Motion Control Technology Primer

October 2, 2023

What makes a bus based Motion Controller deterministic? What are the three types of Step Motors? What is the difference between an Absolute Encoder and a Resolver?

These questions (and many more) are quickly answered Motion Control Technology Primer.

The Primer covers the following topics:

- Motion Control

- Motion Controllers

- Drives and Amplifiers

- Motors

- Feedback Sensors

- Mechanical Systems

Motion Control

A sub-field of automation in which the position, velocity, force or pressure of a machine is controlled using some type of pneumatic, hydraulic, electric or mechanical device. Some examples include a hydraulic pump, linear actuator, electric motor or gear train.

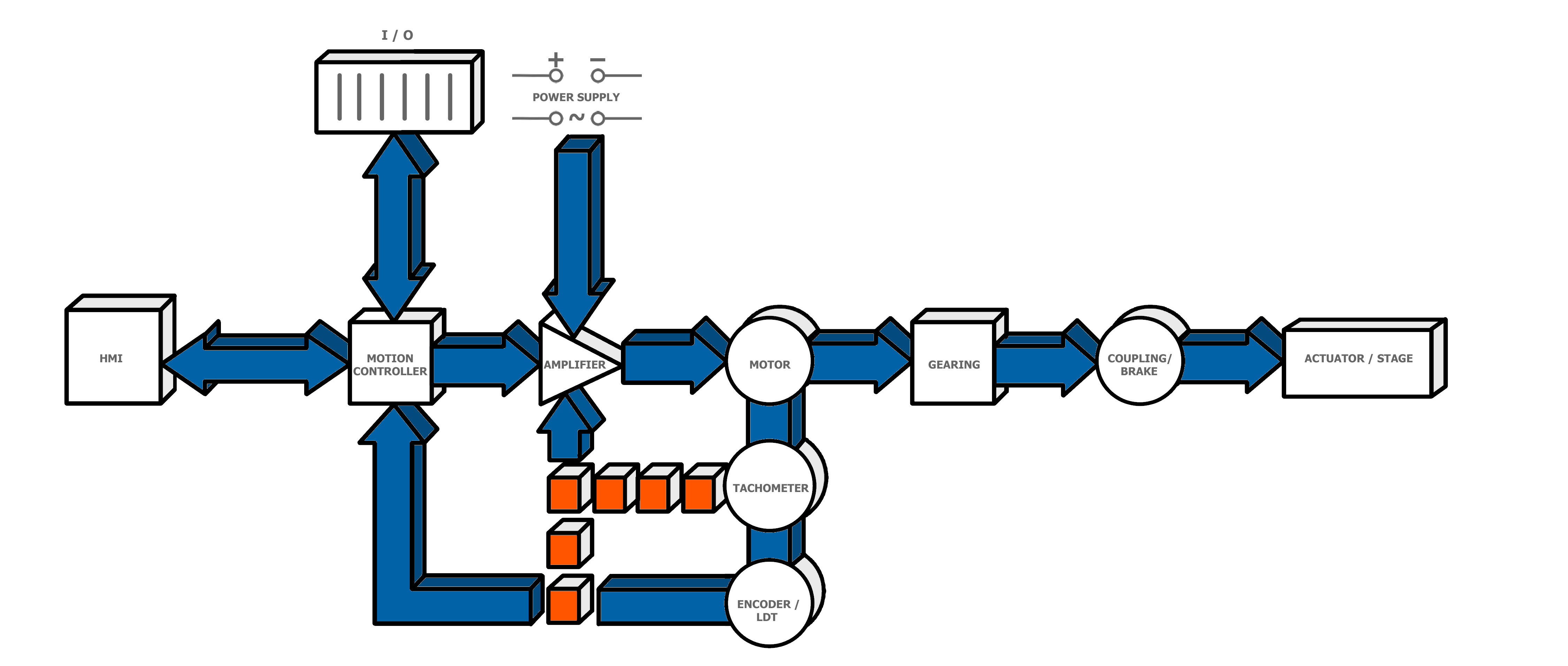

Motion Control System

A motion control system is a system that controls the position, velocity, force or pressure of some machine. As an example, an electromechanical based motion control system consists of a motion controller (the brains of the system), a drive (which takes the low power command signal from the motion controller and converts it into high power current/voltage to the motor), a motor (which converts electrical energy to mechanical energy), a feedback device (which sends signals back to the motion controller to make adjustments until the system produces the desired result), and a mechanical system (including actuators, which physically produce the desired end result).

