Special Delivery: How Collaboration Has Overcome Global Supply Chain Issues

September 9, 2022

The strain placed on global supply chains this year continues to make headline news, from semiconductor shortages to labour and equipment availability, all exacerbated by geopolitical uncertainty.

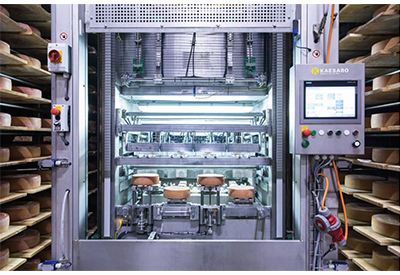

One cobot is typically comprised of around 600 different parts, sourced from more than 100 separate suppliers. Any one of those not being available would lead to delays in completing production and delivering a finished arm to customers.

In a challenging landscape, Universal Robots has seen significant growth in production while fulfilling its production plan. Through this time, the company managed to deliver cobots with typical lead times, despite global shortages of key components and ongoing delivery issues. Compare this to the market average, where it has sometimes been taking four months for delivery, and it is especially impressive.

You might wonder what the recipe for success is? The answer is simple: collaboration.

Committing To Relationships

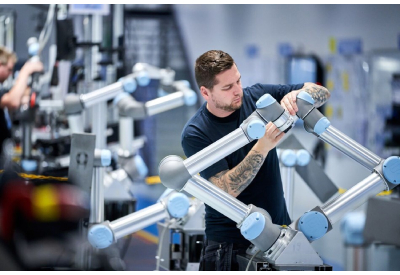

The production team at Universal Robots is 150 people strong and all of them are involved in getting a cobot made on time. Many of these people are specifically tasked with overcoming supply chain issues – in other words, sourcing, dual sourcing and even triple sourcing components.

What has been essential is building strong relationships with suppliers to ensure, even when disruption hits, there are always solutions to avoid any delays. This has included team members travelling to component suppliers earlier in the year to oversee the finalising and shipping of crucial components.

“Collaboration and communication have been key, with the team speaking to primary suppliers on at least a daily basis,” said Vice President for Operations and Supply Chain, Anders Lassen, adding “The emphasis is on keeping everyone aligned to the shared goal – namely, the timely delivery of cobots to our customers.”

Remaining Agile

This collective effort aligned with outside-the-box thinking to find solutions to problems. At Universal Robots, there is an inherent embrace of innovation, with a disruptor mindset that allows for an agile and quickly adaptive approach.

This culture of trust and collaboration also relies heavily on close ties with the R&D teams as products sometimes need to be altered based on the components that are available, without compromising on the end quality. Teamwork and commitment have not been limited to the production team; the R&D department has worked tirelessly to support the collective effort and ensure that products continue to be developed and delivered.

Contingency Plans

A further time-saving tactic has been getting contingency plans approved as hypotheticals, meaning no further sign off is required if they were ultimately needed.

Sometimes these contingencies come at extra cost as market conditions and supply-demand dynamics increase prices and alternative solutions, such as buying parts from brokers, can be expensive. On-time delivery of cobots to customers has taken precedence over profit margins and remains an area the company sees as giving it a clear competitive advantage in the market.

Additionally, in a fight for high-demand items, Universal Robots has been able to draw on the influence of parent company Teradyne to help with sourcing.

Centralizing Operations

While selling to customers worldwide and being prepared to source parts from global suppliers, Universal Robots remains a resolutely Danish proposition, with all production taking place at its Odense headquarters. This allows the company to retain a high level of quality control over its end products but brings inevitable complexities in supply chains. For key components, there are suppliers in Europe, Asia and the Americas, with the quickest and most cost-effective option chosen based on demand. This has built resilience for when, for example, there is increased difficulty getting deliveries from China – the team knows what its alternatives are and can identify these issues well in advance.

Having a wide a variety of options open limits the impact of wholesale difficulties hitting an entire region.

Delivering For Customers

Timely delivery of robots is a high priority for customers, particularly in a business environment characterized by fluctuating demand and uncertainty. Short delivery times mean companies can transform their operations quickly and see results within weeks rather than months.

“Commitment to every customer’s success is one of the core company values at Universal Robots” said Mathias Wiklund, UR’s Chief Commercial Officer. “Our customers often turn to UR to tackle labor shortages and to make their businesses more productive. Our ability to continue to deliver cobots within a short timeframe, despite unprecedented complications, continues to set Universal Robots apart from its competition.”

The Year Ahead

The reality is that difficulties with global supply chains are likely to continue for another year, though the Universal Robots approach and process will stand the company in good stead to keep delivery time as low as possible.

At one stage in Q1 of 2022, as many as 30 components were at “critical” status – meaning there were urgent issues in sourcing them. This is now down to just eight, though any one part can threaten the ability to keep production running to schedule.

Universal Robots is robust, with a can-do attitude and a team that constantly thinks of alternatives. To have increased orders this year while delivering cobots in around a quarter of the time of competitors, despite unprecedented global sourcing issues, is true testament to an extraordinary ongoing collaboration.