White Paper: How Can Low-Voltage Controls Contribute to Energy Efficiency?

May 31, 2021

Anyone who has been following the latest expert discussions on energy efficiency in machines and plants will have noticed that certain topics come up time and time again. The main examples are “variable frequency drives for optimum drive solutions” and “increasing efficiency in lowvoltage induction motors (EISA and NEMA Premium).” Yet low-voltage controls rarely enter into the debate. And that, as this article intends to show, does them an injustice.

There are three main ways in which low-voltage controls can contribute to an increase in energy efficiency:

- • By enabling the acquisition of measured energy values

- • By helping reduce intrinsic power losses

- • By providing an optimum drive solution

For machine manufacturers or operators, each one of these means a considerable improvement in energy performance figures and leads not only to the commercial benefits associated with a positive energy balance, but also to better eco credentials – a factor that is becoming increasingly important nowadays.

Acquisition of measured energy values

The first of the key steps toward increasing energy efficiency involves acquiring values relating to power flows. It is impossible for today’s energy management systems to perform satisfactorily unless the machines and plants associated with them are analyzed in detail. However, there is no need to install additional measuring instruments if, at the outset (during the planning stage), you incorporate a simple automation system with an integrated current measuring facility and communication interface – like the ET200SP Motor Starters. This simple automation system is able to transfer the most recent current value to the higher-level controller via PROFINET. With the SIMOCODE motor management system and control device or the SIRIUS 3RW5 soft starter, it is also possible to acquire and transfer additional measured values such as voltage and power values. Like the ET200SP Motor Starters, the M200D motor starter (IP65- rated), provides current values in the standard format of the PROFIenergy profile. This makes integration into energy management systems (like the SIMATIC Energy Suite in TIA Portal) even easier. The measured values of the actuators – which also serve as sensors in this case – can be dragged and dropped into the visualization system for the energy data.

The option of evaluating and analyzing measured current values allows energy management systems to assess the current situation and shut down individual loads or load groups if necessary.

For example, when it comes to energy monitoring, especially for the automotive industry, SIMOCODE, a solid state overload relay protective & motor management system all in one, helps to not only control, but monitor manufacturers’ energy. SIMOCODE motor management system provides manufacturers with diagnostics capabilities for full voltage motor applications and monitoring capabilities using it’s current & voltage measuring module. SIMOCODE can detect conditions such as a fault and modify the system to tweak other functions prior to shutting itself off (whereas other systems would automatically shut off right away), in order to protect the motors.

This makes it easy for consumers to monitor the quarter-hour values that are often used by power supply companies for billing purposes, thus enabling them to keep bills as low as possible.

Reducing power losses

Each device installed in a control cabinet produces power losses to a greater or lesser extent. For example, devices with integrated power electronics (i.e. soft starters) are burdened with higher power losses than contacting power contactors because of their system configuration. Power losses for VFDs (Variable Frequency Drives) are even more significant.

Heat is a telltale sign of these losses. In some applications, it is necessary to install high-maintenance fans; others, meanwhile, use air conditioning equipment that consumes additional energy. In view of this, the aim should be to create a drive solution that is as straightforward as possible. For more information on this, see the “Optimum drive solution” section below.

If a soft starter solution is the answer, then using the modern series of the SIRIUS 3RW5, will make it considerably more economical, as these feature hybrid switching technology including bypass contacts which jumper the power semiconductors after the run-up stage and thus enable the resulting heat losses to be kept to a minimum. Siemens SIRIUS soft starters are all equipped with this state-of-the-art technology as standard and reduce power loss by 92%.

It is easy to think that if you use contactors in an application, there is essentially nothing more you can do to make savings. It is true that contactors demonstrate exceptionally low power losses compared to soft starters or even VFDs, as the heat losses generated by the electromechanical contacts are very low. But there is one place where the potential for savings is still to be found: the control circuit. In fact, it may be possible to reduce the coil current and holding current in conventional AC and DC coils by up to 92% – in the Siemens SIRIUS Modular contactors – thanks to state-of-the-art control electronics, which also offer a number of other benefits:

- • Smaller power supply units needed in the control circuit due to significantly reduced locked-rotor currents and holding currents

- • Option of control with DC voltage or AC voltage

- • Wide voltage ranges, enabling less stock keeping

- • Control using cost-effective 0.5 A outputs of the controller

- • Integrated protective circuit for preventing overvoltage damage in control electronics

That explains why Siemens decided to introduce a dedicated range of contactors featuring UC (Universal Current) coils. These supplement its conventional contactors and can even be used with the lower power range of up to S3 size contactors.

