Festo’s MS-Series Supports Quality Assurance for Food Producers that Use Compressed Air

August 9, 2024

Food producers who use compressed air in their operations can rely on the MS-Series from Festo to ensure compliance with SQF-Certification

By Krystie Johnston

Festo has a broad portfolio of products and solutions for the food industry. One facet of this offering is their MS-Series compressed air preparation units designed with your needs in mind. These units are fully compatible with guidelines for compressed air contact with food, ensuring food safety and hygiene in your facility.

Confidence in food safety is critical for producer and consumer

It is imperative that food is produced safely. Customers need to be able to trust that what ends up on their table is safe to consume. To ensure the safe quality of food, various standards help ensure this confidence for the producer and consumer. One common standard for food safety in North America is the SQF-Certification, or Safe Quality Food Certification. It ensures confidence in food safety on a global scale among each link in the chain from producer to manufacturer, food packaging producer, distributor, and retailer.

To ensure compliance with standards like the SQF, each of these links in the chain must pass an audit demonstrating they use food-safe components and system designs in their process. For example, in facilities where compressed air contacts food, either directly or indirectly, they must meet minimum air quality recommendations to ensure compliance. Current SQF guidelines recommend air preparation units use a minimum filtration level of 0.01 µm (microns) with 99.999% efficiency at point of use for food contact applications.

The good news is that Festo has packages available today that can be designed or retrofitted into your process to help you achieve and maintain this certification. Watch this video for a brief overview of the MS-Series of compressed air filtration units from Festo.

Steve Bain, Industry Segment Manager for Food and Beverage at Festo has worked in the industry for 13 years. Bain oversees food safety training and design practices for building equipment in the food industry in the U.S. and Canada and manages the end user focus of approximately 40,000 customers. Given his breadth of knowledge about this industry, he discusses how Festo’s MS Series of air preparation units achieve the SQF’s Air Quality requirements at point-of-use for food contact areas.

Air quality and food safety when using compressed air

Bain says that it is quite common to use compressed air to blow on food. Common activities include using compressed air to blow on food to reject items, like potato chips, or to use compressed air to sort food by size, such as rejecting smaller blueberries from larger ones. In these instances, compressed air comes in direct contact with food and introduces a potential source of contamination.

It is also common for compressed air to have indirect contact with food, to clean surfaces that food touches, or to manipulate packaging. Because these activities involve compressed air having direct or indirect contact with food, air quality must be carefully considered to avoid contamination. “It is a pretty common practice to have an air wand next to a machine and to use that air wand to blow debris off the machine. And because you are using that air directly on a food contact surface, it should be treated well to avoid contamination,” he says.

Air quality and food safety have many facets that must be considered. Air quality is defined by ISO 8573-1:2010, which specifies the purity of classes of compressed air with respect to particles, water, and oil – independent of the location in the compressed air system at which the air is specified or measured – and provides general information about contaminants in compressed air systems. As an international standard, it sets the benchmark for air quality on a global scale.

Festo has developed specific solutions that will assist with configuring an air preparation unit that will achieve the desired filtration at point of contact, regardless of what contaminant may be present. “We can go from a liquid water separator to remove liquid. We have filter regulators that could be 40 of five microns. We have standalone filters that could be 40 or five microns. And then we get down to coalescing filters that are one micron, and then 0.01 microns, which is that SQF recommendation. We can do as many modular configurations as you want,” says Bain.

Food safety with respect to air quality is a bit more of an ambiguous topic because it depends on who is defining it. There are many different organizations that set standards for food safety, and not all of them discuss air quality. Moreover, the ones that do discuss air quality with respect to compressed air are not unified. Bain says that SQF-Certification is the most common food safety certification in the U.S. and Canada and offers one of the most definitive definitions of air quality with respect to compressed air and food contact.

A benchmark is set on standards for air quality

SQF Code Implementation Guidance Document states that: The final stage of filtration in these food contact areas should have a rating of 0.01 micron with an efficiency of 99.999%. “This is something that 10,000 plus factories in the U.S. and Canada are SQF-Certified for, they need to maintain that SQF-Certification, and now actually have kind of a hard minimum standard to rely on,” he says.

