Making the Sustainable Transformation of the Process Industry a Success

March 25, 2024

By Krystie Johnston and Dr. Manfred Jagiella

Sustainability facilitates opportunity when approached with a mindset to preserve resources and promote circularity. We share one Earth, and it is our global responsibility to care for it for the next generation. Endress+Hauser is one global company that understands this responsibility – and practices it as well.

The company began as pioneers in the field of electronic sensor technology in 1953. Since then, they have become one of the world’s leading providers of process laboratory measurement technology, automation solutions, and services. As a family-owned company, they have a special culture that shapes everything they do. Strong values and principles make them a reliable partner. Among their core values are commitment, excellence, sustainability, and friendliness. In this article, Dr. Manfred Jagiella, member of the Executive Board at Endress+Hauser, discusses sustainability, how it is transforming the process industry, and how this can be done successfully.

Question 1: There is a lot of discussion about sustainability today. Topics such as energy transformation, decarbonization, circular economy, and resource and energy efficiency are top of mind for many people and businesses, especially those in the process industry. Are these ideas new? Why are these topics so important today?

The ideas of sustainability, including energy transformation, decarbonization, circular economy, and resource and energy efficiency, are not new. However, they have gained significant importance today due to increasing environmental challenges, such as climate change and resource depletion. These topics are especially critical for the process industry, which is a major consumer of resources and energy and, therefore, plays a crucial role in achieving sustainability goals. As a measurement technology manufacturer, we are in the unique position of being part of the solution on the path to greater sustainability and climate protection.

We provide our customers with technologies for the decarbonization of their processes and applications. Keywords include the production, transportation and use of hydrogen – especially green hydrogen. The same applies to the filtering of CO2 from the ambient air or the separation, utilization and storage of carbon dioxide from the exhaust gas stream.

Question 2: Endress+Hauser recently hosted their first Global Forum to focus on how to successfully manage the transformation of the process industry. How is sustainability transforming the process industry? And how is this transformation creating new opportunities for businesses?

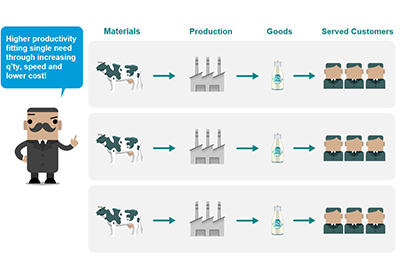

This transformation is largely characterized by the integration of sustainable practices into core business strategies, leading to innovations in process efficiency, resource management, and energy use. As an international company, we want to continue to be successful and grow in an economically and politically volatile environment. In doing so, we face a number of challenges. The shift towards sustainability is creating new opportunities for businesses in the process industry by opening up markets for green products, driving efficiencies, and fostering innovation in sustainable technologies and practices.

For example, we must succeed in making good use of the opportunities offered by digitalization in our products, in our relationships with our customers and in our internal collaboration. Companies are increasingly leveraging sustainability as a competitive advantage, leading to growth and profitability while also contributing positively to the environment.

We are examining how we can reduce the carbon footprint of our measuring devices by saving on materials or using lower-emission materials. We are also looking at retrofit concepts to extend the already long service life of our products even further by replacing the electronics, for example. We are also investigating what opportunities the circular economy holds for us.

Question 3: As a family-owned business, what is Endress+Hauser’s philosophy or approach to their role in sustainability? And what are some examples of how Endress+Hauser is making a positive impact in this area?

As a family-owned business, Endress+Hauser’s approach to sustainability is deeply rooted in its values and corporate culture. The company views its role in sustainability as integral to its mission, focusing on creating value for both its customers and society at large by developing sustainable solutions and practices.

In our own sphere of influence, we will increase the share of renewable energies, reduce our consumption through efficiency measures and, where possible, increase the share of electromobility. We have equipped our product centers with a CO2 dashboard that shows them their greenhouse gas emissions. At the same time, they can see where they stand on the path to decarbonization, measured against our targets. However, we have to make the greatest efforts in our upstream and downstream value chains.

More than a third of our total greenhouse gas emissions are generated on the procurement side. Steel and aluminum, which we use in our measuring devices, are particularly significant here. We work intensively on the procurement of materials and components as well as the design of our products. But it is clear that we can only make progress here together with our suppliers and partners, for example by using green steel and green aluminum in the future.

Endress+Hauser attaches great importance to sustainability and energy efficiency in construction projects all over the world. Our new customer and training center in Burlington, Ontario, is one of the greenest buildings in Canada. Thanks to photovoltaics and geothermal energy, it is not only energy self-sufficient, but also generates more energy than it consumes. The new Endress+Hauser Flow building in Reinach, Switzerland, is also setting new standards. Among other things, we use the waste heat from production to heat the building. And our site in Greenwood IN covers half of its electricity requirements in the production building with a huge photovoltaic system on the roof.

Question 4: Everyone has a role to play in ensuring a sustainable world for generations to come. Turning now to end users and the role they play in sustainability and the circular economy – what can they do to have a positive impact on the climate?

End users play a critical role in advancing sustainability and the circular economy. By choosing sustainable products and services, consumers drive demand that encourages companies to prioritize eco-friendly solutions. Additionally, end users can contribute by adopting practices that reduce waste, such as recycling and reusing materials, and by being mindful of their energy consumption. In the context of the process industry, end users can also influence sustainability through their supply chain decisions, opting for suppliers that demonstrate strong environmental stewardship. This collective effort by end users can have a significant positive impact on the climate and contribute to a more sustainable world.

Conclusion

First impressions make an impact, and the company received accolades with the opening of their Customer Experience Centre in Burlington, ON in the spring of 2022. Since its inauguration, it has achieved both ZCB and LEED Gold Certification, and has won the Rethinking the Future Award 2022 in the Industrial (Built) category. Whether on a local or a global scale, Endress+Hauser is leveraging sustainability advantageously, leading to growth and profitability while at the same time making positive contributions to the environment.

More Information

Related Story

Endress+Hauser Customer Experience Centre Adds LEED Gold Certification

Endress+Hauser Canada’s Customer Experience Centre, which opened officially in 2022, has added LEED Gold certification to its growing list of achievements and accolades as a pace-setter for new sustainable design and construction.

LEED, which stands for Leadership in Energy and Environmental Design, is an international symbol of sustainability excellence and green building leadership. Achieving LEED Gold certification is an especially notable achievement for the multi-use Customer Experience Centre since the 47,000 sq ft facility houses industrial processes that often draw significant energy. These operations include a full-scale Process Training Unit (PTU), state-of-the-art Factory Acceptance Testing and calibration labs, and multi-purpose training and office areas.