ABB Partners With Energy Control Technologies to Design Integrated Turbomachinery Controls Solution

September 26, 2024

- ABB signs Joint Development Agreement with Energy Control Technologies to integrate turbomachinery controls into the ABB Ability™ System 800xA® distributed control system

- New solution allows customers to bring industrial plants and assets online quickly and cost-effectively using single interface

- Integrated Compressor Controls improve energy efficiency, reduce system footprint and contribute automation and electrical CAPEX reductions of up to 20 percent for integrated projects

ABB has signed a joint development agreement with US company Energy Control Technologies (ECT) to co-design and deliver an integrated turbomachinery controls solution which can be configured, operated and maintained within the ABB Ability™ System 800xA® distributed control system (DCS).

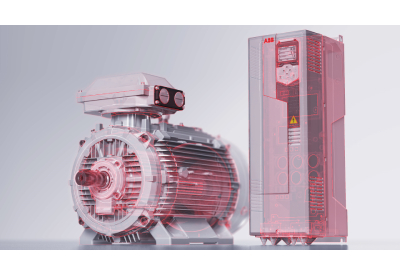

The ABB-ECT Integrated Compressor Controls (ICC) with Integrated Control Safety System (ICSS) offers customers a flexible solution that aims to reduce the footprint and complexity of their plant control system and will have the potential to contribute to automation and electrical CAPEX reductions of up to 20 percent for integrated projects, according to ABB estimates.

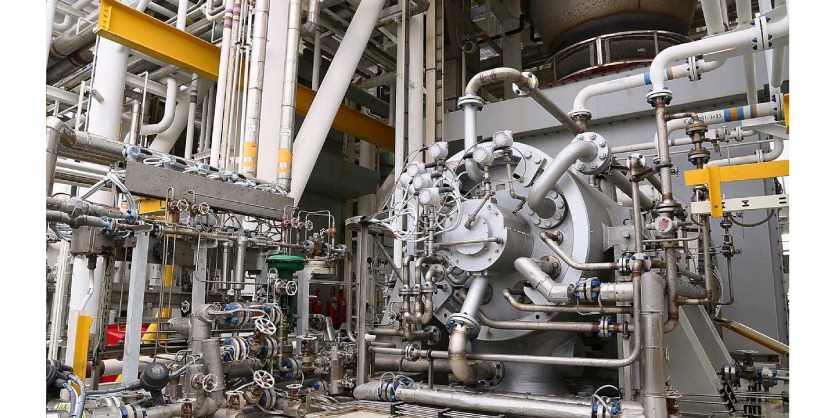

Turbomachinery, which is widely employed in industries including hydrogen, biofuels, carbon capture and storage, power generation and oil and gas, consumes large amounts of energy. Having integrated controls provides greater visibility to better manage the performance of the equipment and in turn increase energy efficiency, while reducing risk and cost.

The ABB-ECT ICC is achieved by eliminating traditional black box controls from the system architecture and having controls unified within the same 800xA ICSS System. The need for a separate operator workstation, I/O network, servers, networks, switches and other auxiliary systems is removed. This provides faster startup and greater machine protection, safety and stability.

Until now, installing turbomachinery controls has involved multiple systems, often from different suppliers, that need to be interfaced. Now, operators can benefit from one common platform, for both compressor and DCS controls, from which they can monitor the most critical and expensive assets of their plants – turbines, compressors, pumps and generators.

“We are pleased to collaborate with ABB on this innovative solution which will further help customers solve their most complex control issues across many sectors relying on turbomachinery,” said Paul Fisher, President at ECT. “ECT’s superior compressor control algorithms and technology integrated into the ABB Ability™ System 800xA® DCS will allow customers to run their turbomachinery control system in automatic all the time, providing users with increased production, energy efficiency, and machine protection.”

“This collaboration marks a significant development within the integrated turbomachinery control solutions market and we’re excited to already see uptake from some major US customers, with plans to roll out worldwide,” said Per Erik Holsten, President of ABB Energy Industries. “Turbomachinery is essential to industry but ongoing innovation is necessary to enhance energy efficiency. Leveraging ABB’s technology presents an immediate opportunity to achieve our goal of helping customers to reduce energy demand by optimizing industrial processes.”

Under the agreement, ABB is providing the hardware, software and technical support for ECT to develop the turbomachinery solution for the 800xA platform, while ECT is providing the turbomachinery control algorithm and engineering design, among other assets.

Related Story

ABB Provides Power Management System for BHP’s Jansen Potash Project in Canada

ABB has been selected by BHP to deliver a power management system for the Jansen Potash Project in Canada, which will provide nutrient-rich potash fertilizer to enable more sustainable farming globally. The global resource company is progressing the US $5.7 billion Jansen Stage 1 Potash Project which is expected to achieve first production in late 2026.

The order includes ABB Ability™ System 800xA Power Control Library, a digital application to monitor industrial electrical systems. It will help BHP on its journey towards an automated, electrified and digitalized site where engineers can monitor and quickly troubleshoot disturbances. The system will cover the electrical substation equipment remotely, reducing the time taken for fault diagnosis and problem solving.