The Future of Barcodes: Understanding the 2027 Digital Transformation

January 17, 2025

In the world of industrial automation and manufacturing, a significant change is on the horizon. The familiar UPC barcode – a staple of product identification for nearly five decades – is evolving into a more sophisticated system. This transformation, known as “Sunrise 2027,” will revolutionize how businesses handle product identification, tracking, and consumer interaction.

Understanding the New Barcode Standard

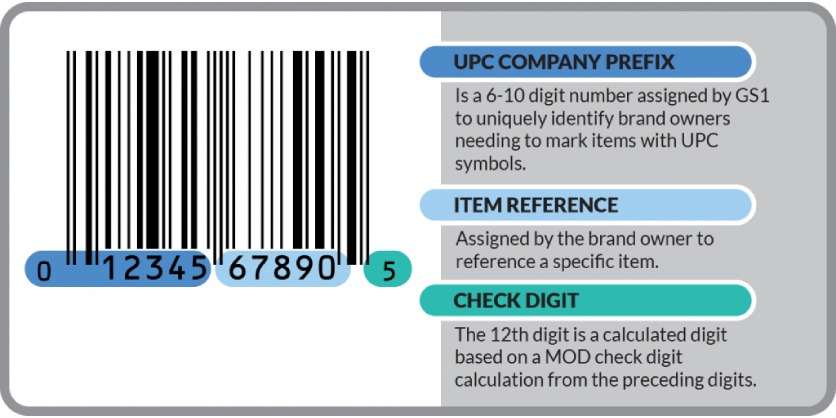

The industrial sector is moving beyond traditional one-dimensional barcodes to embrace an advanced two-dimensional (2D) system called GS1 Digital Link. This new technology combines the functionality of standard barcodes with the versatility of QR codes, creating a single solution that serves both point-of-sale systems and digital information sharing. By 2027, all retail point-of-sale systems are expected to have the capability to read these enhanced 2D barcodes.

Transitioning to the GS1 Digital Link system requires high-performance tools capable of decoding complex data. The V460-H0PX Intelligent Reader delivers industry-leading DPM decoding performance with its ‘Auto Everything’ technology, making it a top choice for businesses upgrading their barcode infrastructure.

Benefits for Industry and Manufacturing

This evolution in barcode technology brings significant advantages to industrial operations:

- Enhanced Data Capabilities

- Storage capacity for thousands of characters compared to traditional UPC’s 12 digits

- Direct access to digital product documentation and specifications

- Improved supply chain visibility and traceability

- Real-time access to product authenticity verification

- Streamlined Operations

- Single barcode for both consumer interaction and point-of-sale scanning

- Reduced manual data entry requirements

- More accurate inventory management

- Enhanced product recall capabilities

- Quality Control Benefits

- Automated expiration date monitoring

- Improved counterfeit prevention

- Better control over product lifecycle management

- Instant access to product safety information

The Transition Period

During the transition to the new system, manufacturers will need to implement a dual-marking approach:

- Products will carry both traditional UPC barcodes and new 2D codes

- This ensures compatibility across all scanning systems

- Placement guidelines recommend positioning both codes horizontally adjacent to each other

- The transition period allows businesses time to upgrade their scanning infrastructure

What This Means for Industries

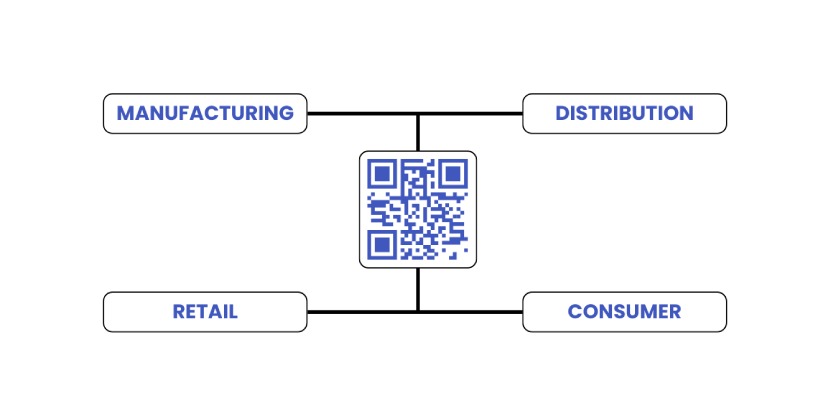

The shift to GS1 Digital Link represents more than just a technical upgrade – it’s a fundamental change in how products communicate information:

- Supply Chain Enhancement

- Better visibility from manufacturing to retail

- Improved inventory accuracy

- Enhanced traceability capabilities

- More efficient recall procedures

- Consumer Engagement

- Direct access to product information

- Enhanced transparency about product origins

- Immediate access to usage instructions and safety information

- Improved customer experience through digital connectivity

Featured Products for the Transition

As industries adapt to the new barcode standards, having the right tools is essential for a seamless transition. Here are four reliable solutions designed to help businesses upgrade their operations and meet the demands of the GS1 Digital Link system:

MicroHAWK V430

The smallest IP65/67-rated industrial Ethernet barcode reader, perfect for compact spaces requiring robust and efficient performance.

V410-H Barcode Scanner

A flexible and easy-to-use scanner, ideal for both industrial and life science applications, enabling businesses to access the rich data in 2D barcodes.

LVS-9580 Barcode Verifier

A high-performance handheld solution for off-line barcode verification, ensuring compliance and quality control throughout the transition.

V275 Barcode In-Line Verifier

This thermal printer-integrated label inspection system simplifies in-line verification for dual-marking systems, ensuring smooth operations during the transition period.

Looking Ahead

As we approach 2027, businesses across all industries will need to prepare for this technological shift. The transition to GS1 Digital Link represents a significant step forward in product identification and tracking capabilities. Understanding these changes now will help organizations better prepare for the future of industrial automation and supply chain management.

Related Story

Introducing the Improved Proax Website

Proax are constantly working to improve your experience on their website based on your feedback. From a complete redesign to new features, Proax are working to make it easy to find what you’re looking for.

This post, will highlight some of the recent updates Proax have made to their website to make your experience even better.