Festo’s Innovative Solutions for Laboratory Automation

May 28, 2024

By Krystie Johnston

ATS Life Sciences Systems relies on Festo’s automation experience to develop customized pipetting solutions that exceed the capabilities of existing liquid handling technology on the market.

Festo in the Life Science Industry

The healthcare industry encounters numerous challenges in meeting demand and time-to-market for new products and innovations. Festo’s Life Science division offers innovative solutions for laboratory automation and medical technology companies to address these challenges. As a leading supplier of pneumatic and electrical automation products, the company supports life science companies such as ATS Life Sciences Systems with customized solutions that meet their customers’ demanding challenges. Ross Bilton, Industry Segment Manager – Festo Life Sciences, discusses a recent collaboration supporting ATS Life Sciences Systems automation needs.

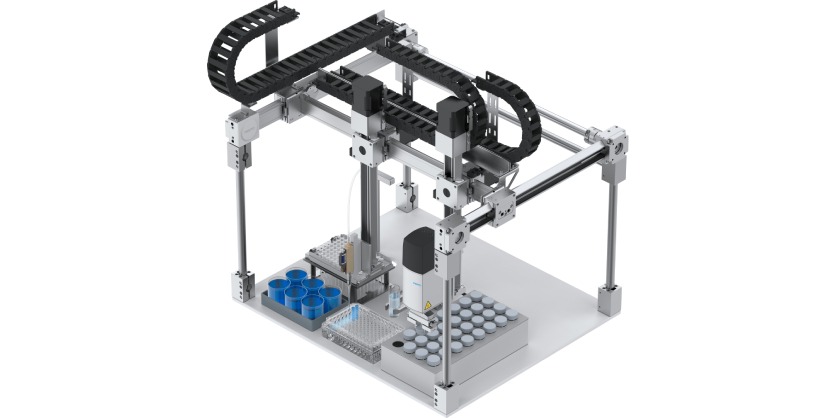

Festo’s automation portfolio includes handling systems (pneumatic and electric) along with control systems for sample, liquid, and gas handling. Gantry systems are utilized in laboratory applications for sorting, decapping, recapping, barcode scanning, sample orientation, and racking. Festo manufactures valves, flow controls, and regulators for medical gas applications, as well as for liquid handling systems to facilitate dispensing, pipetting, and microfluidic applications. The company offers standardized components as well as customized automation solutions to meet the specialized requirements of the medical and laboratory automation industry.

Bilton remarks, “Festo has proactively focused on the Life Sciences industry since 2008. Our integration into the laboratory automation market was a seamless transition from our traditional industrial automation application. Festo’s experience with high throughput handling, assembly, and packaging of small parts transitioned well into the lab automation market. While we needed to understand the key differences in system requirements, such as environmental and regulatory factors, the core of our product and engineering capabilities suit multiple industry needs.

Festo serves international Life Science markets and has an extended team of business development, application engineers, and product managers collaborating across many countries. Understanding global certification and regulatory requirements is crucial, however; the company recognizes that their customers play a critical role in guiding equipment design specifications to meet their market needs.

For example, Festo Canada initiated familiarization with UL61010 standards and human factor design practices in 2012. They subsequently began working with UL and EMC testing organizations to meet regional safety and electrical requirements. The Festo North American regional manufacturing center in Mason, Ohio, holds ISO 13485 certification to further support our life science customers.

“We are exploring additional certifications for Festo Canada to support our market needs. Festo, as one of the largest global automation suppliers, implements industry specialists in each region. This structure allows our team members to collaborate across countries, supporting customer projects, meeting compliance and certification requirements, and managing supplier obligations such as quality assurance and supply chain planning,” adds Bilton.

Festo’s Life Sciences Products

Festo’s liquid handling products are part of the company’s core competencies in fluid power and control. They use pressure and vacuum as the media driver, with consideration for valve design and electronic controls to manage flow and volume requirements. This provides a flexible liquid handling process that easily integrates into high-throughput automation systems.

Moreover, Festo’s liquid handling solutions can be integrated into cartesian, 6-axis, and SCARA robot applications. A key feature of our control systems is the ability to independently manipulate parameters to reach the desired output objective. With a pressure-over-liquid dispense system, a Festo VEAB piezo regulator provides precise closed-loop pressure control, and the controller (PLC or PC-based) is used to characterize the valve settings and continuously monitor pressure setpoints and sensor inputs.

Optimizing valve and manifold design is essential to flow characteristics. Festo can further expand this solution and improve the performance of this system with their PLC and VAEM high-speed valve controller to tune multiple valve heads for multi-channel control. Inline pressure and flow sensors optimize system performance with closed-loop feedback. Festo’s engineering team can test and validate their customers’ applications with support from their global LifeTech R&D centre in Marlborough, Massachusetts.

Another aspect that differentiates Festo’s technology from the existing market is their ability to integrate a liquid handling solution into a complex robotic system through collaboration with their mechanical and controls engineering teams. Bilton says, “Often, our customers are looking for solutions that solve a process or workflow challenge. Having the ability to work with one supplier that can design a system with liquid handling, motion, and controls elements integrated into a single solution ensures that the workflow and functional specifications are met.”

There are several applications where customers require the automation of laboratory processes. The diagnostic space is one such area. “We have customers who successfully integrate these solutions into diagnostic instruments and require a flexible system to manage various liquid volumes and types. Another area of use is in the production of reagent kits or test packs that are required for use with diagnostic instruments. The former example is where our customer needs to build instruments that have reliable liquid handling processes to transfer reagents from one media source to another,” says Bilton.

