HELUKABEL’s Critical Keys to Selecting the Right Cable Manufacturer

May 2, 2022

As we began 2022, global material shortages and rapidly increasing costs have now become the new reality. The types of materials that have suddenly become difficult to procure are wide-ranging and include computer chips for automotive manufacturing, wood for new construction, and electrical components – just to name a few.

These shortages have created great uncertainty, which is reflected in a recent poll of contractors in the U.S. by the Chamber of Commerce. They reported:

- •83% are experiencing product delays.

- •71% are struggling to meet schedule requirements.

- •68% are experiencing delays expected into 2023.

- •58% are putting in higher bids on projects.

- •53% are saying major project shutdowns/delays are a top concern.

- •41% are saying material shortages continue.

- •39% are turning down work opportunities.

One of the major material components that affect the cost and availability of wire and cable is copper. This widely used metal, which traditionally has been a volatile commodity, has been steadily increasing in price, which is due to several supply and demand issues.

On the supply side, some of the largest copper mines are seeing their reserves dwindle; they are having to dramatically slow production due to major capital-intensive projects to move operations from open pits to underground.

The world’s second-largest copper mine, Grasberg, located in Indonesia is emblematic of the problems copper miners are facing. The mine began as a large open pit, but after decades of extraction operations the easy-to-reach ore is gone, and future production is expected to come from a deep cave deposit known as the Deep Mill Level Zone. Copper concentrate exports have plunged dramatically as operations shift from open pit to underground according to Reuters.com.

Major South American copper mines have also been forced to cut production. State-owned Codelco has said it will scale back an ambitious $40-billion plan to upgrade its mines over the next decade. The world’s largest copper company also said it will reduce spending through 2028 by 20 percent, or $8 billion.

On the demand side, copper’s widespread use in construction wiring, piping, and electrical transmission lines, makes it a key metal for civil infrastructure.

Additionally, the continued move towards electric vehicles (EVs) places a huge demand on copper. In EVs, copper is a major component used in electric motors, batteries, inverters, and wire harnesses. An average electric vehicle contains about four times as much copper as a regular, gas-powered vehicle.

Copper is also found in the charging stations, which are continuing their own infrastructure ramp up to support the growth of the EV market. A Level 2 charging station requires 15 pounds of copper, a direct current fast charger (DCFC) or a Level 3 station uses 55 pounds.

BloombergNEF forecasts by 2040 there will be a need for 12 million charge points, each requiring about 22 pounds of copper. Currently, the number of charging stations recently passed the one million mark.

Due to the shortages in supply and increases in demand for copper, significant disruptions to electronic and electrical component supply chains are occurring, which result in longer lead times. Unfortunately, they are not product, series, or manufacturer specific, so the best way to mitigate this issue is to give full visibility to your manufacturing partners and allow them to manage and leverage the supply chain effectively.

When selecting a wire and cable manufacturing partner during these uncertain times there are a few key factors to consider:

Inventory

One of the best ways to mitigate ever-changing lead times with wire and cable is choosing a manufacturer that is committed to inventory. Many manufacturers have scaled back inventories in fear of rising copper costs. HELUKABEL maintains a significant amount of inventory in a wide variety of single and multi-conductor cables at our North American warehouses with additional stock at our automated, 1.8-million-square-foot logistics center in southern Germany. Having multi-million dollars of stock on the shelf serves as a hedge to minimize lead times.

Lead Times

As manufacturing continues to manage supply chain shortages, delivering product solutions rapidly is critical to customers. At HELUKABEL, we pride ourselves on industry-leading logistics and are committed to quick deliveries. With the significant amount of inventory in North America, orders placed will ship the same day or within a few business days to our valued distributor partners or direct to our customers. Every week we receive an air shipment from Germany, which allows us to provide access to our European-stocked materials in as little as four days. For those customers that want to have material on order, but don’t need it immediately, bi-monthly ocean shipments from Germany to North America are available, and products can be reserved/staged for future shipping when customers need it, just-in-time.

Flexibility

Finding stock on wire and cable and having it delivered quickly are important, but minimum order requirements can be equally crushing to manufacturing. When a customer needs 350 feet of cable but is forced to purchase a 5,000-foot reel, especially as copper costs continue to escalate, it can be devastating. All that extra cable provides no return on investment and ultimately affects a project’s profitability. HELUKABEL offers little to no minimum order requirement and provides the service of cutting and re-spooling cable as needed.

Customization

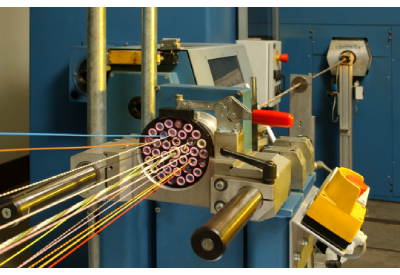

When it comes to sourcing, purchasing material that is on the shelf is always ideal. At HELUKABEL, we have a portfolio of over 33,000 products. Occasionally, there is a need for something unique because what is on the shelf just won’t work. Designing and manufacturing a custom solution is another advantage where we can partner with you. HELUKABEL is at the forefront of the cable and wire industry with our innovative and cutting-edge designs. Our customers expect extreme resistance to chemical, electrical and mechanical stresses, small bending radii, a high number of flexing cycles, and an outstanding lifespan. Our research and development teams are constantly working on creating new, top-of-the-line products that meet and exceed our customers’ ever-changing application requirements.

Responsiveness

The phrase “time is money” is more apparent now than ever. For mission-critical projects, a delayed response, or worse yet no response, can make the difference in meeting a deadline or failing to do so. It can be frustrating to leave an important message in a voicemail system with the hope that it may be listened to and responded to at some point in the future. HELUKABEL strives to have every call answered with a knowledgeable inside or outside salesperson to assist our customers with their requests.

Local Support/Global Reach

At HELUKABEL we achieve quick deliveries by having our North American operations strategically located near Chicago, Illinois(US), Toronto, Ontario (CA) and El Marqués, Querétaro (MX). We also provide local support with a sales team throughout each country. Additionally, with 59 locations in 37 countries throughout the world, we can support our customers that heavily export or may also have global locations to provide seamless support around the globe.

Stability

We live in uncertain times. As our industry continues to consolidate, there is often news of acquisitions and mergers. These can create confusion as contacts can change and new relationships must be made. HELUKABEL has been privately held for more than 40 years and stands ready to serve our customers today and into the future.

As our industry continues to experience historic material shortages, longer lead times, and rocketing material costs, it is more important than ever to partner with a manufacturer that is positioned to weather this storm. We maintain our commitment to inventory and stand ready to quickly respond to any wire, cable, or cable accessory you need and provide you with a truly worry-free experience!

Article Download

To view this article in our digital download center, click here