Industry Insights with Owen and Shane Carnegie, Looking Back at SPS 2019

April 6, 2020

With the spring tradeshow season coming upon us, and discussions beginning to come up about the new innovations that will be showcased this year it is important to also slow down and think about the innovations that were unveiled last year. We are often so focused on what is coming that we don’t really take the time to consider the full impacts of what we only recently learned about.

In this regard we take a look back at SPS that was held last fall in Nurmeberg with Shane Carnegie, Electronics Product Manager at SEW-Eurodrive. I first met Shane at the Canadian Manufacturing Technology Show where I was impressed with his knowledge and understanding of the growing electronic controls industry and the need to maintain a strong awareness of new advances.

And as Drives & Control Solutions was unable to attend SPS last year I asked Shane some questions about the show and in particular the approach and direction taken by SEW-Eurodrive. (follow the link here to my previous article on SEW’s showing at Hannover Messe 2019).

- 1. SEW has a prominent showing at SPS each year, what is the primary driver for SEW to promote themselves at the show?

SPS is one of the two biggest tradeshows in Germany, with the other being Hannover. SPS is focused on automation systems and components. SEW-Eurodrive uses this show to promote its latest innovations in the application of technology for motion handling solutions.

- 2. Was there a theme or overall product focus or focuses presented by SEW this year?

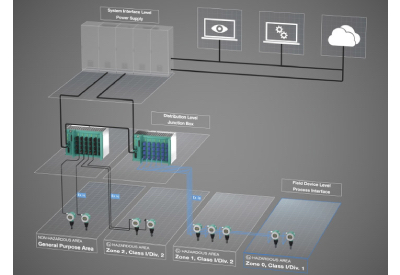

This year a big focus was reducing the system risk for end-users by providing modular solutions from the hardware side and the software side which work together at low risk of failure to the end-user. The software modules are hardware independent.

