly awaits the construction of the polar icebreakers, which will extend our on-water operations and ensure the continuous delivery of critical services in the high Arctic. This includes search and rescue, environmental and humanitarian response, as well as playing a key role in supporting ocean science. Congratulations to Seaspan Shipyards and ABB on striking this new partnership,” said Mario Pelletier, Commissioner, Canadian Coast Guard.

“The newbuild polar icebreaker is an important part of Canada’s National Shipbuilding Strategy, and it is an honor for ABB to have been selected as a strategic partner and to contribute to this project with our innovative technology and solutions, expertise and experience. We look forward to working with Seaspan’s Vancouver Shipyards during construction of the vessel, and to supporting the Canadian Coast Guard in its operations,” said Markus Astor, Head of ABB Marine & Ports, Canada.

ABB’s growth in the naval and coast guard sector continues to expand. Between 2017 and 2020, the CCG partnered with ABB on modernization efforts to extend the lifespan of nine CCG vessels, and, in 2021, ABB received a National Individual Standing Offer (NISO) to provide those vessels with full-scope services for the equipment installed onboard. In 2019, the Norwegian Coast Guard’s KV Svalbard became the first ever Azipod®-powered ship to reach the North Pole. In April 2023, ABB was awarded a contract by the Finnish Border Guard for the supply of an integrated power and propulsion package for two newbuild patrol vessels.

ABB’s Process Automation business automates, electrifies and digitalizes industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimize how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation. www.abb.com

More Information

Related Product

ABB Azipod Icebreaking Propulsion to Power a Fleet of Newbuild LNG Carriers

ABB has recently secured a contract from Daewoo Shipbuilding & Marine Engineering in excess of $300 million to supply a comprehensive power and propulsion package for six new specialized vessels that will transport LNG along the Northern Sea Route.

Each of the six newbuild vessels will feature a trio of the largest and most powerful Azipod propulsion units ever supplied for ships operating in ice. Together, the giant 17 MW Azipod® units will provide a total power of 51 MW (68,400 HP), enabling the vessels to navigate safely through ice up to 2.1 m thick. In similar conditions and without ABB’s leading technology, comparable ships would require icebreaker assistance.