Gear Motors for Mixers and Agitators

September 14, 2020

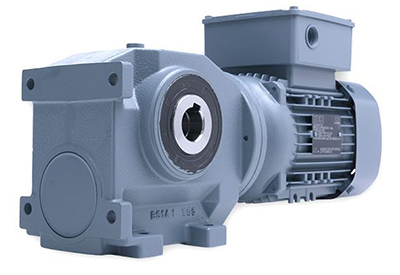

KEB has experience in a variety of applications for our geared motor products, and has been designing and manufacturing high quality geared motors for years. One of these application areas that KEB has focused our geared motor manufacturing on is for industrial mixers and agitators.

German Engineered, Local Assembly

We recognize that there can be difficulties when selecting the right geared motor for your mixing or agitation application. KEB geared motors are German engineered and assembled at our manufacturing facility outside Minneapolis, MN. Our KEB geared motors can be specified in a multitude of gear box, gear ratio, and motor configurations, as well as other customization options (environmental protection options, reinforced, bearings, food and pharma grade paint, etc.). These allow you to tailor our geared motor product to meet your application needs.

Motor Configurations

The KEB geared motor line includes 5 different types of gearing options. KEB most commonly offers parallel shaft and right angle helical bevel geared motors for mixer and agitator applications. However, we also offer inline helical, right angle helical worm, and planetary gearing. In this article, we will highlight some information about the KEB geared motor offering for mixer and agitator applications.

Compact and Efficient

KEB geared motors have an integral design, which means that you will have a more compact package than just your standalone motor and gearbox. Integral geared motors do not require an additional motor coupling since the high speed pinion gear is pressed directly on the motor shaft. This allows for better usage of the available space for your design.

Hollow Shaft

Additionally, the mixer or agitator shaft can be used directly in conjunction with the KEB hollow shaft gear box output, or it can be coupled to a solid shaft output.

Right Angle Output

The right angle output and high efficiency of KEB’s helical bevel design makes it a great choice for your mixing or agitator application. KEB geared motors are energy efficient, and we can supply both IE2 and IE3 efficient geared motors to meet your application need.

Parallel Shaft

The KEB parallel shaft gearbox makes for a great space saver for applications where you don’t have much available space. This allows the output shaft to come along the backside of the motor.

NEMA or IEC Couplings

KEB does offer gearboxes for applications in which you already have a preferred motor supplier. We can offer either NEMA or IEC coupling for the gear box input, and we have inputs for both AC induction and servo motors.

More Options

Additional options that are available for our geared motor design include:

- – Reinforced Bearings on both the drive end and non-drive end of the gear motor increase the nominal overhung load capacity.

- – This can be useful in larger motors that are susceptible to heavier loads, or in applications where you have a high speed output and a low gear ratio.

- – A breather valve can also be installed to prevent pressure and fluid buildup, which could result in bearing failure.

Motor Voltage and Frequency Options

A wide variety of motor voltage and frequency options are available for the global market. 230V and 460V are standard for North American customers, but KEB also offers 208V, 500V, 575V, 690V, and others upon request.

Environmental Protections

Multiple environmental protection options are available. We can supply IP65 washdown motors, as well as gear motors with food and pharmaceutical grade paint protection. This makes a great fit for rugged food grade applications that do not require a full stainless steel solution.

KEB’s high quality, flexible geared motor designs allow us to customize solutions to fit your application.