Bosch Rexroth – The Fast Track to Significant Results

November 27, 2018

With IoT Insights Bosch Rexroth brings the analytical potential of the Internet of Things into the production hall and makes optimizing machines and production lines considerably easier. The new system solution contains everything that IoT users, including machine operators and maintenance technicians, need to be able to quickly collect, pass on and analyze data: sensors, a pre-installed IoT Rack including industrial PC and I/O modules as well as pre-installed IoT Gateway software, database and dashboard for local analysis and visualization. With open standards such as OPC UA, the scalable all-in-one solution also enables an optional cloud connection.

For most companies, the issue is not whether they should optimize their production processes but what the fastest way of achieving results is. Bosch Rexroth’s new system solution IoT Insights minimizes the time and costs previously involved in defining and retrofitting appropriate sensor technology, collecting data from various different sources and obtaining meaningful information.

Fast commissioning: IoT Rack and multi-sensor solution

IoT Insights brings together all necessary IoT building blocks to form tailored complete packages. The hardware is bundled in a compact, CE-certified IoT Rack with IP65 protection class – including industrial PC and expandable I/O modules. Inputs and outputs are automatically recognized. Data is currently collected using the multi-sensor solution CISS and in future the network-compatible multi-sensor SCD can be used. As such, up to eight measured values can be simultaneously collected per sensor. In addition, standard sensors can also be connected effortlessly.

Pre-installed: IoT Gateway software, IoT Insights dashboard and database

The pre-installed IoT Gateway software registers which sensors are connected. Alternatively, instead of being analyzed locally, the collected data can also be transferred to cloud services, for example for cross-plant comparisons. The connected sensor technology and controls are selected and parameterized in just a few minutes and, once complete, the data can start to flow immediately. Security mechanisms such as encrypted OPC UA communications, an additional IoT firewall and VPN connections ensure optimum data protection.

The IoT Insights dashboard software for local analysis and visualization is also pre-installed. As with Gateway, configuration is web-based using assistants and widgets. As a result, individual machines and workstations can also be monitored at short notice and without any programming and individual comparisons can be carried out with several IoT Racks in a line. Alerts and messages (e.g. sent via e-mail) inform users of relevant deviations from command values. Pre-configured dashboards, for example for drives and machine tools, simplify the analysis process and deliver swift results. The data history is stored using a structured and standardized approach for subsequent analyses.

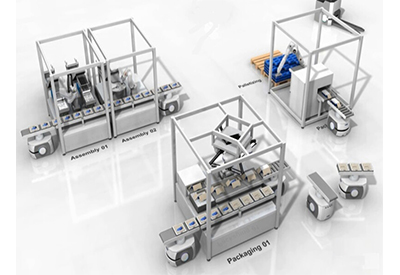

Additional heatmap for value stream analyses

IoT Insights can, for example, be combined with Bosch Connected Industry’s Heatmap software for further value stream analysis. Based on the bottleneck displays in route planner apps, it makes bottlenecks and delays in the value stream immediately visible so that production managers can react straightaway and introduce suitable countermeasures.