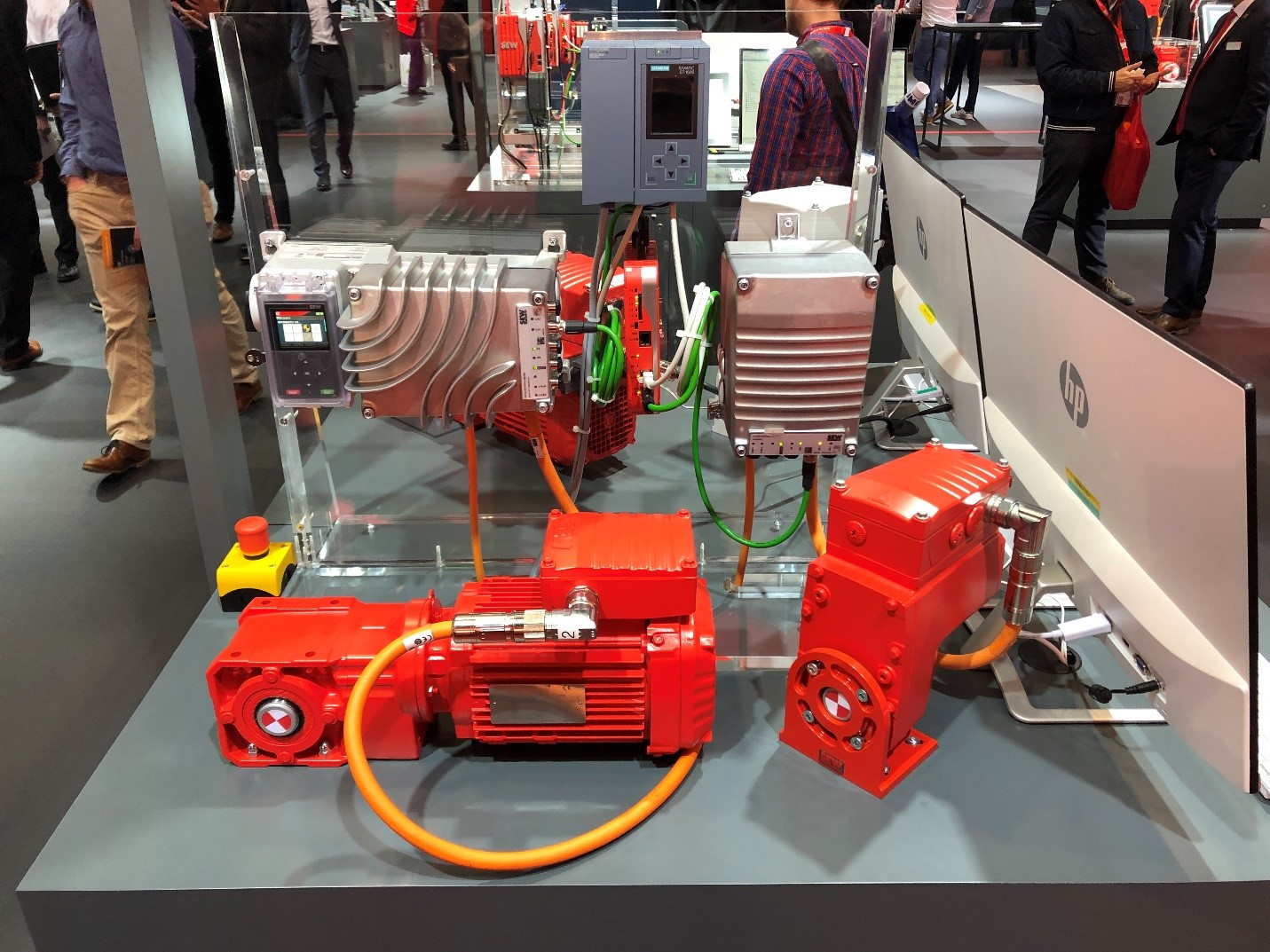

By way of example, MOVIKIT positioning (software module), works the same way from the system PLC (be it Siemens or Allen Bradley) no matter what underlying mechanical gear system you are trying to control (AC gear motor, Permanent Magnet Gear Motor, Linear Motor, electric cylinder, etc.). The theme for SEW is your “one stop solution” for your electromechanical motion control problem.

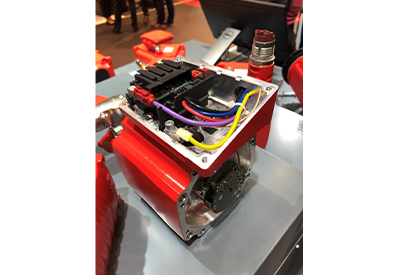

In the theme of reducing risk and speeding up system start-up is the Digital Motor Integration or MOVILINK DDI. This is a single cable installation that carries power & communications and works with our servos and AC induction motors. Same interface. Cable lengths are available up to 200m. When coupled with the factory loaded MOVIKIT, you get automatic motor commissioning. All you have to do is apply power to the motor and connect communications such as EtherNet/IP or PROFINET. Then set an IP address, and send the appropriate process data words and off the motor goes. Also available with EtherCAT and EtherCAT with Beckhoff’s CiA402 interface.

- 3. Tell us about the new products or solutions that were unveiled and when they are expected to reach the Canadian market?