Since the breakthrough of IEC-compliant fuseless motor starters, there is scarcely an application in this area that does not include circuit breakers or motor circuit breakers designed with the protection of plants, lines, and motors in mind. High pricing pressure on the market restricts these systems to using conventional electromechanical structures. These involve bimetal strips which provide protection against overload but have the drawback of heat losses. However, the most recent innovation within the SIRIUS 3RV2 range of motor starter protectors has managed to reduce these losses by up to 20% based on the use of modern materials. One of the outcomes is that it has been possible to increase the maximum current setting range from 65 A to 80 A while retaining the same device size (S2 = 55 mm width). These devices also consume less energy do the efficiency of the bi-metal materials.

The setting ranges in Siemens motor starter protectors overlap and there is, therefore, a very simple tip for saving energy.

If the user requires a circuit breaker for a 15 A motor, for example, they can use a version with a setting range of either 10-16 A or 13-20 A. Using the larger version and the low overload protection setting that comes with it could reduce intrinsic energy losses by up to an additional 40%.

Although fuseless motor starters are becoming more widespread, there are still good reasons to opt for overload relays. These include:

- • Differentiation of the signals for overload and short-circuit

- • In combination with fuses, extremely high short-circuit breaking capacity in high rated operating voltage ranges

As well as this, choosing SIRIUS 3RB3 electronic overload relays over their widely-used thermal counterparts brings additional benefits:

- • Wide setting range for the rated operational current of up to 1:10

- • Adjustable trip classes (5E, 10E, 20E, 30E) – make it also suitable for heavy starting

- • Remote reset following an overload trip is standard

With regard to energy efficiency, these devices offer exceptional power loss reductions of up to 98%. The reason for this improved performance is that the circuit breaker does not include a bimetallic trip. Particularly when it comes to compact structures, reduction in intrinsic heat buildup allows for a much simpler air conditioning setup in the control cabinet.

The SIRIUS 3RA6 compact starter represents an entirely new class of energy-efficient motor control. It is a compact combination of a circuit breaker, contactor, and solid-state overload relay in a single enclosure. By combining the benefits listed earlier in this article in a single device, intrinsic power loss savings of up to 80% can be achieved compared with conventional motor starters.

Consistent uses of energy-efficient motor controls switchgear allows significant reductions in the intrinsic losses of the devices and means fewer heat dissipation measures are required in the control cabinet. This is a significant advantage which benefits both energy costs and plant availability.

Optimum drive solution

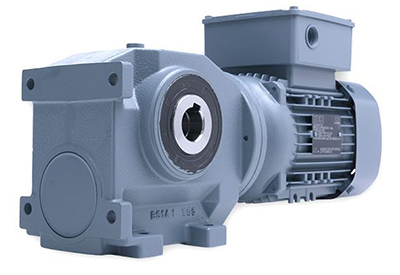

Three-phase asynchronous motors are the brawn of a machine and can be operated in a whole range of different ways. While VFDs are best suited to closed-loop speed control, soft starters specialize in regulating current and torque during start-up and runout. In combination with contactor-based motor starters and load feeders, soft starters are cost-optimized for long operating periods at the rated speed of the motors.

In applications like these, it is also a good idea to utilize NEMA Premium efficiency motors that offer a particularly low level of current consumption during operation and, therefore, bring additional benefits in terms of the energy balance. In this configuration, the products are compliant with the European Directive relating to IE3 / IE4.

As more functions mean more power losses in devices, it pays to select a drive solution with the simplest possible design. On the one hand, this involves optimum sizing for the motor power to prevent the introduction of high losses caused by oversized motors. After all, having to adapt an oversized motor to lower requirements retrospectively by using a VFD cannot be the right approach. On the other hand, it involves choosing simple methods of regulation: As always, the motor that consumes the least amount of energy is one that is not running. With pumps, fans or compressors, for example, combining a cascade VFD and controls (a process often referred to as staging) is a good way of exploiting additional potential for savings. While the VFD satisfies the requirements of the variable element of the application, the motor control covers the plant’s basic load requirements. This allows you to get the best out of both drive systems – a user-friendly control concept on the one hand and low intrinsic energy losses with the same high level of efficiency on the other.

The Siemens SIRIUS family of energy efficient products include:

SIRIUS Control

- • 3RV2 Motor Starter Protectors

- • 3RB3 Electronic Overload Relays

- • 3RT2 Contactors

SIRIUS Hybrid

- • 3RM1 Motor Starter

- • ET200SP Motor Starter

- • ET200pro IP65 Motor Starter

- • M200D IP65 Stand-alone Motor Starter

- • 3RW Soft Starter

SIRIUS Monitor with communications

- • SIMOCODE 3UF7 Motor Management System

- • 3RB24 Electronic Overload with IO-Link

- • 3RR24 Monitoring Relay with IO-Link