Given the discrepancies of definitions for air quality and food safety among certifying organizations on a local, national, and international level, it is logical for producers at any point along this chain to adhere to the most stringent guidelines. This not only provides quality assurance for air quality regarding compressed air and food contact but also ensures producers can remain competitive in the industry.

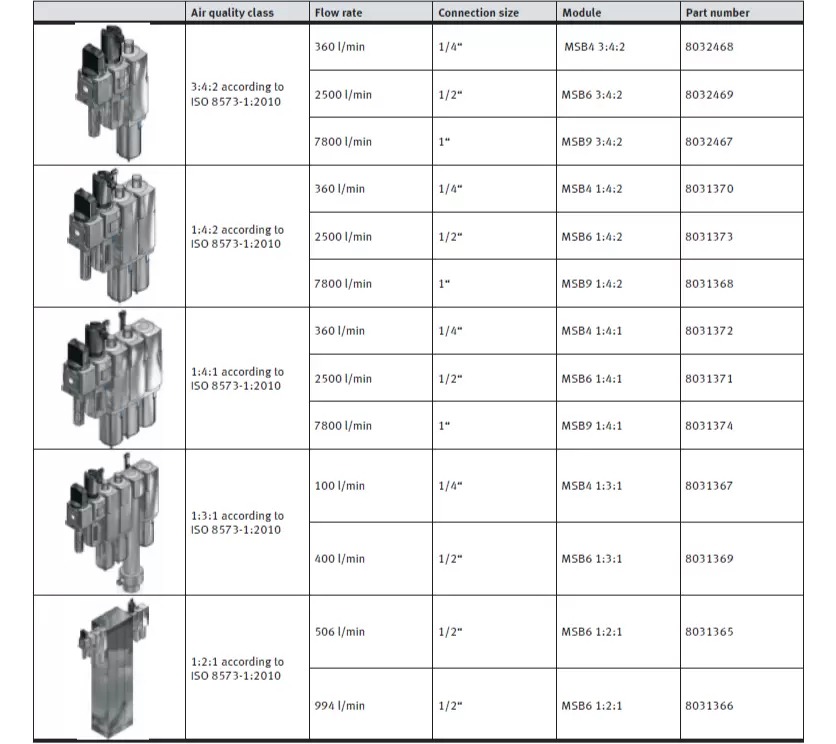

Air quality is being recognized as a crucial step for food quality. Food producers who want to obtain and maintain these standards for air quality can take solace in the fact that Festo has air preparation units that will meet these requirements, and they are easy to configure and install – regardless of whether it is for new equipment or a retrofit. “We have created all these assemblies that have different air quality classes to meet different purities. Every single one of these has a 0.01 micron filter at 99.999% filter efficiency. Every single one of these will meet SQF guidelines,” says Bain.

These preconfigured units from Festo have a range of part numbers categorized by air quality. They are in stock in Mason, OH, and are available to ship in one to three days. Alternatively, with the MS configurator, users can customize their units when the preconfigured units are not enough.

Achieving certification for air quality with respect to compressed air and food contact does not need to be complicated. Food producers can achieve the minimum recommendations for air quality with Festo’s MS air preparation units, and enjoy the benefits that certification provides, such as confidence in food safety and competitiveness in a global food market – today and into the future.

More Information

Interested in learning more about food safety or Festo’s portfolio of solutions that can elevate or maintain your operations? Visit their website today or check out these additional resources:

Whitepaper: Lower the Risk of Food Recalls with Pneumatic Systems Audits and Upgrades

Specific Solutions: Configurable Air Preparation Units

Related Story

Festo Introduces Pre-Configured and Assembled Air Preparation Units that Meet Safe Quality Food Guidelines

Festo has introduced a line of pre-configured, assembled, and tested compressed air preparation units that not only makes specification and ordering faster and easier, but also ensures clean air in food and beverage production. Right out of the box, the new units meet the Safe Quality Food (SQF) guidelines of final filtration stage 0.01 micron (µm) and a particulate removal efficiency of 99.999% at the point of food and beverage contact.