VFD Maintenance Tips: Restarting Your Electrical Equipment after a Long Shutdown

April 15 2025 What Are SCARA Robots? SCARA (Selective Compliance Assembly Robot Arm) robots feature a unique design with rigid vertical movement and compliant horizontal movement. This configuration resembles a human arm with shoulders and elbows that move horizontally while the wrist moves vertically. SCARA robots typically offer: Key Advantages in Manufacturing Speed and Throughput SCARA robots…

Omron’s partnership with AVEVA Edge makes machine visualization easier than ever. Although this solution is designed to work well across all industries regardless of platform, some platforms work even better – particularly the Omron NY Series Industrial PC or NY ICP for short.

June 18, 2024 In today’s fast-paced and demanding industrial environments, ensuring workplace safety and operational efficiency is paramount. However, customers often face a range of challenges that hinder their productivity and increase costs. Enter the OS33C Safety Scanner, a revolutionary solution that addresses these issues head-on, making workplaces safer and more efficient than ever before….

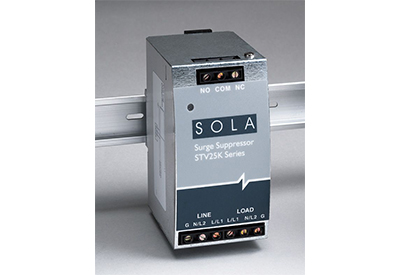

A decrease in machine availability due to power quality issues disturbs the natural flow of manufacturing, leading to lost productivity, increased maintenance requirements and eroded customer trust. Machine downtime is the single largest source of lost production, typically accounting for almost 5 percent of factory losses—although many manufacturers lose more.

With more than one million square feet of exhibit and meeting space, the LEED Platinum-certified Enercare Centre at Exhibition Place in Toronto, Ontario, is the ninth-largest convention centre in North America. Located on the shores of Lake Ontario, the convection centre experiences the extreme weather that the Great Lakes region is known for – with temperatures ranging from -31°C (-24°F) to 40°C (105°F).

In today’s industrial manufacturing space, it’s never one thing. Processes are connected, workflows are unified, and decisions in one arena have ripple effects that can impact an entire industrial ecosystem. No one knows this better than systems integrators, who are tasked with coming up with new and better industrial automation solutions every day.

Weidmüller’s scalable engineering software, u-control 2000, adapts individually to your requirements. And, the u-control is powerful, compact and fully compatible with Weidmüller’s I/O system u-remote. This article looks at what makes u-control the heart of your automation.

Programmable logic controllers (PLCs) are one of the main components of any automated system. A typical control system has inputs, outputs, controllers (i.e., PLCs), and some type of human interaction with the system, a human machine interface (HMI), for example.

April 15, 2025 By Tiffany Moore Organizations are under more pressure than ever to improve sustainability metrics. How can you help them succeed — and win more business in the process? Building motor control systems with more sustainable parts is one piece of the puzzle. Control panel builders, system integrators, and design firms have an… Read More…

April 15, 2025 By Damien Herwegh Sophia, a dedicated electrical engineer in a large industrial complex, has been tasked with installing a drive system where the motor is located hundreds of meters away from the control room. Like many engineers before her, she considers the usual question: Should I place the drive in the electrical… Read More…

This project is funded [in part] by the Government of Canada.

Ce projet est financé [en partie] par le gouvernement du Canada.