Ontario Northland’s Remanufacturing and Repair Centre – Q&A with Lonnie Little, Director of Rail Mechanics at Ontario Northland

June 24, 2022

By Krystie Johnston

The history of rail transport in Canada is fascinating. Ontario Northland Railway (known as the Temiskaming & Northern Ontario Railway, or T&NO until 1946) began construction in 1902. At this time, it was the only railway interested in expanding beyond North Bay into the Great Clay Belt. Construction proceeded slowly but steadily, until the settlement of Cochrane was reached. In 1932, the T&NO opened another extension from Cochrane to the small settlement of Moosonee, with the intent to build a port so ocean freighters could transfer goods from James Bay.

The port never materialized, but this trackage serves the Cochrane-Moosonee Polar Bear Express train, which is the only all-season land link to the James Bay Coast. In the early 1990’s, the ONR bought 145 miles of CN trackage between Cochrane and Calstock, allowing them access to the Spruce Falls Pulp and Paper Company in Kapuskasing. Today, the ONR has 650 miles of trackage, yards, engine sheds, maintenance facilities, and diesel shops in many northern towns1.

Readers may recall taking an Ontario Northland bus or train, or using their parcel express to ship something. What might not be so well known is their remanufacturing facility with wide-reaching capabilities. Recently, the Ontario Northland Remanufacturing and Repair Centre in North Bay received $109 million in funding from the Ontario government to refurbish 56 GO Transit bi-level raid coaches. Ontario Supporting Manufacturing Jobs in North Bay is part of the government’s plan to expand service across the GO rail network and support economic development and job creation in the North.

Drives & Control Solutions had the opportunity to ask Lonnie Little, Director of Rail Mechanics at Ontario Northland, about this funding and about the Remanufacturing and Repair Centre. With over a decade of experience at Ontario Northland, he is an experienced railroad professional who knows his rail mechanics.

What refurbishments are planned for these 56 GO Transit bi-level rail coaches at the North Bay facility?

The scope of the 56 GO-Transit bi-level rail coaches remanufacturing project includes stripping the entire coach, working on the structure, upgrading parts, new seating, enhanced washrooms, electrical components, as well as HVAC and door system upgrades. The coaches will appear brand new when the work is completed.

Why do you think these rail coaches are being repaired at a facility in the North?

Ontario Northland is North America’s leader for remanufacturing and refurbishment work of passenger railcars. As a manufacturer, we provide the unique perspective of also running our railway. We are known for delivering the highest quality of work, on-time, and on-budget. Furthermore, we are merely 250km down the track from Metrolinx, making delivery of the 56 bi-level GO cars seamless and quick, particularly compared to our competitors.

What is the Remanufacturing and Repair Centre? Can you provide details about what the facility has and does?

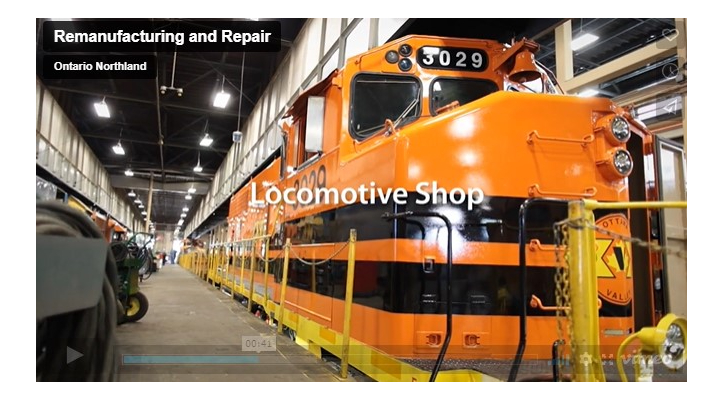

This video provides a great visual of our shop and highlights some of the work our staff is capable of.

{vimeo}https://vimeo.com/95156497{/vimeo}

Accommodating 12 to 14 locomotives at a time, the 47,735 square foot locomotive refurbishment shop has a 32-foot ceiling and two 20-foot-high doors. The shop is equipped with two 450 feet exhausted, elevated running repair tracks, a 244-foot heavy back shop repair track with a 25-ton capacity overhead crane and a 100 ton drop table for the removal of locomotive trucks. The Shop specializes in EMD GP38, GP40, SD40.

The car shop is 61,050 ft and features two pits, at 105 feet and 60 feet. It houses eight station assembly lines across four lines of railway track, and it also features component rebuilding areas: full fabrication, a blacksmith, a specialized welding shop, an AAR certified air brake shop, and a truck shop.

Ontario Northland is also the home of a state of the art paint facility and a wheel shop.

Our Employees are highly skilled and experienced, including roles such as production workers, railway car mechanics, machinists, electricians, welders, production and project managers, engineering specialists, painters and many more.

What is the Locomotive Video and Voice Recorded System and what does it do?

Locomotive Video and Voice Recorded System (LVVR) is an integrated monitoring system that uses one or more cameras and microphones to collect data about in-cab operating. Specifically, the recording devices will capture the control panels and human activities inside a locomotive. This digital technology can be used to strengthen safety management systems and prevent accidents, through risk mitigation.

Ontario Northland staff began installing these units into trains in 2022. The Remanufacturing and Repair Shop is ideal for the installation of this kind of equipment given that unlike most locomotive shops, Ontario Northland also operates a railroad. Our employees have a unique perspective of how this technology will be used by employees at all levels of the organization.

We are also ideal for this kind of work because our Northern climate gives us first-hand experience of the extreme weather engineers and conductors will be working in. This gives our staff a greater understanding of the context for which this data will be collected. Furthermore, although the technology is different, the use of audio and visual technology to enhance safety has been used on our motor coaches and Polar Bear Express train for some time.

The installation of LVVR technology on all new and refurbished trains is another step in providing an exceptional safety environment for passengers and crews across Canada. Under the Railway Safety Act, LVVRs will become mandatory on all trains as of September 2, 2022. This requirement will ensure all trains will have access to the same high-quality prevention and investigation tools.

What are some examples of the criteria that the LVVR must meet?

In Canada, LVVRs must adhere to many specific requirements including technical specifications for the voice and video recording equipment, crashworthiness standards as well as access to and storage of data. For example, all video quality must be 15 frames per second, with clear visibility in all lighting with resolution high enough to view instrument displays and facial features. This is an example of the level of detail the government will be looking for while ensuring compliance.

What other controls or safeguards are in place to minimize accidents?

When examining rail safety over the past several decades, the industry has come a long way. Mechanists and technicians have created infrastructure that was unfathomable even ten years ago. Basic infrastructure such as dragging equipment detectors, which alert train crew that something is dragging or if a wheel has been derailed, have massively enhanced rail safety. Another example is hot bearing detectors, which takes the temperate differential from one axel to another, alerting the conductor and engineer if an axel has become too hot to safely operate.

We believe LVVRs will contribute to rail safety in the same way these classic pieces of infrastructure do. They will be integral in our investigations when there has been an issue, so we can continue to discuss how we can help maintain rail safety and prevent future accidents.

At Ontario Northland, we are excited to continue to install this important safety equipment in our shops. We hold ourselves to the highest standards and as Director of Rail Mechanics, I could not be prouder of my staff and their contributions to rail safety across the country.

The capabilities of the Ontario Northland Remanufacturing and Repair Centre in North Bay really are impressive. Thank you, Lonnie, for taking the time to provide these detailed answers.

To learn more about Ontario Northland, visit their website: https://www.ontarionorthland.ca/en

1. Ontario Northland: Through timber to tidewater