Enhancing Water Treatment Plant Efficiency with Solar Array and Active Harmonic Filtering

April 25, 2024

The search for renewable sources of energy has pushed the electrical industry to look into cutting-edge methods of generating and utilizing power in recent years and Water Treatment Plants are not an exception for being essential to ensuring a clean water supply. This case study explores the partnership between a Water Treatment Plant and Electrotek, a leading provider of Active Harmonic Filters, to establish a hybrid power system that consists of Solar Arrays and Active Harmonic Filters (AHF). The goal was to reduce harmonic distortions and maximize energy efficiency by combining innovative filtering technology with renewable energy, guaranteeing reliable operation even in changing conditions.

Background and Project Overview

Water Treatment Plants consume a lot of electricity, therefore they need dependable and affordable power sources. The operational efficiency and equipment lifespan of traditional grid-based power systems could be impacted by problems like harmonic distortions, power quality problems, and voltage swings. In addition, industries are looking for greener alternatives to conventional energy sources as a result of the growing focus on sustainability.

To overcome these challenges, Electrotek and the Water Treatment Plant worked together to incorporate solar energy and AHF technology into the building’s electrical system. Comprehensive power measurements were taken for the project, both during and after solar panel operation, both with and without AHF. The study also assessed power factor, total harmonic distortion (THD), root mean square (RMS) current, apparent power, reactive power, active power, and power factor.

Results and Analysis

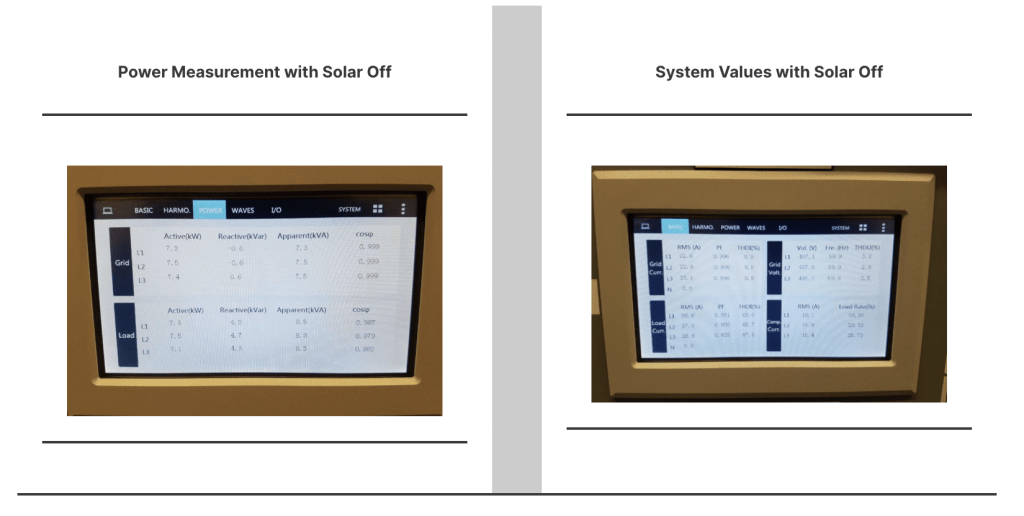

When the solar panels were inactive, the installation of AHF yielded significant improvements in power quality and system performance. With AHF (Grid), the system exhibited higher power factors, reduced THD levels, and lower RMS currents compared to scenarios without AHF (Load). Notably, the power measurements demonstrated improved active power consumption and reactive power compensation, indicating enhanced efficiency and reduced power losses.

