SEW-EURODRIVE: MOVIGEAR – The Mechatronic Drive System

April 27, 2020

In many industries, such as the automotive, food and beverage industry, airport logistics or general intralogistics, the demands on materials handling systems are becoming both more complex and more specific. At the same time, less installation space is available for meeting these demands. This is why SEW-EURODRIVE researches and develops ideal application solutions. The result is the mechatronic drive system MOVIGEAR. It has an advantageous, compact design and is ideal for ensuring that conveyor systems are structured efficiently.

The housing has been optimized specifically for these types of applications and can be easily integrated in today’s conveyor systems. It also enables new developments to be implemented from a completely new perspective. This technology masters high break-away and acceleration torque levels after longer system downtimes time without any limitations. The power required to drive the system can be reduced significantly.

MOVIGEAR is the next logical step in the development of the economically and technically successful concept of decentralized drive systems.

Mechatronic drive system comprising motor, gear unit and electronics

A systematic development approach was taken right from the design phase. MOVIGEAR impresses with its high level of system efficiency, which in turn helps lower the energy costs. The integration and coordination of all the drive components leads to a long service life and high system availability.

MOVIGEAR is an intelligent device with its own control concept. Its high-quality networking features help reduce the startup time and support the monitoring and maintenance tasks. Drive tasks can be solved quickly and easily using the corresponding application software.

Your benefits at a glance

- – Compact design: Motor, gear unit and electronics are combined in a single mechatronic drive system

- – Simplified system planning and design

- – A reduction in the number of variants allows for developing and designing standard materials handling systems with pre-fabricated and tested standard modules.

- – The power of the drive engineering components is optimized to suit the application

- – Reduction in storage due to reduced number of variants

- – High degree of protection

- – Hygienic surface design for applications in hygienic areas

- – No air, dirt and germ swirls

- – Low noise emission due to operation without fans (suitable for use in manual work stations)

- – Reduced energy costs due to high efficiency of all components (gear unit, motor, electronics)

- – High degree of reliability due to systematic development of all components

- – Reduced total costs and operating costs of the materials handling system

MOVIGEAR drive units

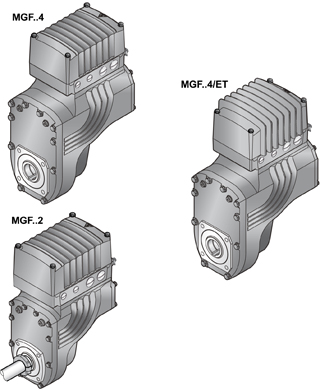

MOVIGEAR is available in 3 sizes and 2 mechanical designs. For more information, see the section “Technical data and dimension sheets.”

MOVIGEAR sizes

- – MGF.2 (torque class: 200 Nm)

- – MGF.4 (torque class: 400 Nm)

- – MGF.4/ET = “Expanded torque” option (expanded rated motor torque in continuous duty) (torque class: 400 Nm)

MOVIGEAR versions

- – MOVIGEAR with hollow shaft and keyway

- – MOVIGEAR with TorqLOC hollow shaft mounting system

Examples

The following figure shows a MOVIGEAR MGFT.2 unit with TorqLOC hollow shaft mounting system and a MOVIGEAR® MGFA.4 and MGFA.4/ET unit with hollow shaft and keyway:

General unit properties

- – Wide voltage range 3 x AC 380 V to AC 500 V

- – High overload capacity for all sizes

- – 4Q capability due to integrated brake chopper and braking resistor installed as standard

- – Line filter integrated as standard. EMC-compliant installation ensures compliance with limit class C3 to EN 61800-3 (class A, group 2 according to EN 55011).

- – LED display for operating and fault states

- – Protective features for complete protection of the frequency inverter and motor (short-circuit, overload, overvoltage/undervoltage, excess temperature in the frequency inverter, excess temperature in the drive unit).

- – IPOS integrated positioning and sequence control

- – Integrated STO safety function

- – STO (safe torque off according to IEC 61800-5-2) by disconnecting the STO input.

- – Performance level e according to EN ISO 13849-1.

- – SS1(c) (safe stop 1, function variant c according to IEC 61800-5-2) by means of suitable external control (e.g. safety relay with delayed disconnection)

You find the specific unit properties of DBC-B, DAC-B, DSC-B and SNI-B in the subsequent chapters.

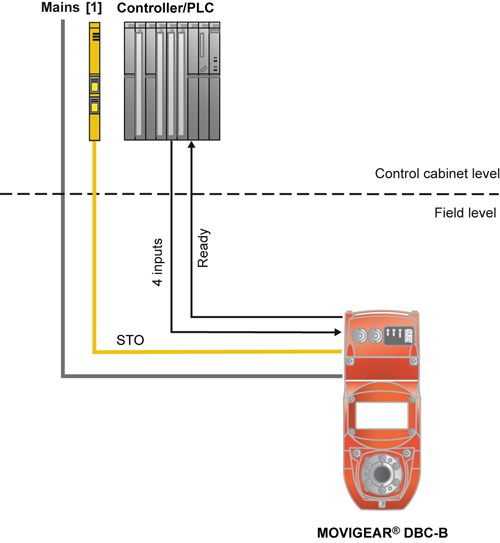

MOVIGEAR DBC-B – Direct Binary Communication

SEW-EURODRIVE has developed the mechatronic drive solution MOVIGEAR DBC-B specifically for stand-alone applications and for applications with simple functionalities. DIP switches and potentiometers allow for simple and fast startup – without the need of a PC. The unit is controlled via the binary inputs either by a central PLC or in local/manual mode.

Characteristics

- – Simple startup without PC via DIP switches and potentiometer

- – Parameterizable fixed speeds and ramps

- – Binary input control and signal relay evaluation via PLC

- – Local mode via binary inputs

- – Interface for diagnostics and parameterization

Fields of application

- – Simple stand-alone applications and single applications

- – For applications that require soft start-up behavior

- – Applications with 2 fixed speeds

- – For applications with high breakaway torques

- – Applications with/without STO safety function

Application examples

- – Simple conveyors

- – Rotary tables

- – Drives for infrequent speed variations

- – Agitators and mixers

- – Crushers and shredders

- – Presses

Installation principle

The figure to the left shows the principle of MOVIGEAR DBC-B.