Types of Motion Control Systems

- Open Loop System – A system that does not use feedback to verify the desired result, or output, has been reached. Most step motor systems are operated open loop.

- Closed Loop System – A system that uses feedback to verify the desired result, or output, has been reached. As an example, a feedback device such as an encoder is commonly used to provide position or velocity information to a motion controller. A servo motor system requires the use of a feedback device.

Motion Controller

A motion controller is the primary intelligence, or brain, within a motion control system. It is responsible for calculating and generating the output commands for a desired motion path or trajectory. Motion controllers vary in complexity; sophisticated motion controllers typically consist of a trajectory generator (path planner), interpolator, and control loop for servo motor control. A step generator block is added when used for stepper motor control.

- Trajectory Generator/ Path Planner – The trajectory generator calculates the segments, or set points, of a motion path based on the desired target position, maximum velocity, acceleration, deceleration and jerk. It determines how much time is spent in the three primary segments of a move: acceleration, constant velocity and deceleration.

- Interpolator – Algorithm within the motion controller that calculates fi nely spaced positions from the set points generated by the trajectory generator. Th is is typically performed by some form of a cubic spline equation. Th e results of the interpolator are fed into the control loop.

- Control Loop – Algorithm within the motion controller that calculates an error signal based on the diff erence between the expected and actual position/velocity. Motion controllers typically use a PID (proportional, integral, derivative) algorithm with enhancements for more advanced control capabilities. Th e gain settings for the PID dictate the responsiveness of the control loop.

- Step Generator- Algorithm within the motion controller that precisely generates digital step command pulses to meet the desired motion path.

Types of Motion Controller Topologies

- PLC Based – PLC based motion controllers typically utilize a digital output device, such as a counter module, that resides within the PLC system to generate command signals to a motor drive. They are usually chosen when simple, low cost motion control is required but are typically limited to a few axes and have limited coordination capabilities.

- PC Based/ Computer Bus Based – PC based motion controllers typically consist of dedicated hardware run by a real-time operating system. They use standard computer busses such as PCI, PXI, Serial, USB, Ethernet, and others for communication between the motion controller and host system. PC based controllers generate a ±10V analog output voltage command for servo control and digital command signals, commonly referred to as step and direction, for stepper control. PC based motion controllers typically are used when high axes count and/or tight coordination is required. The drawbacks of this topology include complex cabling and potentially long wiring distances between the drive and motor.

- Fieldbus Based – A fieldbus based motion controller topology consists of a communication interface device and intelligent drive(s). The communication interface device typically resides within a PLC or PC system and connects to a single or multiple intelligent drives. The drives contain all the functionality of the motion controller and function as a complete single axis system. Often the drives can be daisy chained to other intelligent drives on the same fieldbus. The benefi ts include all digital communication, detailed diagnostics, reduced cabling, high axes count and short wiring distance between the drive and motor. This topology has a higher cost especially at lower axes count and is not capable of tight coordination for multiple axes. Examples of this topology include Profibus, DeviceNET, RS-232/485, and others.

- Deterministic Bus/Motion Network – A deterministic bus based motion controller topology splits the motion controller functionality across a communication interface device and intelligent drive via a deterministic digital network. The communication interface device typically resides within a PLC or PC system and contains the trajectory generator. The intelligent drives typically contain the control loop and interpolator and can be daisy chained to other intelligent drives on the same network. The digital network is deterministic with low jitter to allow for tight coordination in multi axes applications. The benefits include all digital communication, detailed diagnostics, reduced cabling, high axes count, tight coordination, and short wiring distance between the drive and motor. This topology has a higher cost especially at lower axes count. Examples of this topology include EtherCAT, SERCOS, PROFINET IRT, SynqNet, CANopen, and others.

