Partnering Together for a Circular Economy: ABB Large Motors and Generators Sweden and Stena Recycling

May 16, 2022

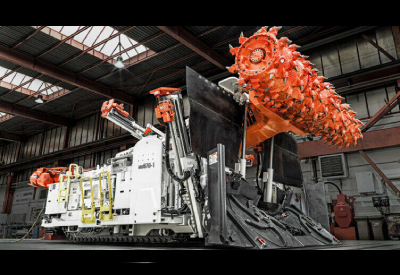

Did you know that an ABB large motor or generator is 98% recyclable, with the remaining 2% of materials available to be incinerated for heat recovery? ABB Large Motors and Generators in Sweden have recently joined forces with Stena Recycling to offer our customers an opportunity to recycle their old machines. The deal ensures that end-of-life motors/generators are recycled in an environmentally friendly way and the metals are reused in new products made in Europe.

ABB’s Motion business area focuses strongly on energy efficiency and finding ways to reduce energy use and environmental impact where it is the greatest – in the use phase of the customer. In addition to this use phase, life-cycle analysis of the machines has shown that the two major components: the rotor and stator are those that contribute the greatest environmental impact through, above all, the production of raw materials and processing. Recycling these components together with the entire machine could contribute to a major reduction in the environmental impact. Therefore, ABB has now started to focus on the end-of-life management of the large machines and sees that circular material flows are the future.

The Large Motors and Generators division in Sweden has been instrumental in expanding a concept with Stena Recycling, similar to the one that exists for small motors, to now also cover all large motors and generators over 10 tonnes. The concept means that old motors are recycled in conjunction with Stena Recycling in an efficient and environmentally friendly way, where the old motors are replaced with new and more energy-efficient motors.

The big differences between the previous concept for small motors and generators and the new one, for large motors and generators, is of course the size of the machines, the metal composition in the machines and how these are transported from a customer’s site to Stena recycling. In addition to the transportation, ABB Sweden can now offer customers a recycling compensation and environmental report in collaboration with Stena Recycling, when purchasing new products from ABB.

{youtube}jWWWz0RuWOk{/youtube}

Why is ABB Large Motors and Generators in collaboration with Stena Recycling?

We feel that together with our customers, we can contribute to a reduced environmental impact.

– We want to prevent unsafe machines from ending up on the secondary market.

– We also want to take responsibility for our products after they have left ABB’s gates.

By 2030, we at ABB intend to have over 80% of our products and solutions based on this circular approach and to help our customers reduce their carbon dioxide emissions and impact on the environment.

If your company is interested in learning more about this, please contact our Sweden office: https://new.abb.com/contact/sv/form