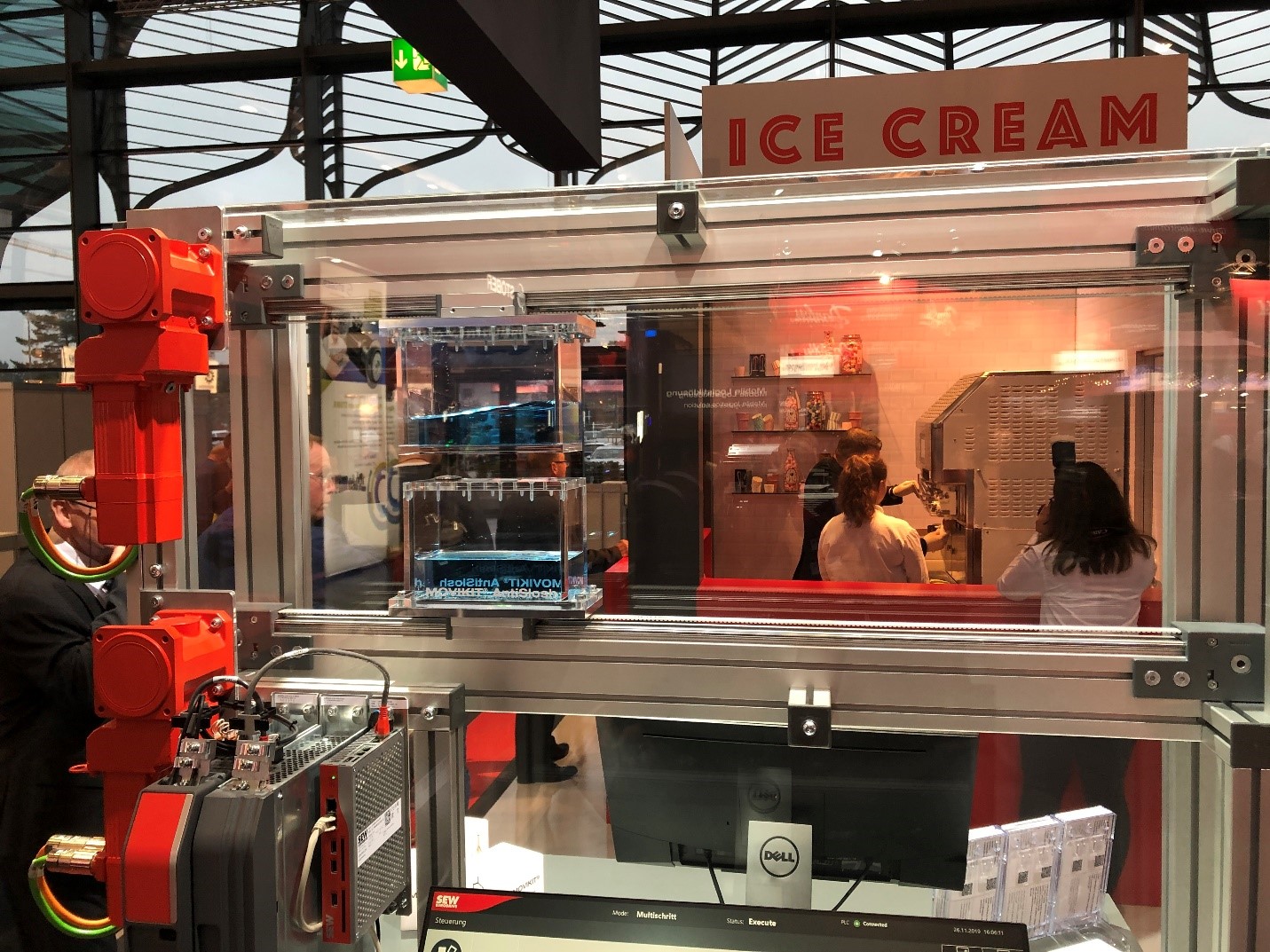

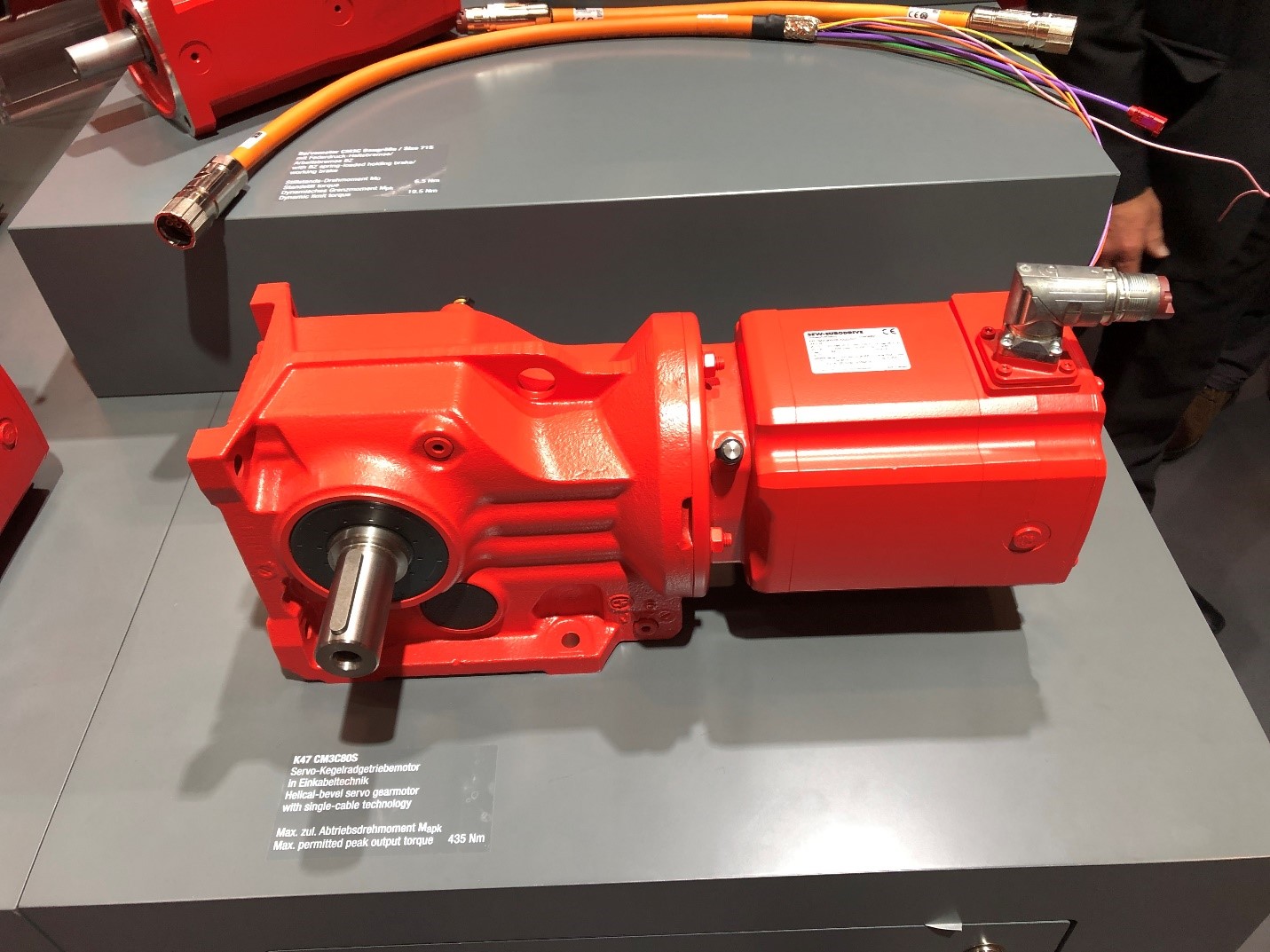

The new MOVI-C Automation system was the focus of the tradeshow booth. Existing products were highlighted in action. Upcoming products to be released over the next year are the CM3C next generation servo motors. The new PxG line of planetary gearing. The new MOVI-C Decentralized products where you simply run power & control communications to the system and the MOVIGEAR or MOVIMOT is ready to run. No panel required.

MOVIGEAR and MOVIMOT have their VFD, Motor & gearbox integrated into a single modular unit. These units have Ethernet/IP, PROFINET or EtherCAT, etc. interfaces directly on board the unit. They are loaded with either a MOVIKIT velocity or MOVIKIT positioning software module and are ready to have their speed adjusted or do positioning. The communications interface is selected at time of order. You can also select your MOVIKIT to be preloaded at the factory. Simply set your IP address via BootP and send your process data words from the system PLC and off they go.

MOVIGEAR is already available. MOVIMOT is due to be released in early 2020. Other interesting products released were our updated line of MOVI-C controllers that run using the Codesys platform with their associated MOVIiKIT software modules.

An interesting upcoming MOVIKIT is the anti sway MOVIKIT which gets rid of the swing on crane hoist when transporting a heavy load. It suppresses the dominant resonant frequency in a system.

- 4. From your perspective just tell us a little about the show in general.

