The digital transformation of Linear Motion Technology

March 18, 2019

By: Dr. Ulf Lehmann

Head of Business Unit Linear Motion Technology at Bosch Rexroth AG:

Machine manufacturers are currently experiencing a profound generation change. All engineers and designers below their mid-thirties have grown up with cell phones and the Internet. Digital technology plays a very strong role in their private lives, and they have completely different solution strategies than previous generations.

This is also increasingly affecting the professional use of technology. The new generation seeks concrete solutions for automation processes and functions rather than components and systems. Their justified expectation is that all applications, information channels and platforms should be as easy to use as those in private life. This also applies to the selection, dimensioning and configuration of Linear Motion Technology. And Rexroth is meeting these expectations for a growing number of automation tasks.

Digital engineering tools and configurators guide users logically through all the engineering steps. The future will see further simplifications in this area too, including interactive websites with chat facilities. To complete their designs, the users will work directly with the digital twins of the components and systems they configure.

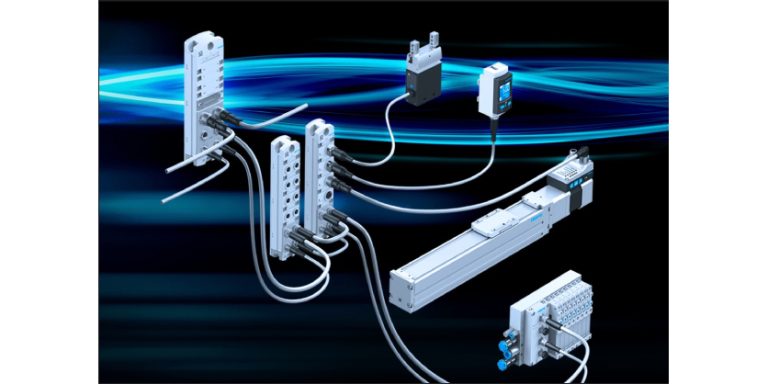

The manufacturers of Linear Motion Technology components and systems face a dual challenge. For one thing, mechanical performance data remains the decisive criterion for the use of components. Bosch Rexroth is continuing to expand its portfolio in this area. At the same time, the company is developing additional solutions with greater functional integration and complete connectivity solutions for automation processes and functions on this basis.

For example, components and systems from Rexroth Linear Motion Technology will, in future, have a digital name plate. This will make the start-up easier and, if servicing is required, will provide all the relevant data. Ball Screw Assemblies with intelligent sensors are about to be launched onto the market. They record status data such as temperature and vibrations. An integrated decentralized intelligence uses algorithms to derive the state of wear from this data, thus enabling condition-monitored maintenance of linear axes. Another approach is the design of complete mechatronic modules for functions, such as joining and pressing. One example for this is the new Smart Press Kit from Rexroth, a Plug & Produce solution that the user only needs to parameterize. Like all new systems, it can be connected via open interfaces.

The digital transformation will continue. The Bosch Group is increasingly becoming a leading Internet of Things (IoT) company, and engineers and researchers from different departments are working together on many advance development projects. Our Linear Motion Technology benefits from the unique know-how within the Bosch Group, whether in the area of sensor systems or of software programming.

The new generation of design engineers has high expectations – and Rexroth’s Linear Motion Technology increasingly succeeds in meeting them. It is easy to use throughout the entire engineering process, it integrates more and more functions for predictive maintenance and process optimization, and its digital twins will fit seamlessly into virtual designs and value streams in the future.