ABB and Sage Geosystems Unearth Geothermal Energy Opportunities

February 5, 2025

- ABB and Sage Geosystems partner on developing Geopressured Geothermal Systems for low carbon energy storage and geothermal power generation

- Collaboration scope to include delivering geothermal power to support data center growth

- In the US alone, geothermal energy has the potential to capture enough natural heat resources to power more than 65 million homes

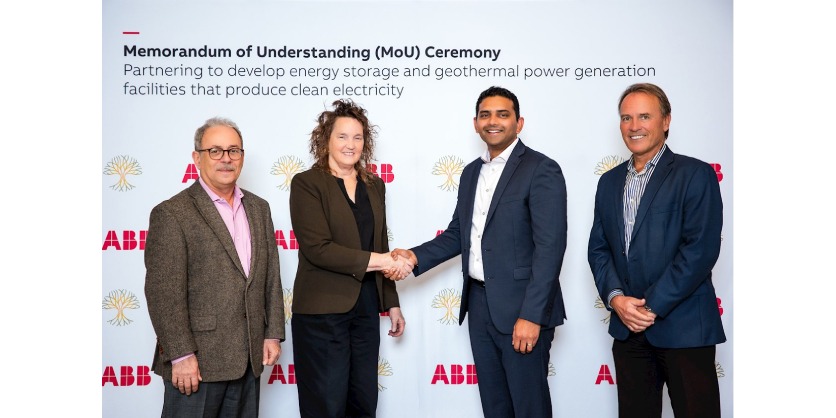

ABB and Sage Geosystems (Sage), a leading geothermal baseload and energy storage company, have signed a Memorandum of Understanding (MoU) agreement to collaborate on developing energy storage and geothermal power generation facilities that utilize natural heat from the earth’s core to produce clean electricity.

The collaboration will allow ABB to support Sage’s agreement with Meta, the parent company of Facebook and Instagram, to deliver up to 150 MW of geothermal baseload power at a location east of the Rocky Mountains in the US. The first phase of the project is expected to be operational by 2027.

Within the main MoU scope, ABB will investigate how its automation, electrification and digital technology can be deployed at geothermal sites around the world, to maximize energy efficiency and reliability. This may include supplying a distributed control system (DCS), electrical infrastructure architecture, and digital solutions such as asset performance management, process optimization and cybersecurity systems. The partnership also has the potential to develop solutions for Sage’s energy storage technology, which can be paired with intermittent renewable resources such as solar and wind.

“We are focused on scaling our proprietary Geopressured Geothermal Systems (GGS) technology and our partnership with ABB will advance the widespread deployment of next-generation geothermal,” said Cindy Taff, CEO of Sage Geosystems. “Unlike traditional renewable energy sources, geothermal solutions, including energy storage and baseload power generation, can provide an on-demand source of clean energy that is available 24 hours a day, 365 days a year.”

Geothermal energy has the potential to be an important contributor to the future energy mix, with enhanced geothermal systems emitting little to no greenhouse gases1. The GGS process involves pumping fluid at pressure into a man-made subsurface reservoir. After the stored water is heated to more than 150°C and, leveraging pressure or mechanical energy, it can be released back to the surface to pass through heat exchangers and turbines to generate electricity. In the US alone, it is thought that geothermal energy could capture enough natural heat resources to power more than 65 million homes2.

“To be able to exploit the potential of geothermal energy to enable a low-carbon society, we need cross-industry collaborations to drive advancements in the technology,” said Per Erik Holsten, President of ABB Energy Industries. “Sage’s GGS offers the ability to produce low carbon electricity, as well as an energy storage solution, and can play an important role in the energy transition alongside other measures.”

Geothermal energy is set to build on the current 0.3 percent market share of the world’s power supply, according to Rystad Energy3. Installed geothermal capacity stands at 16.8 GW worldwide currently, but this is expected to reach 28 GW by 2030 and upwards of 110 GW by 2050. The market growth trajectory is expected to attract investments totaling over $120 billion between now and 2035.

ABB is a global technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. By connecting its engineering and digitalization expertise, ABB helps industries run at high performance, while becoming more efficient, productive and sustainable so they outperform. At ABB, we call this ‘Engineered to Outrun’. The company has over 140 years of history and around 110,000 employees worldwide. ABB’s shares are listed on the SIX Swiss Exchange (ABBN) and Nasdaq Stockholm (ABB). www.abb.com

Endnotes

- https://www.iea.org/articles/capturing-the-energy-beneath-our-feet

- https://www.energy.gov/eere/articles/doe-analysis-highlights-opportunities-expand-clean-affordable-geothermal-power

- https://www.rystadenergy.com/insights/geothermal-market-teed-up-for-accelerated-growth-in-coming-years

More Information

Related Story

The Drive Towards Energy-Efficient Data Centres

Data centres are the backbone of our digital world. They serve as the foundation for various online activities like streaming, e-commerce, and website/app usage. In today’s tech-driven world, our attention is actively captured by our online activities, all of which heavily depend on data centres.

The demand for storage and processing is skyrocketing, further propelling this growth is the rapid adoption of emerging technologies such as artificial intelligence, machine learning and big data analytics. The Internet of Things (IoT), which connects the digital and physical worlds through a network of sensors, and the rollout of 5G networks for mobile devices will fuel the exponential growth of data centres.