Revolutionizing EV SMT Assembly: Enhancing Quality and Efficiency with Advanced CT X-Ray Inspection

April 30, 2024

In the dynamic realm of electric vehicle (EV) manufacturing, ensuring the utmost quality and reliability of circuit boards is of paramount importance. Omron, a pioneering force in automaton technology, has developed the VT-X850, an innovative CT X_Ray inspection system tailored specifically for EV SMT (surface mount technology) assembly

This state-of-the-art machine offers a range of impactful features that address the distinctive challenges faced by EV manufacturers, ultimately elevating both the quality and efficiency of the production process.

Handling Heavy and Large Samples with Ease

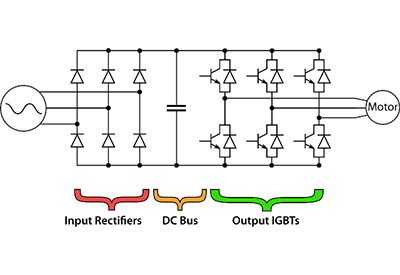

One of the key challenges in EV SMT assembly is handling heavy and large samples, such as Insulated Gate Bipolar Transistors (IGBTs) and eAXLE devices. The VT-X850 is equipped with larger loading doors and stronger conveyors, allowing for seamless inspection of these challenging components. This increased sample capacity allows EV manufacturers to thoroughly inspect heavy and thick samples, ensuring the reliability and durability of their products.

High-Powered X-Ray Imaging for Challenging Devices

EV eAxle assemblies, which include IGBTs, electric motors, transmission, and power modules, often feature heavy shielding or enclosures that can be challenging to inspect with traditional X-Ray systems. The VT-X850 overcomes this challenge with its high-powered X-Ray tube, capable of 160kV. When paired with Omron’s fast CT technology, the system is capable of producing images with excellent contrast and minimal interference, making it easier to identify defects in devices with thick shielding or enclosures. EV manufacturers can now have confidence in the quality of their solder joints, even in the most challenging applications.

Unparalleled Inspection Accuracy with True 3D CT Imaging

To ensure the highest quality solder joints, EV manufacturers must be able to detect even the most subtle features. The VT-X850 utilizes true 3D CT X-Ray technology, capturing over 300 cross-section images of each solder joint. This comprehensive analysis allows for the identification of challenging defects such as Head-in-Pillow features, poor barrel fill, and excessive voiding. With the VT-X850, EV manufacturers can achieve complete inspection accuracy, to ensure that no defect escapes their scrutiny.

Streamlined Production Process with High-Speed Automation

Traditional manual 2D X-Ray machines used in solder joint inspection often slow down the production line and require significant human interaction. The VT-X850, on the other hand, is a high-speed 3D CT X-Ray inspection system designed to seamlessly integrate into existing SMT production lines. With conveyors for PCB handling and support for industry protocols, it can communicate effortlessly with other production equipment. This automation reduces the inspection workload for engineers and ensures faster and more efficient production processes.

Eliminating Subjectivity and Improving Repeatability

Subjective human judgment in solder joint inspection can lead to inconsistent results and make it impossible to obtain real measurements. Omron’s Automated Inspection Systems, including the VT-X850, utilize automated algorithms to perform solder inspections. This approach offers improved repeatability when compared to the manual alternative, which ultimately reduces the chance for errors and inconsistencies. EV manufacturers can now rely on accurate and repeatable measurementsm for EV SMT, ensuring the highest quality standards for their products.

Minimizing Production Downtime with Maintenance-Free Technology

Traditional “open tube” X-Ray sources require frequent maintenance and can cause significant downtime for production lines. The VT-X850, however, features a “closed-tube” X-Ray source that requires zero maintenance for over a year. When the tube reaches the end of its lifespan, it can be easily replaced with a new one, minimizing interruptions to the production process. This maintenance-free technology ensures that EV manufacturers can maximize their productivity and minimize costly downtime.

Omron’s VT-X850 CT X-Ray inspection system revolutionizes EV SMT assembly with advanced solutions. It handles heavy samples, offers high-powered X-Ray and true 3D CT imaging, high-speed automation, eliminates subjectivity, and requires no maintenance. This enhances quality and efficiency, giving EV manufacturers confidence in their circuit boards and advancing the electric vehicle industry.

More Information

VT-X850 CT AXI Machine for EV SMT

Related Story

Sealing and Material Coating in EV Manufacturing – How Omron’s Technologies Refine Quality

When it comes to electric vehicle or EV manufacturing assembly, meeting downstream customer demand for vehicle delivery while maintaining quality expected by downstream customers in the lite vehicle domain is the name of the game. With Omron’s EV sub assembly services, you can streamline your production and improve the quality of your EV parts. The source of this capabilities is the inherent automation flexibility built into Omron’s all-in-one automation platform which bridges the production gap between brownfield facilities which are starting EV production and new EV greenfield facilities.