Induction Welding with Chillers

May 12, 2020

Electrical enclosures need cooling units in order to enhance performance and prevent failure. The acceptable operating temperature for most electrical devices exceeds 40 °C (104 °F).

Devices often placed in cooling enclosures include variable frequency drives (VFDs), servo drives, programmable logic controllers (PLCs), starter kits, power supplies, inverters, relays, terminal blocks, indicator lights, and transformers. These systems can be protected by a cooling unit that uses either a water or water/glycol mixture.

In addition to temperature, operators are often concerned about condensation. Moisture around electrical equipment will cause corrosion, compromise resistivity, and increase the risk of short circuiting, which causes equipment failure. These in turn may cause more dangerous sparking and fire.

Industry Issues Solved by Induction Welding with Chillers

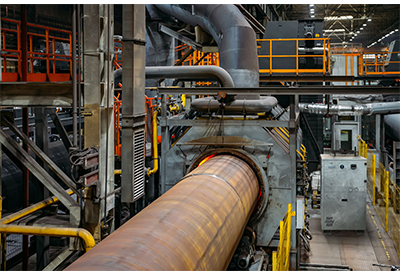

Chillers are used across a wide variety of industries to solve a host of issues. Traditional metal practices are time consuming and inefficient. Using traditional metal practices increases material and time costs significantly. Heating equipment takes a lot of time and therefore uses a lot of energy. However, the removal of heat is necessary in order to maintain structural rigidness as well as to solidify material in the welding process. Additionally, equipment requires physical contact for frequent maintenance. Equipment designs need to ensure it is serviceable. Safety is also a huge concern with traditional welding or heating processes. Manufacturers also seek equipment with a small footprint relative to capacity and need a short lead time.

Induction solves many of these problems because it generates heat from within the object instead of an external heat source, saving energy and making it safer to use. Automated induction longitudinal welding is a reliable, high-throughput process.

Benefits of Liquid Solutions for Electrical Enclosure

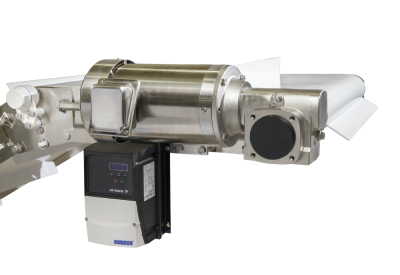

When unfavorable, high temperature ambient conditions exist, convection alone cannot adequately maintain an acceptable operational temperature. An air-cooled liquid chiller is ideal for removal of concentrated heat from process equipment.

Solutions for Cooling Equipment Effectively

Factors to be considered when choosing a system for cooling an induction process, including cost, space availability, existing utilities, energy and water usage, equipment location, potential freezing, reliability, and maintenance.

A smart controller in the cooling system will set the minimum and maximum water temperature with an alarm. Plus, a flow switch will trigger an alarm if the flow is too low, protecting equipment from being cooled. In addition, it will have a non-ferrous tank and piping to reduce corrosion and a thick powder coating on the stand-alone chiller, and reliable, easy to read fluid indication level readout.

By using the proper temperature setting points, operators improve performance and increase the lifetime of devices. Highly efficient cooling technologies generate cost savings and preserve electrical equipment. Pfannenberg Inc. specializes in just this type of technology. Their air-cooled liquid chiller is ideal for removal of concentrated heat from your process equipment. Operators want to select chillers that have a small footprint for equivalent capacity which is offered in their product lines as well.

For more information, visit www.pfannenberg.com.