The show is huge. 12 halls! Thousands of exhibitors spread over these 12 halls. You can spend three days wandering the show and never go back to the same company twice. This is the downside of this big show. Plan what you want to see otherwise you could end up spinning your wheels and not really seeing what you want.

You will get to see impressive exhibits from every significant player in the automation and controls industry. All the latest technology you could imagine that could be used in a highly competitive industry. I would highly recommend this show to anyone who wants to make sure their facility remains competitive in this global industry.

- 5. What value would you stress to any Canadian companies considering making the trip to attend SPS in the future, and in particular those interested in visiting and learning about the progressive solutions being developed by SEW?

Europe is a highly competitive market due to short distances. In certain respects, North America is still somewhat sheltered from competition due to distances involved. You can see the huge competition between the various booths on display. Particularly for local machine builders. Companies can easily fall behind with the rapidity of new technology coming out, causing trouble for end-users in regard to the ability to implement the most modern technology and remain relevant in the growing market. For end-users, you will see the latest equipment to keep your plant competitive in this global market.

The SEW-Eurodrive booth was all about reducing the risk for the end-user with a tried and tested motion control solution. The software, controller and electromechanical gear motor have all been tested to work together to achieve your desired result in a single source from SEW-Eurodrive.

For more information, visit www.sew-eurodrive.ca.