“These systems are typically benchtop or standalone instruments requiring minimal footprint design to maximize use of lab space. The latter example is in the consumables production for diagnostic instruments. A typical IVD application requires multiple reagents to interact with the sample to produce test results. These consumables need to be produced in high volumes to support the instrument market needs and are closer to a traditional ‘industrial’ automation systems. Festo has solutions to meet the needs of the full production process – for parts assembly, filling, packaging, and quality testing,” adds Bilton.

The need to reduce wait times and improve process workflows is driving the trend in automation for many laboratory processes. Having a system that can deliver patient results faster, more precisely, and in a smaller footprint – while enabling technicians with walk-away time to engage in more efficient tasks – are common factors driving automation in the diagnostics market. “Festo’s ability to integrate this technology into high-throughput ‘traditional’ automation processes allows our customers to build automated production lines that can deliver laboratory instrumentation performance,” says Bilton.

A Closer Look at Festo and Their Client, ATS Life Sciences Systems

ATS Life Sciences Systems (ATS LSS) is a global solutions provider specializing in high-performance and precision turnkey automation systems. Their engagement across various industries provides them with the experience to utilize solutions and deliver systems that meet customers’ process and workflow requirements. Integrating these solutions into laboratory processes can draw on solutions utilized in pharmaceutical production, medical device assembly, or diagnostic production. In the Life Sciences market, ATS LSS delivers high-throughput and precision equipment to meet the increasing demand for high-performance instrumentation.

As a long-standing customer, ATS LSS has worked with Festo’s team to develop a customized pipetting solution based on an open protocol for software integration that broke the limits of existing solutions on the market. “When Festo first presented this technology to the application engineering team at ATS LSS, it was immediately recognized as a viable alternative to existing market solutions. What increased the visibility for the Festo pipette solutions is the open protocol for software integration. Many existing suppliers in the market provide viable solutions; however, when the control software is supplied as a ‘black box’, it becomes a limiting factor for integration into broader automation systems,” says Bilton.

The laboratory automation market has long suffered from the resistance of equipment suppliers who allow limited or no access to the firmware of their product. Limiting the access to control software restricts the integration capability when building custom automation. Because the company does not rely on proprietary software platforms, they provide their customers with the ability to communicate with their devices via various protocols. For example, if a customer wished to design on a PLC architecture, Festo’s system can communicate via CoDySys, or any other EtherNET protocol. For ATS LSS, who develops high-end medical technology and requires dynamic and flexible solutions, Festo’s liquid handling technology was a winner.

For ATS Life Sciences Systems, it was important to develop the technology and instrumentation to manufacture consumables for diagnostics that met the required throughput, and Festo’s solutions addressed their challenges. “Festo took part in many aspects of this automation system; however, our LifeTech applications teams focused on the pipetting process and software integration into the main system. The objective for Festo and ATS LSS was to meet the throughput requirements while maintaining the pipette volume and Cv requirements. This required coordinated control of motion and liquid handling parameters. There was collaboration between both engineering groups,” says Bilton.

Festo Support: From Local Presence to Global Partner

Festo is a global partner, with commercial and technical resources in over 60 countries and a presence in 176 countries. When the company worked with ATS Life Sciences to develop their customized laboratory automation solution, they drew upon their global resources and provided a local touch. In 2018, Festo opened the Technical Engineering Center (TEC) in Boston to expand their R&D team that was in Esslingen, Germany and bring support to the local area. The TEC is a fully operational global R&D center focused on product development, testing, and customer applications.

One of the objectives that the TEC meets is the opportunity to be closer to their customers in the North American Medical and Laboratory market who are developing the latest technologies in their field. Festo’s goal is to provide their expertise in liquid handling and microfluidics to enable their customers to focus on their internal processes and expedite time to market for their technology.

The company specializes in kinematic systems for any industry, and their expertise in liquid handling was an ideal match for the Life Sciences market. “Festo’s broad range of industrial automation products fits into a trend in the Life Sciences industry of increased adoption of automation. Laboratories are automating their processes to alleviate workforce shortages, optimize quality, increase throughput, and allow lab technicians and research to manage their time more effectively. Whether in a lab or traditional manufacturing environment, increasing productivity and quality while simultaneously optimizing employee efficiency enables customers to be more competitive in the market,” says Bilton.

In 2025, Festo will be celebrating 100 years in automation. For their customers in the traditional manufacturing market, they are well-known. In comparison, Festo’s Life Science industry segment is still relatively new. The Festo Life Science team is a rapidly growing group, and to raise more awareness, they are engaging in many activities, such as marketing campaigns, trade shows, industry publications, webinars, and customer innovation days. The company is engaging their current customer base to familiarize them with their LifeTech products and solutions and are constantly engaging in industry organizations and shows to expand their visibility.

Festo is a member of the Laboratory Research & Innovation Group (LRIG), the Society for Laboratory Automation and Screening (SLAS), the Association for Diagnostics and Laboratory Medicine (ADLM), the Advanced Regenerative Manufacturing Institute (ARMI), and many other organizations that support the Life Sciences Industry.

More Information

Related Story

Festo Develops a New Flexible Pipetting Solution

Festo is now showing customers and prospects several new life science automation innovations including the company’s wide-range flexible pipetting. Each of the new and customizable solutions combines Festo components into dynamic subsystems. The company collaborates with OEMs and integrators to bring proven commercial technologies to labs around the globe.