Understanding the Differences Between Machine Guard and Perimeter Guard Light Curtains

July 27, 2020

Safety light curtains are a relatively hassle-free, cost-effective way to protect your team from hazardous machine motion. Compared with hard guarding, such as a fence or lexan barrier, light curtains have a lower cost of installation and maintenance. They also simplify machine maintenance by making it unnecessary to remove any physical barriers that block access.

Light curtains fall into two major categories: machine guard and perimeter guard. Machine guard light curtains cover a specific portion of the machine that happens to be particularly hazardous. They’re further categorized by their “resolution” – that is, whether they can protect an arm, a hand, or even something as small as a finger.

Perimeter guard light curtains, on the other hand, cover machine area access. Since they prevent a person from even reaching the machine, resolution is very wide. It’s important to determine where the curtain must be mounted to prevent a person from reaching the danger zone before motion can stop. This requires a machine stop time measurement.

Often-overlooked advantages of perimeter guard light curtains

Some manufacturers have a tendency to select high-resolution machine guard light curtains when there might not be a need for this amount of protection. If there’s typically no reason to frequently access a machine, then a perimeter guard might be a better option. On the off chance that someone walks up to the machine, the perimeter guard will quickly shut it down.

Perimeter guard light curtains are less expensive than machine guard light curtains because they require fewer LEDs. This is because they’re designed to detect a whole person passing through, rather than a smaller body part like a hand or finger. They also ensure protection across a much wider area.

When to use a machine guard light curtain

If a particular machine needs to be accessed frequently, machine guard light curtains might be the better option for protecting operators from specific areas of the machine with hazardous motion. It would be impractical to shut the machine down each time someone needs to walk up to it when there’s a way to detect an arm or hand entering the specific danger zone.

The Omron light curtain advantage

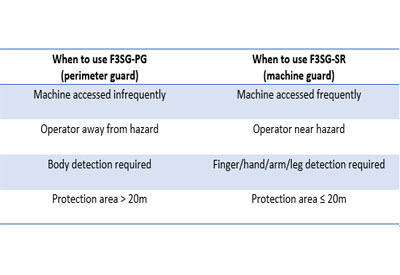

Whichever option you require for your machine, Omron has a flexible and user-friendly light curtain solution to meet your needs. The new additions to the F3SG family include both a perimeter guard version (the F3SG-PG) and a machine guard version (the F3SG-SR) that includes finger, arm, hand and leg protection options.

Below is a table indicating when to choose the F3SG-PG versus the F3SG-SR.

All Omron light curtains use the same cabling and brackets, so if something changes in your light curtain needs, all you need to change is the curtain itself. Everything else works the same. Both the machine guard and perimeter guard versions feature three-color beam indicators that let you know whether the light curtain has been aligned properly.

To learn more about how Omron can help you with your safety light curtain needs, click here.