CADDi Unleashes the Potential of Manufacturing Operations by Transforming Legacy Drawings and Supply Chain Data

October 18, 2024

By Krystie Johnston

Manufacturers today face pressures and challenges that threaten their survival but also opportunities to transform their operations and thrive. Data is the lifeblood of decision-making in the digital era; however, navigating the “digital transformation” can be like walking a tightrope, striking a balance between respecting an organization’s traditions and embracing new technologies. Crossing the divide is possible. It requires an end goal and a strategy to get there.

Growing Pressures and New Opportunities

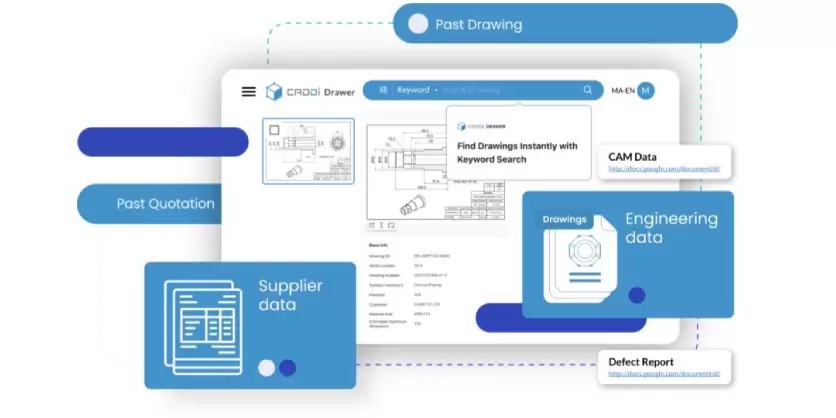

CADDi’s platform, CADDi Drawer, might be the solution you are looking for if you face challenges with your digital transformation, data, skilled labor, or supply chains. CADDi is a manufacturing intelligence software company that makes drawings and supply chain data available to everyone within an organization by leveraging patented AI to aggregate, analyze, and extract everything needed to make better decisions and produce better products.

The company began in Japan about seven years ago and quickly grew on a global company scale. They are now operating in 4 countries around the world and growing. Chris Brown, Vice President of Sales at CADDi, says the North American manufacturing market has latched on to the idea of CADDi Drawer, their AI-powered Software as a Service (SaaS) platform, because it solves several challenges simultaneously.

CADDi recently conducted a survey of over 330 U.S. manufacturing leaders about the pressures, challenges, and opportunities they see. Brown highlights one critical finding, “73% of manufacturing business owners are planning on retiring within the next seven to 10 years. And 68% said that when they leave the organization, their institutional knowledge will be lost forever when they retire. That leaves the rest of the organization without the critical insights it needs to succeed. And that is exactly what CADDi solves for.”

CADDi Turns Siloed Parts Data into Manufacturing Intelligence

CADDi Drawer can maintain this institutional knowledge and answer questions like “Have we ever made this before? If we did not make it, how much did we charge for something similar before? What defects are prevalent when we make something like this? What motion-controlled solutions would we need to connect these five machine parts together and implement motion in them? What motion controls are we using? What suppliers have we used in the past?” Essentially, there is no end to the types of questions CADDi Drawer can answer, and the response time and accuracy of information are unparalleled.

Brown says that CADDi as a company is experiencing a lot of success right now because manufacturers are seeing this SaaS as a potential strategy to bridge the gaps in their industry and unite the old and new. “What we are really recognizing here in the United States, especially now that it is backed up by that data from the market survey report, is that there are a lot of fears about that industrial knowledge being lost in this country. Especially with all of the job mobility that we have seen over the past five to six years. People are changing jobs at record rates right now,” says Brown.

Another challenge that CADDi identifies in the survey is related to the way that institutions store and access their data which creates a critical limitation.

Manufacturing software systems like ERPs (Enterprise Resource Planning), PLM (Product Lifecycle Management) tools, PDM (Product Data Management) tools, and CAD (Computer-Aided Design) programs are designed to serve specific functions within the broader manufacturing ecosystem. Because of this, they fall short of providing holistic and timely information needed to make real-time decisions within an institution. It takes time to track down the relevant information, and that time adds up fast. Moreover, it can be frustrating to wade through the volume of information or do things twice because that is more efficient.

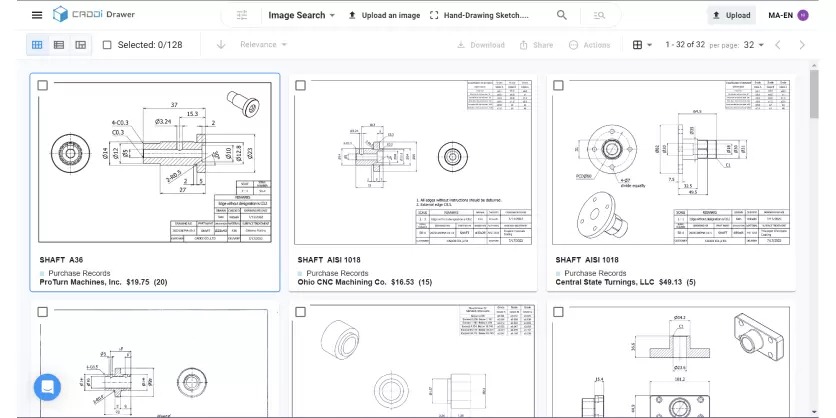

Leverage historical parts data to unleash the potential of your whole team

“Engineers want to be engineers. They do not want to be librarians,” says Brown. “And a big portion of their job is finding drawings. And when it really boils down to it, if it is going to take an hour to dig through all of these files that are stored on network drives, or in PDFs, or PLM systems – whatever it might be – or it is going to take you an hour to redesign it and put it in CAD, an engineer is always going to take the route of, ‘I will just redesign it.’”

