Noark Explains What an Industrial Control System Is

December 15, 2023

Have you ever wondered what keeps the wheels turning in those massive industrial plants? Well, here’s a little secret: it’s an Industrial Control System, or ICS for short. Although it might not be a term you hear every day, understanding what an ICS is could ignite a spark of interest in your tech-savvy soul. So, let’s dive into the world of ICS and unravel its mysteries.

Demystifying Industrial Control Systems:

An Industrial Control System (ICS) is a complex network of hardware, software, and protocols that work together to automate and manage industrial processes. Think of it as the brain behind the brawn, controlling everything from the temperature of a furnace to the speed of an assembly line. ICSs are commonly found in various sectors like manufacturing, energy, transportation, and even water treatment plants.

Components of an ICS:

An ICS typically consists of three core components:

- Supervisory Control and Data Acquisition (SCADA) Systems: These are responsible for gathering data from sensors and devices, monitoring the process, and providing real-time insights to operators or engineers. SCADA systems are like the eyes and ears of the ICS.

- Programmable Logic Controllers (PLCs): PLCs are the workhorses of an ICS. They receive data from sensors, make decisions based on predefined logic, and control the actuators to perform specific tasks. In simpler terms, they’re the brains behind the operation.

- Human-Machine Interfaces (HMIs): HMIs act as the bridge between humans and machines. They provide operators with a visual representation of the industrial process and allow them to interact with the system, making adjustments or overriding commands when necessary.

Why Are Industrial Control Systems Important?

Industrial Control Systems play a pivotal role in improving industrial efficiency, safety, and productivity. By automating processes, reducing human errors, and providing real-time data, ICSs enable companies to optimize their operations and minimize downtime. They also enhance worker safety by remotely monitoring and controlling hazardous environments.

Security Risks and Challenges:

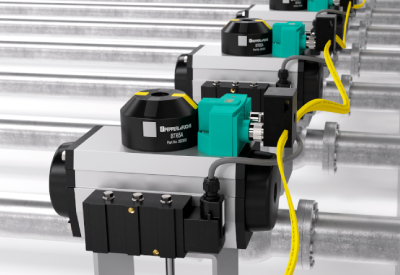

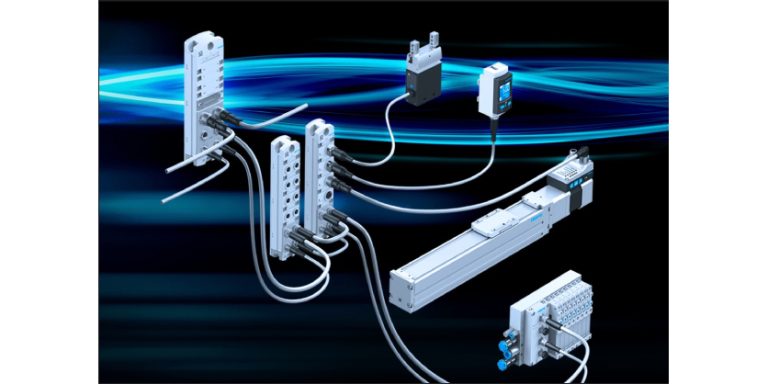

As a market leader in industrial control systems (ICS), Noark Electric delivers a range of Industrial Control System products that provide proven performance throughout the entire life cycle of each device, while delivering high quality at competitive prices. With Noark’s products, you will be able to automate processes, guarantee safety, reduce manufacturing costs, and improve the reliability of industrial control systems. As a result of our Industrial Control System (ICS) products, factories and industrial processes will run more efficiently, with less downtime, which will lead to higher profitability for our customers in the long run.

We offer a variety of Industrial Control products, including Motor Contactors and Overload Relays, Safety control relays and contactors, Manual Motor Starters, Solid State Soft Starters, Pilot Pushbuttons and Indicator lights,, which offer reliable, high quality solutions to a variety of industries and applications. For more information about the specifications and features of each of our individual components, take a look at our product pages.

Make Noark Your Go-to Manufacturer for Industrial Control Components

By automating and managing industrial processes, ICSs contribute to increased efficiency, productivity, and safety. Whether you find yourself intrigued by the inner workings of large-scale industries or simply appreciate the role technology plays in our everyday lives, understanding ICSs can be a fascinating journey. So, next time you see a factory in action, you’ll know what’s keeping it all in control!

More Information

To stay up to date on all Noark Electric products, news, and to receive free resources, sign up for Noark’s Newsletter.

Related Story

Noark Electric and EPLAN Partner with 4,500 New Components

Noark Electric is proud to announce that they have partnered with EPLAN to provide over 4,500 new components to their Data Portal, a step that will improve the level of high-quality electrical components available to North American businesses.