Deterministic: an important attribute which indicates that a message or data reaches its destination in a specific, predicable time. Time critical data transfer must be guaranteed within short and precise configurable cycles, while less critical data can be transmitted in asynchronous time slots. Data reaching its destination at guaranteed times is critical for motion control.

Drives & Amplifiers

Drives and amplifiers transform the low power command signal from the motion controller into high power current/voltage to the motor. The terms drive and amplifier are interchangeable.

- Digital versus Analog Drives – Digital drives contain some form of processing capability, typically a Digital Signal Processor (DSP). Analog amplifi ers or drives have little to no processing capability and perform all the drive functionality strictly in the analog domain. Due to the additional intelligence available on digital drives they have more functionality, diagnosis capabilities, and easier confi guration compared to analog drives.

- Linear Drive – A drive in which the output is directly proportional to either a voltage or current input. Linear drives are very ineffi cient and are typically only used for low power applications. Th eir main advantage is they provide a very electrically quiet, low noise, output as compared to switching drives.

- Switching Drive – Also known as a PWM or chopper drive. A drive that switches a voltage on and off to control current/voltage, usually in the form of Pulse Width Modulation (PWM). Provides very high effi ciency and smaller physical size compared to a linear drive but is electrically noisy.

- Microstepping Drive – A drive that applies power to the appropriate step motor winding to produce torque. It precisely divides the current between the motor phases thus positioning the step motor at smaller increments between full steps. It provides higher resolution but with less torque. Microstepping improves low speed smoothness, minimizes low speed resonance eff ects, and produces smooth rotation over a wide speed range.

- Servo Drive – A drive that converts a low level ±10V analog command signal from a motion controller into high power current/voltage to the servo motor windings to produce torque. A servo motor drive utilizes internal feedback loops for precise control of motor current and may also control velocity.

- Intelligent Drive/Smart Drive – A drive that combines a portion, or all, of the motion controller functionality with the high power electronics of a motor drive. Smart drives vary with the amount of control functionality and type of communication interface. Th ere are generally two types: fi eldbus based and deterministic bus based. Fieldbus based intelligent drives contain all the components of a motion controller and are communicated to via a serial port or a fi eldbus network. Th ey are typically used for non coordinated motion control applications. Deterministic bus based intelligent drives typically incorporate the interpolation and control loop into the drive but rely on a motion controller to perform the trajectory generation. Th e benefi ts of either intelligent drive topology include all digital communication, detailed diagnostics, reduced cabling, high axes count and short wiring distance between the drive and motor.

Motors

- Commutation – Act of precisely switching, or sequencing, current in a motor’s windings, or phases, to obtain rotation. This function is performed mechanically by a commutator for DC motors. It is performed electrically by the drive for brushless and step motors.

- DC Motor/ Brushed Motor – Motors that have winding in the rotor and permanent magnets on the stator. Carbon brushes and a mechanical commutator provide a current path through the windings to achieve motor torque. A DC motor will continuously rotate if a DC power source is applied across its terminals. DC motors require simpler drives but require higher maintenance, and are larger in size for the same output power.

- Brushless Servo Motor – Motors that have windings in the stator and permanent magnets attached to the rotor. No brushes are used. Motor rotation is achieved by means of electrical commutation performed by the drive. Brushless servo motors provide high acceleration, high torque, and no maintenance.

- Linear Servo Motor – A linear motor provides direct linear motion (rather than rotary). Electromagnetic force is utilized to produce thrust directly, eliminating the need for rotary to linear conversion. Advantages include: high speeds, high precision, fast response, stiff ness, zero backlash and maintenance free operation. Disadvantages include: higher cost, required higher bandwidth, larger footprint and heat. Types: Iron core, air core, slotless.

