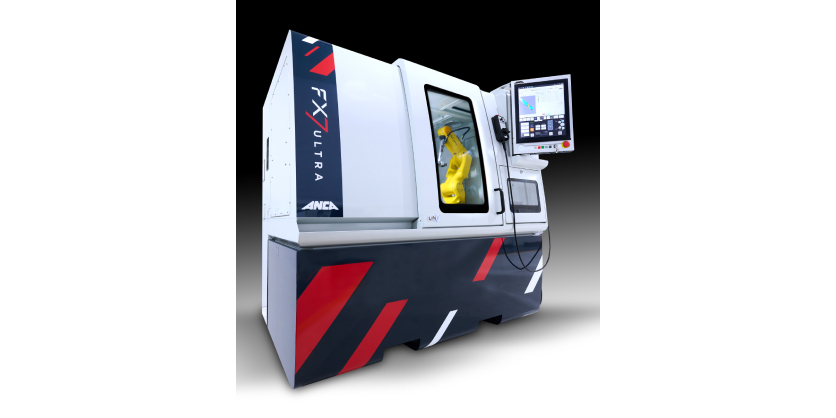

ANCA’s FX7 ULTRA: Ultra Impressive and Ultra Precise. Innovation at its Finest

November 29, 2023

By Krystie Johnston

ANCA’s passion for technology and innovation, combined with their manufacturing expertise has made them a world-leader for flexible CNC tool grinders and cutters, and they are gaining attention in Canada.

From Melbourne, Australia to a world-leading manufacturer

ANCA is a world-leading designer and manufacturer of high-quality innovative products and solutions. Specializing in the niche market of CNC grinding machines, motion controls and manufacturing solutions, their products make the tools and components that contribute to essentially everything used in the modern world. Russell Riddiford, President of ANCA Americas, discusses ANCA’s world-class tool grinders and cutters, including their latest FX7 ULTRA, and their growing presence in Canada.

Founded in 1974, ANCA will celebrate their 50th anniversary in 2024. Co-founders Pat Boland and Pat McCluskey started the company in their garage, and with great passion and vision, have grown the company into a thriving business. Headquartered in Melbourne, Australia, they export 99% of their products to more than 54 countries around the world. Riddiford was part of a team who opened ANCA Inc. in Farmington Hills, Michigan in 1989, initiating overseas growth and fostering sales and aftermarket support. Similar investments followed, building ANCA’s global footprint thereafter. Today, ANCA has offices around the world, supported by a comprehensive network of representatives and agents.

Riddiford attributes ANCA’s success to the innovation and drive of the owners, who remain active in the business, and the fact that they embedded these attributes into the company’s DNA. And to this day, Pat Boland and Pat McCluskey continue to remain active in the company with their passion for innovation.

“They are very innovative and very engineering driven. And technology driven. A significant portion of ANCA’s revenue goes back into R&D, but from the beginning and to this day, the owners have been incredibly innovative. We have many patents on our machines, and we have many first-to-market products, the first being our four-axis tool and cutter grinder released at the IMTS show in Chicago in 1986. At that time, CNC tool and cutter machines were just being developed, and we were the first to put a probe on one. We were also the first to develop menu-drive software and put it on that machine as well. It was very innovative and unheard of at the time.”

Vertical integration and a drive for innovation

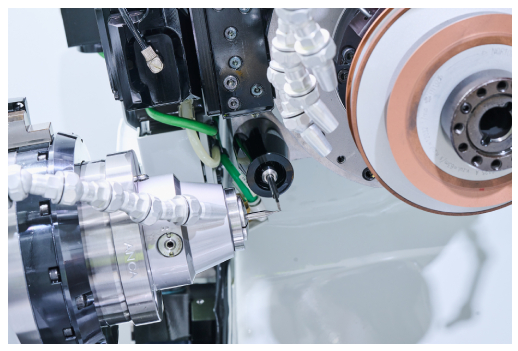

Over the years, ANCA’s continued success is credited to a blend of their highly skilled team and the company’s effective vertical integration in the industry. Because they manufacture nearly all their technology in-house, they can provide their customers with a complete solution backed by quality and expertise.

