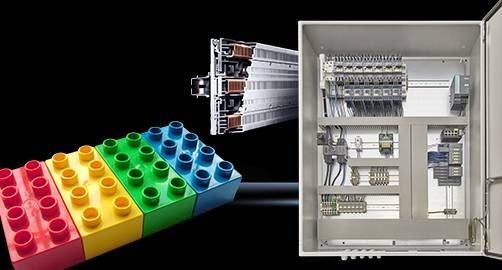

GSA GmbH installs RiLine Compact busbar system, like Lego blocks!

January 2, 2019

The three-member team of GSA Elektrotechnik approaches their projects with much enthusiasm and joy. This includes finding and using new products such as the new RiLine Compact that was used for the first time for a heat recovery system.

The team of GSA Elektrotechnik und Engineering GmbH believes that work must be fun! That’s why Michael Sostek, Mansour Ghassemi and Raimund Brixa met in 2006 to fulfill their long-cherished dream of being happily and gainfully self-employed.

“We wanted to set up our own company back in 2002 – but first of all, we took the opportunity to build and lead the automation business in a partner company, an ideal way for us to make a decision,” says Michael Sostek, Managing Partner of GSA. “Of course, we have to make money, but that is not our first priority, because it is important to like what we do. And the concept of offering everything from consulting, planning and programming to switch cabinet construction as a whole or only  in individual parts, has proven itself for more than ten years,” explains Michael Sostek.

in individual parts, has proven itself for more than ten years,” explains Michael Sostek.

The spectrum of projects is very diverse, and ranges from serving the needs of many sectors: sewage purification, natural gas compression plants, the food industry, machines and presses in manufacturing technology, the automobile industry, the development of test software as well as heating / ventilation / air conditioning systems in building automation.

RiLine Compact for small switchgear

For Michael Sostek, hardware planning is especially cool and enjoyable. “Picking the best of all the possibilities for a project from a system kit is a bit like playing with lego blocks for adults!”

Rittal’s power distribution systems are very accommodating for this ‘playful instinct’, because the modular busbar systems (holder systems and rails in combination with connection technology, device adapters and fuse components form compact units) can be easily configured and installed quickly. “Thanks to a customer’s request for a heat recovery system, we came across the RiLine Compact,” says Michael Sostek. This new busbar system was specially designed for manufacturers of small control and switchgear systems with a maximum current of up to 125 A. It was the ideal solution for the GSA project. “Our customer needed at least 80 amps. The consideration was to first provide 63 A twice. But of course they would have had to do everything twice. The logical solution: to use 125 A once,” explains Sostek.

Fast Construction

RiLine Compact is a tried and tested system for power distribution, with which various types of protection and switching devices are built on a contact-protected system and supplied with electrical energy. Thanks to the standardized and compliant system technology, the compact busbar system can be used in control systems that meet both IEC and the UL requirements and standards.

RiLine Compact is a tried and tested system for power distribution, with which various types of protection and switching devices are built on a contact-protected system and supplied with electrical energy. Thanks to the standardized and compliant system technology, the compact busbar system can be used in control systems that meet both IEC and the UL requirements and standards.

The GSA team was particularly impressed with the ease of installation. Because the RiLine Compact consists of a base plate, in which busbars are completely protected against contact, they can be easily contacted by a grid in the upper section. Various adapters are available for the construction of switching and protection devices, which allow easy connection. In addition, a connection adapter for connecting the conductors and various function modules for motor control and power control are available.

In a quick setup, the RiLine Compact System displays its strengths. Both the base plates themselves and the components of the system can be mounted safely without tools. Due to the protection against contact points from the beginning, the user is protected against live parts. This increases safety for both the system and the user, saving time and money. “We have equipped all four cabinets for the customer with the RiLine Compact. It is so easy and, above all, safe to use components such as the Adapter to exchange” says Sostek. For him, the system is the perfect solution for any project requirement between 63 and 250 amps.

The key difference

It does not always seem easy for the GSA to compete with larger plant builders. But Michael Sostek is convinced that “you can differentiate yourself through ideas and flexibility”. The company also wants to stand out in terms of design: “Our solutions not only work, they also look good in the end. The aesthetic factor is very important in our work – a key differentiator to many competitors.”

In general, the GSA is characterized by a special approach to customers, employees, suppliers as well as the competition. “We mostly see our competitors as partners. When implementing complex projects, we often have to deal with other companies operating in the same field as us. This has resulted in many partnerships where everyone does what they do best for the success of the overall project!”

For more information, pls contact marketing@rittal.ca or visit www.rittal.com/riline