Three Ways a Digital Twin Can Give OEMs a Competitive Edge

June 2, 2020

By Matthew Masarik, Marketing Manager, Design Software, Rockwell Automation

Gartner predicts that by 2022, or perhaps sooner, more than two-thirds of companies that have implemented IoT projects will have launched at least one digital twin in production.

That’s not surprising. A digital twin, which is a living digital replica of a physical asset, transforms what’s possible in industrial operations. It can provide insights into the design, performance and health of a machine. And it can change how people work by transporting them into a virtual world.

If you’re a machine builder, the nearly unlimited uses of a digital twin can make its value difficult to grasp. So, let’s look at three key competitive advantages that the technology can unleash in your business.

1. A Better Way to Design and Sell Machines

You can use a digital twin to design, test and prove your machines digitally, before you build anything. This can help you create higher-caliber, lower-risk machines and get them to market faster.

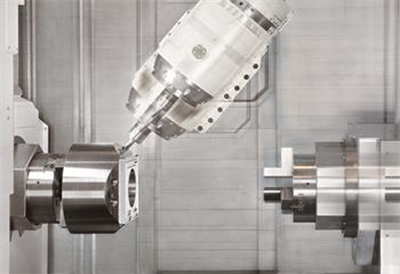

Using simulation software, you can apply physics to your machine’s CAD model and connect it to your controls program to bring the model to life. Then, you can see how your machine runs and interacts with both people and other machines in a virtual environment. If you want to tweak your machine, you don’t need to buy parts or build a physical prototype. Instead, you make the changes in your model, which is faster and more flexible.

You can also use a digital twin to improve how you sell a machine. KUKA Systems Group, for example, uses digital twin software to help sell its flexible automatic production systems.

If the company develops a sprawling conveyor system, for instance, it can use a moving 3D simulation to show cases moving through the system. The digital demonstration can erase any doubt in a customer’s mind about how such a complex system will run. And as the company has discovered, it can also turn sales presentations into design reviews.

2. Faster, More Consistent Commissioning

When a machine design and the operating logic of its control system come together for the first time, there’s a risk they won’t be aligned. This can lead to last-minute design changes that are not only costly but can cause you to miss your customer’s start-up deadline.

You can avoid these surprises by using a digital twin to virtually commission your machine.

By creating a dynamic digital twin of both your machine design and the real operational logic of its control system, you can do controls testing before you have a physical machine.

This can help you identify problems like controls integration or line sequencing issues early in the design phase – rather than at the 11th hour as a start-up deadline nears. It can help you verify and demonstrate the operation of your machine and its controller before you commit resources to them.

3. Optimized Operations for Customer

When you pass a digital twin of your machine to a customer, you can help them optimize production and reduce downtime in several ways.

For starters, your customer can use the digital twin to train operators virtually, before your machine arrives. This can help workers build competency sooner. And it can help them prepare them for a wider range of incidents than real-world training, because virtual training allows you to simulate faults and extreme conditions that may be difficult to recreate physically.

During production, a digital twin can simulate operations, which can help workers explore opportunities for improvement or try out changes before making them. Operators can virtually experiment with production scheduling and sequencing, for example, to optimize product mixes and volumes. And they can test and validate new products to avoid problems like downstream bottlenecks.

Finally, a digital twin can help maintenance teams reduce downtime in new ways. If there’s a stoppage, technicians can see digital diagnostics overlaid on a physical machine in an augmented reality (AR) environment to more quickly troubleshoot the problem. They can also access digital work instructions or 3D animations in the AR environment to more quickly repair the machine.

A digital twin can make you more competitive by improving how people work and moving projects into a dynamic digital environment.