PROFIBUS vs. PROFINET: Path to the Future

October 31, 2023

Distinguishing PROFIBUS from PROFINET

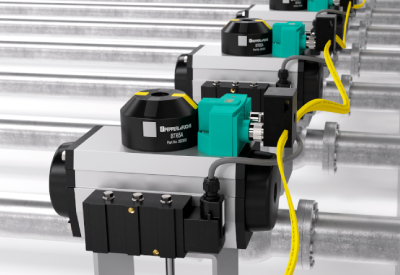

PROFIBUS, established in 1989, is a veteran serial Fieldbus, while PROFINET represents the Industrial Ethernet protocol, a future-proof solution. Both standards emerge from the same organization, PROFIBUS and PROFINET International, yet their characteristics markedly differ.

History and Future Direction

Introduced in 1989, PROFIBUS rapidly expanded throughout the 1990s as a pioneer in fieldbus technology. However, the monumental shift towards Industrial Ethernet took place around 2000. In response, PROFINET was developed to meet the new demands. Commencing in the early 2000s, it has consistently evolved to suit the needs of the modern industry.

Technical Disparities

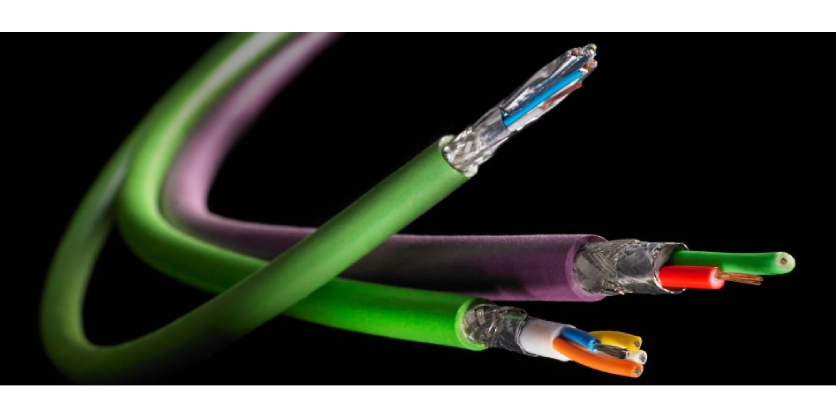

PROFIBUS networks (based on RS-485) can achieve speeds up to 12 Mbit/s, though most operate at 1.5 Mbit/s. Telegram size can extend to 244 bytes, with an address space limited to 126 devices per network. PROFINET networks attain speeds of 100 Mbit/s or even 1 Gbit/s and beyond. Telegram size can reach 1440 bytes, and there are no restrictions on address space. While the specification doesn’t limit address space, individual controllers will have limitations based on their processors and memory.

Transitioning from RS-485 to Ethernet signifies a move toward more advanced technology. Since PROFINET exclusively utilizes standard Ethernet, it’s future-proof; as commercial Ethernet evolves, it can capitalize on these advancements. When PROFINET was introduced, 100 Mbit/s Ethernet was the standard. Presently, it operates seamlessly on today’s Gigabit Ethernet (and higher). The shift to Ethernet-based technology allows for greater bandwidth, larger message sizes, and unlimited address space.

Data Transmission

Master/slave to provider/consumer – PROFIBUS employs a master/slave model, while PROFINET utilizes a provider/consumer scheme. In PROFINET, both controllers and devices are active consumers and providers of data. This flexibility is key to establishing efficient two-way communications.

Ports and Future Focus

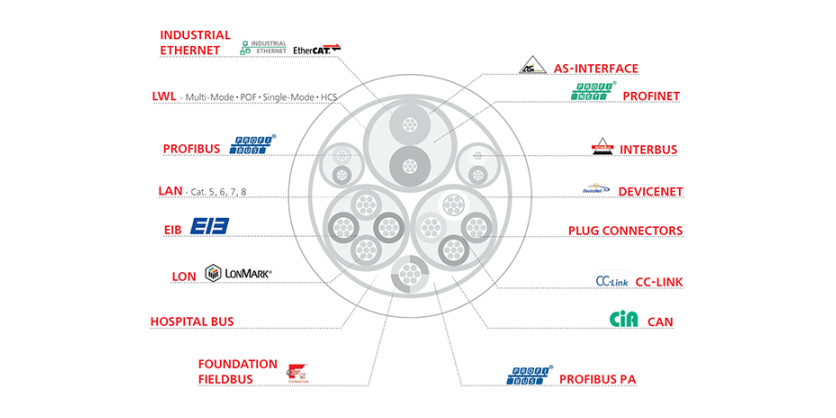

Companies have devised gateways that translate to PROFIBUS from other networks. PROFINET has gone a step further by defining proxies in its own specification. Proxies resemble gateways in the sense that they translate one network to another, yet unlike gateways, they are defined by an open standard. It offers proxies for PROFIBUS DP, PROFIBUS PA, AS-i, IO-Link, DeviceNet, Foundation Fieldbus, CANopen, Modbus, HART, and more. For instance, IO-Link and AS-i proxies enable communication with smart devices lacking an Ethernet port. When to use one over the other? Brownfield – use PROFIBUS. Greenfield – use it. A brownfield site already equipped with PROFIBUS can continue adding PROFIBUS nodes. However, if you need to incorporate Ethernet functionality, considering a smaller PROFINET project could be worthwhile.

Applicability to Your Business

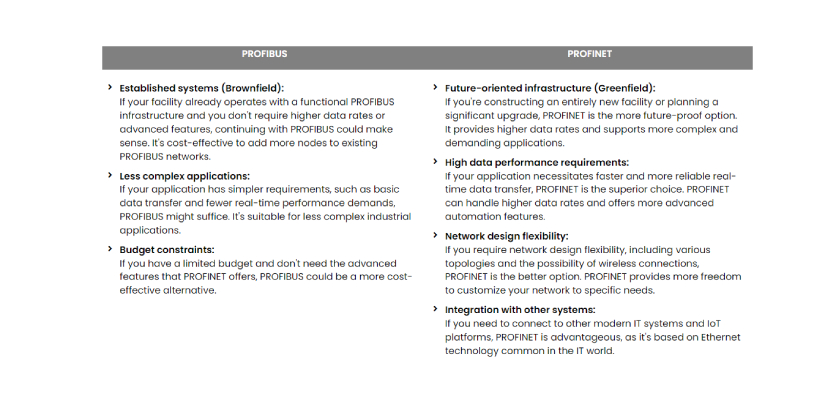

PROFIBUS and PROFINET boast distinct characteristics and benefits. The choice between them hinges on your facility’s current status and future aspirations. Choosing between both relies on multiple factors, including your existing system, specific needs, and future goals. Here are some general guidelines for considering each technology:

In conclusion, if you have an established PROFIBUS environment and simpler needs, PROFIBUS could be a suitable solution. If you’re aiming for a modern and future-proof infrastructure with high-performance requirements, complex applications, and the need for flexibility, PROFINET is the better choice.

A journey to the future begins here – the choice is yours!

More Information

To see more of HELUKABEL’s industrial data, network and bus cable solutions, click here .

Related Story

Put to the Ultimate Test – Part 1: Torsion Tests by HELUKABEL

Cables and wires in industrial robots and other moving machine parts are often required to withstand extreme stresses caused by torsion. Constant repetitive movements put materials under considerable strain. At the same time, operators expect components to function perfectly and reliably throughout their entire service life to avoid disruptions, outages and safety hazards.