Ultra-Low Harmonic Drives for Increased Efficiency and Reliability of Processes and Systems

Ultra-Low Harmonic Drives for Increased Efficiency and Reliability of Processes and Systems

June 3, 2022

By Krystie Johnston

Variable speed drives can save substantial amounts of energy by adjusting motor speed to the application need. But it is crucial to evaluate the effect of VSDs on the power system before making the final choice, because some variable speed technologies can have an adverse impact on the power quality in the network, resulting in lower system efficiency and reliability, and higher project costs.

Limitations on the electrical power system make it important for the customer to reduce harmonics in their system to avoid voltage disruption and overheating of the mechanical and electrical components within the industrial plant. There are several ways to reduce harmonics, each with its costs and benefits. Drives & Control Solutions had the opportunity to hear from Martin Royer, local Division Manager for System Drives at ABB Canada, to discuss why Ultra-Low Harmonic Drives (ULH) with an active front-end are a preferred choice for businesses and utility owners.

What Are Electrical Harmonics and Why Do They Matter?

Electrical equipment runs most efficiently and reliably when it is supplied by a clean, disturbance-free electrical power. However, often power networks are subjected to continuous or transient electromagnetic disturbances due to multiple reasons. The most frequently seen continuous disturbances present in almost any network are often harmonics, which can have a significant effect not only on power network efficiency, but also reliability.

Harmonic currents are created by non-linear loads connected to the power distribution system. Harmonic distortion is a form of pollution in the electric plant that can cause problems if the voltage distribution caused by harmonic currents increases above certain limits. Common non-linear loads include motor starters, variable speed drives, computers and other electronic devices, electronic lighting, welding supplies and uninterrupted power supplies.

The effects of harmonics can include overheating of transformers, cables, motors, generators, and capacitors connected to the same power supply with the devices generating the harmonics. Electronic displays and lighting may flicker, circuit breakers may trip, computers may fail, and metering may give false readings.

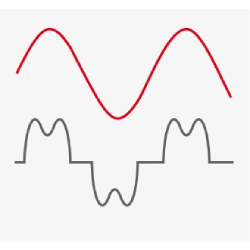

In an ideal world, electrical supply has a pure sine waveform (top). However, in reality, it is often distorted (bottom) due to unwanted harmonics.

Variable Speed Drives and The Importance of Their Harmonic Performance

Variable speed drives help to save a tremendous amount of energy in processes with varying loads, and they do this by adjusting application motor speed to the exact process need. However, their possible effect on the power network and connected equipment should still be considered.

Active Front End Drive Technology and Its Benefits Over Other Solutions

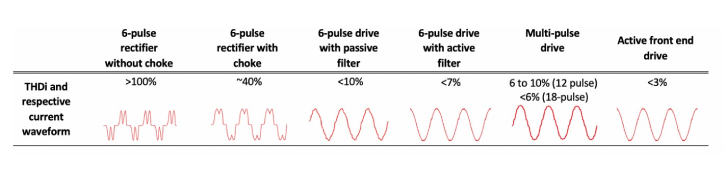

There are many drives technologies present on the market today, with very different power quality performance. When a low harmonic content is critical for an application, the drives for the project should be selected carefully to avoid costly additional components like harmonic filters and to prevent any negative effects on the process’s reliability.

Harmonic content at nominal load with different solutions

Overcome The Challenges of Harmonics with ABB’s Ultra-Low Harmonic Drives

- •ABB ultra-low harmonic drives

- •Keep the electrical network clean

- •Reduce the risk of disturbances

- •Prevent damage to other equipment

- •Prevent interference with communications equipment

- •Reduce the installation footprint

- •Reduce the total cost of ownership

Efficient Energy Utilization and Benefits

Ultra-low harmonic drives achieve a unity power factor, indicating that electrical energy is being used efficiently. The drive offers the possibility for network power factor correction to compensate for the low power factors of equipment connected to the same network. It can help to avoid penalty charges set by electrical utilities for poor power factors. Lower harmonics and full motor voltage mean reduced system losses and better overall system efficiency.

ABB’s family of ultra-low harmonic industrial ACS880, HVAC ACH580 and water ACQ580 drives is based on active front end technology with DC bus capacitors

For All Industries and Applications

ABB’s ACS880-37 Ultra-Low Harmonic drives (ULH) are customized to meet the precise needs of most industries, such as the oil and gas, chemical, pulp and paper, food and beverage, rubber and plastics, marine, metals, and mining industries. Industry specific ultra-low harmonic drives ACH580 and ACQ580 are available for the HVAC and water industries. To learn more about these products, click here

Standards for Harmonic Limits

Limits for harmonic currents are given in several national and international standards. Additionally, many transmission and distribution system operators have issued requirements especially for high power equipment connected directly to medium or high-power grids. Certain industries have even set factory-specific regulations. The most important standards are the ones issued by International Electrotechnical Commission (IEC). Another important publisher is the Institute of Electrical and Electronics Engineers (IEEE) located in the USA. IEEE standards are often required outside the USA as well. The most common international and national standards that set limits on harmonics are described in detail in Guide to Harmonics with AC Drives. This article focus is on IEEE 519, which outlines the IEEE recommended practices and requirements for harmonic control in electrical power systems.

Conclusions

For systems which require minimal harmonic content as is typical in mission critical facilities, variable speed drives based on active front end technology with DC bus capacitors, like ABB’s ultra-low harmonic drives, are the optimal solution. They ensure not only process efficiency itself, but also power network efficiency, while contributing to controlled process reliability. The substantial reduction in capital and operating costs from ultra-low harmonic drives with an active front end makes them a preferred choice for business and utility owners.

To learn more about ABB’s Ultra Low Harmonic Drives and Solutions, download the Ultra-Low Harmoninc and Regenerative Drives White Paper by clicking here or visit their website by clicking here