- Step Motor – Motor with windings in the stator and permanent magnets attached to the rotor. It provides fi xed mechanical increments of motion; these increments are referred to as steps and are generally specified in degrees. A step motor, in conjunction with a stepper drive, rotates in predefined angles proportional to the digital input command (stepper) pulses. A typical full-step system achieves 200 steps per revolution, this equates to 1.8º per full step. Step motors provide acceleration torque equal to running torque and require no maintenance. They have limited operation at high speeds, run hot, and can stall with excessive loads.

- Types of Step Motors – There are three types of step motors:

- Variable Reluctance: Has teeth on the rotor and stator but no rotor permanent magnet.

- Permanent Magnet: Has a permanent magnet for a rotor but no soft iron rotor teeth.

- Hybrid: Combines the magnet from the permanent magnet motor and the rotor and stator teeth from the variable reluctance motor.

- Types of Step Motors – There are three types of step motors:

Feedback Sensors

A class of devices required for closed loop operation. Th ey provide a signal back to the drive or motion controller to monitor an operation or process and verify that proper operation occurs.

- Encoders – An electromechanical device for translating linear or rotary displacement into a corresponding series of digital signals or analog output voltage.

- Incremental Encoder – A device that generates electrical signals by means of a rotating disk that passes between a light source and photo detectors. Incremental encoders have two output signals, or channels, commonly referred to as A and B. The A and B outputs are nominally 90º out of phase with each other and are interpreted by a motion controller to determine position/velocity information. The lead/lag relationship between the A and B channels provides directional information. It is important to understand that each mechanical position is not uniquely defined. When the incremental encoder is powered on, the position of an incremental encoder is not known, since the output signals are not unique to any singular position. Incremental encoders often provide a third output that pulses once per revolution of the disk. This is typically called the Index, or Z-channel, and is commonly used for homing/reference moves.

- Absolute Encoder – Absolute encoders have a unique value (voltage, binary count, etc.) for each mechanical position. When an absolute encoder is powered on, the position is known. Absolute encoders most commonly provide digital data in a parallel or serial format to the motion controller which is used to determine position/velocity information. Since they provide absolute position information when powered on they eliminate the need for a homing/reference move in a motion system.

- Resolvers – A resolver is a feedback device whose construction is similar to a motor (stator and rotor). It uses four wires to carry an encoded angle and produces two alternating voltages whose amplitudes or phases depend on the shaft rotation angle. It provides absolute position information and can be used by the motion controller to determine position/velocity information.

- Hall Effect Devices – A Hall eff ect sensor is a transducer that varies its output voltage in response to changes in magnetic field density. Hall sensors are used for proximity switching, positioning, speed detection, and current sensing applications. They are often used on brushless servo motors to provide positioning information for the drive to commutate the motor.

Mechanical System

The part of a motion control system that produces the desired motion. The mechanical system can include actuators, motors and hydraulic devices.

- Actuator – A device that creates physical movement by converting various forms of energy to rotary or linear mechanical motion.

- Linear Actuator – A device that converts various forms of energy to linear motion.

Types of Linear Actuators

- Lead screw actuators: A lead screw actuator with a threaded nut that moves with a screw. It provides both simple construction and lowest cost.

- Ball screw actuators: A lead screw actuator that uses ball bearings; more expensive but less friction compared with lead screw actuators.

- Planetary roller screw actuators: A lead screw actuator that uses threaded rollers surrounding the main threaded shaft; the most expensive option but also the most durable.

- Belt Actuators: Actuators based on belt drives; often used where speed is important but with limited accuracy.

- Rod type: The thrust element or rod moves out of the end of the actuator as motion takes place; produces more force and highly tolerant of dirty environments but require a structure to carry the load.

- Rodless type: Th e actuator housing completely surrounds the screw which provides a load bearing and guidance structure. Rodless actuators are diffi cult to seal for dirty or wet environments.

- Integrated Actuators: Integrates the actuator into the motor to eliminate the need for a coupling. Integrated actuators provide lowest size and weight and easier maintenance but are typically higher cost.