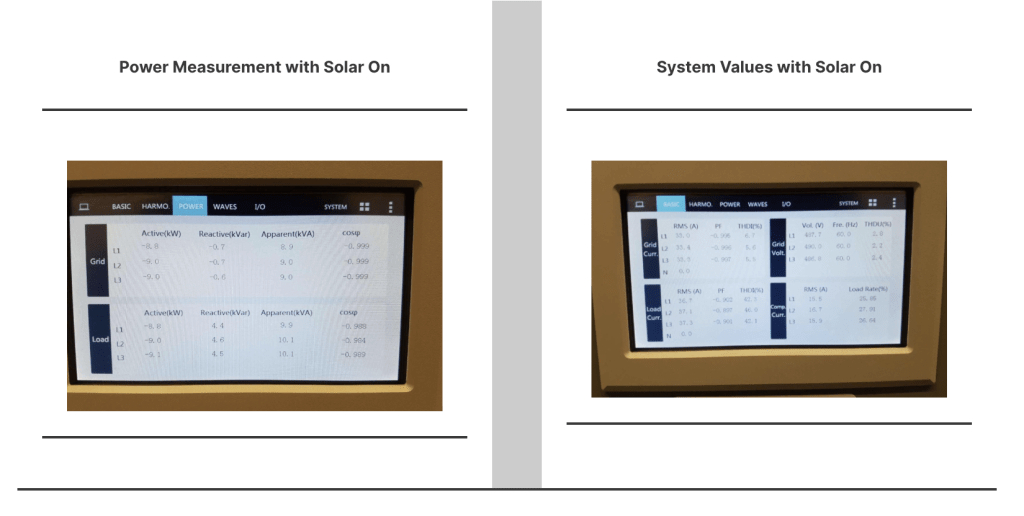

During solar operation, the benefits of AHF became even more pronounced. Despite the fluctuating nature of solar power generation, AHF effectively regulated power quality, maintaining stable power factors and minimizing harmonic distortions. This contributed to enhanced grid stability and reduced strain on electrical equipment which led to operational improvement.

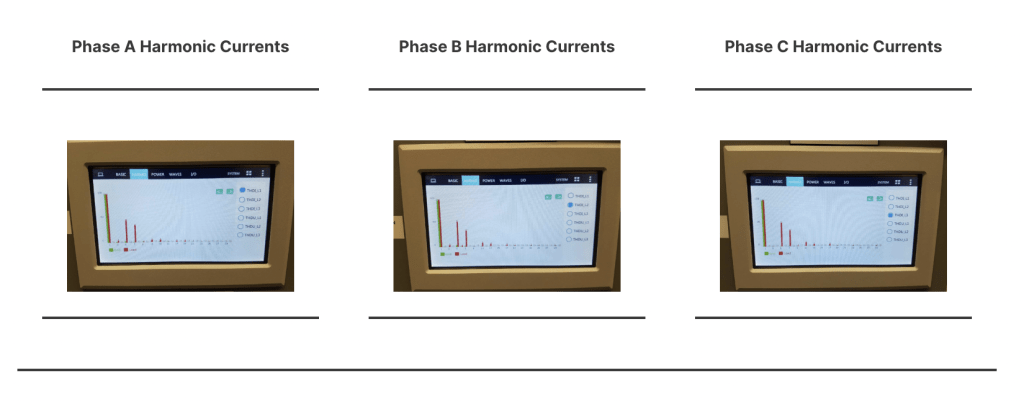

The filters’ effectiveness in eliminating harmonic distortions caused by Variable Frequency Drives (VFDs), which are frequently used in Water Treatment procedures, was further demonstrated by phase-specific harmonic current analysis. The ability of the AHF to reduce harmonic problems and provide smoother, more effective system performance was demonstrated by the contrast between generated harmonic currents (red) and the resulting harmonic currents after AHF cancellation (green).

Conclusion

Electrotek’s partnership with the Water Treatment Plant serves as an example of how cutting-edge filtering technology and renewable energy sources can be used to improve productivity and dependability in industrial environments. In addition to minimizing its environmental impact, the Water Treatment Plant enhanced its power infrastructure by utilizing solar power and applying AHF technologies. This assures sustainable and resilient operations in the face of changing solar energy demand. The significance of new methods in improving the performance and sustainability of vital infrastructure systems has been demonstrated by this case study.

More Infromation

To learn more about how Electrotek’s solutions can optimize your facility’s energy efficiency and reliability, please contact us at sales@vancoelectrical.com

Available at Vanco Electrical Supplies – Certified Distributor of Electrotek

Source: Electrotek – Solar Array with AHF Case Study

Related Story

Vanco Electrical Supplies Ltd. – Distribution, Control and Power Quality Solutions

Vanco aims to provide high quality service and sound technical advice. Whether you are an OEM, Contractor, or facility manager, Vanco will help identify and provide cost effective solutions to your unique challenges.