Brown points out that one of the features of CADDi Drawer is that their system automatically finds all the duplicated sheets, reducing the volume of documents that need to be referenced, the time spent checking, and perhaps, some frustration.

“AI should not do your job for you – but it should do the research for you. It should feed you data. It should surface things that you do not have the time to and or the capacity to remember,” says Brown. Given the current manufacturing landscape and career lifetime, companies do not always have the luxury of being able to rely on someone’s 30 or 40 years of experience. Employees may not easily remember when a specific part was first made, how and where that information was stored, or be able to quickly produce this information when asked.

With CADDi Drawer, an engineer can sit down and type a seemingly endless number of requests into the platform, and like ChatGPT, the software will search its database and produce the requested information.

Giving an example, Brown types, “I am looking for a motor drive.” And the software produces a list of 1,000 motor drives. He refines his search, “I am looking for one that has a 1,000-kilogram force load.” And the platform produces a list of 20 motors with 1,000-kg force load. He queries further, “And I am looking for one that has undergone saltwater spray tests.” And the list the platform produced narrows to display the motor drive options that meet these specifications.

Brown says that being able to surface that information quickly, without having to go through thousands of motor controls housed within the company’s internal PDF system and having to open every single one of them to find something specific, can be huge to companies in terms of reducing time and costs. And it is easy to get started. As long as a company has been databasing their procurement, engineering, and sales metrics in some way – whether it be an ERP system, a procurement system, or an engineering document management system – they will be able to use CADDi Drawer to make similar queries and get almost instant answers.

Connect Quotation and Other Supply-Chain Data to Drawings

And that is not all. CADDi Drawer can be used to obtain additional insights that may not be obvious without using digital technologies to get the most out of existing data. Brown says that manufacturing companies can leverage CADDi Drawer to gain insights about quality control and supply chain security with information already available in their internal database. This shrinks the divide that companies face in terms of pressure and challenges, offering additional opportunities to achieve their goals more fully.

For example, manufacturers can connect their inbound quality systems to CADDi Drawer and better identify how many defective parts they received. Or they can connect their field service engineering documents to CADDi Drawer and identify trends in the performance of parts in the field to make better decisions in what parts they use in their design. “Really surfacing these insights that are across all of their data would take them hours to find and research. Making it accessible in five minutes or less absolutely accelerates that entire development process,” says Brown.

CADDi’s Definitive Approach to Cybersecurity is Top-Shelf

CADDi’s AI-driven software is supported by a safety net of security, ensuring that the world’s most sensitive and secretive data and intellectual property remains safe and protected. “We follow a lot of ISO standards,” says Brown. “In order to uphold cyber security, we are hosted on Google Private Cloud Networks in order to make sure that Google is helping us protect that data as well. But I think one thing that takes us above and beyond any other AI organization right now is the difference between multi-tenant AI setups and single-tenant AI setups. And we are a single-tenant AI setup.”

For CADDi, being a single-tenant AI setup means that for every customer they bring on, they create a unique environment for them. They retrain the AI tools every single time they bring on a new customer. “It puts more work on us,” says Brown. “However, what that means is that there cannot be any leakage from the AI tool itself. It can never serve information from a different company to the company that is doing the research because it is on a completely separate tenant, a completely separate training model. This really takes us a step above and beyond.”

The founders of CADDi both have backgrounds in prominent companies operating in the manufacturing space. CADDi’s CEO and co-founder, Yushiro Kato, previously worked for McKinsey & Company, where he co-led the procurement sector for the manufacturing industry. And the company’s CTO and co-founder, Akifumi Kobashi, spent years building data processing systems at Lockheed Martin in coordination with NASA and JAXA, and worked for Apple. “They really took the definitive approach that cybersecurity was going to come above anything else within the organization.”

CADDi Drawer Transforms Workflow

CADDi is emerging on the world stage as a company that can help manufacturers unleash their potential. By transforming legacy drawings and supply chain data with an AI-powered SaaS, they are sure to reduce some of the pressures and challenges they face today and create new opportunities for the future.

Interested in learning more? Visit CADDi today.

Related Story

84% of Manufacturing Executives Anticipate a Recession by 2026, According to New CADDi Research

- Nearly half are prepping for a recession within the next twelve months

- Just 11% have a positive short- and medium-term economic outlook

- Research reveals U.S. manufacturers continue to struggle with data issues, talent and supply chain challenges and institutional knowledge loss

While nearly half (49%) of U.S. manufacturers expect a recession to hit in 2025 and an overwhelming majority (84%) think it will happen within the next two years, most are overlooking straight-forward opportunities to lower their costs and drive profitability ahead of a down market, according to new research conducted and released on September 11th by CADDi. The proprietary research, which is based on a survey of more than 330 U.S. manufacturing professionals, reveals that manufacturers are making financial decisions based off incomplete information.