“ANCA manufactures the base that the machine is built around, we write and develop our own software, we build our own CNC controls and electronics. We own a sheet metal company where we build the canopy and cabinet to house our electronics. We are vertically integrated, and this is unique in the machine tool industry.”

It is these robust capabilities that set ANCA apart in the industry and offer their customers a competitive advantage. When a customer needs to do something unique, ANCA can help them bring new innovations and technologies to the market quickly and easily.

“We have a customer base that has dedicated itself to the ANCA product. They want to be on the leading edge and at the forefront of technology. They motivate us to bring on that next innovation because they have come to expect it.”

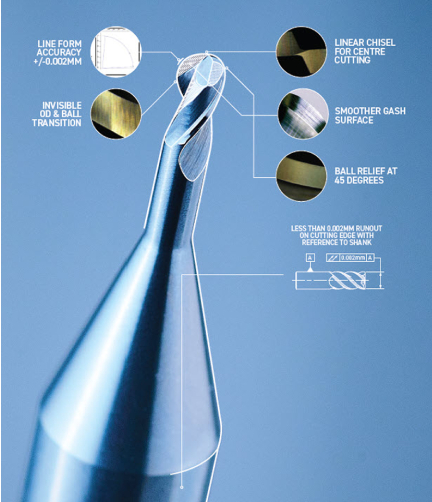

ANCA’s team of engineers and technical experts are more than capable of rising to the occasion and their products have been refined to achieve an ideal surface finish that produces an exceptional product and a genuine “wow” factor in terms of precision and accuracy.

ANCA’s range of products are designed to overlap from start to finish, and are future-proofed

ANCA is renowned for their CNC tool and cutter grinders; these machines are used for manufacturing precision cutting tools and components across a diverse range of competitive industries including cutting tool manufacture, automotive, aerospace, electronics and medical.

“Our product range is quite diverse, but our flagship is the tool cutter and grinder, and we have established a portfolio around the cutting tool industry. We have very big tool and cutter grinders for large manufacturing facilities all the way down to the entry level – they have the same technology throughout – but the difference is based on the size of the cutting tool that the customer wants to do. We have a compact machine with low horsepower for small tools and very big machines with more power for a large diameter cutting tool that would be used to make a turbine blade, for example.”

ANCA also offers a blank prepping machine (the CPX). that precedes manufacturing a cutting or grinding tool and takes the raw material at the initial stages and shapes it before it goes to the tool cutter and grinder. And their AutoMarkX is a laser etching machine used at the tail-end of the process to mark serial numbers, QR codes or company logos.

“ANCA provides a start-to-finish operation for the cutting tool industry. And that in and of itself is quite unique in the industry as well.”

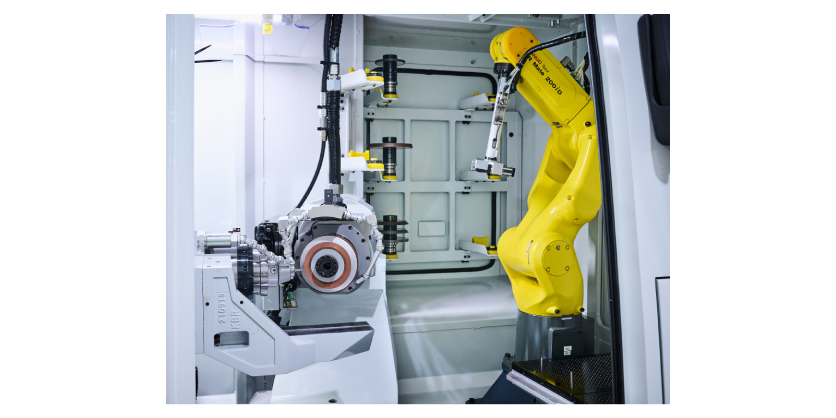

The company has purposely planned these products to overlap from start to finish, anticipating the future where “lights out” production will grow. Their AIMS (ANCA Integrated Manufacturing Solutions) is an automated system that does not require human intervention, from start to finish, allowing a plant to run lights-out and is a future-proofed system that is ready for what is next.

The spotlight on ANCA’s FX7 ULTRA

The FX7 ULTRA is ANCA’s next generation of manufacturing machines. Taking their standard FX7 product, ANCA has added additional features that allow their customers to make a premium product by improving precision and accuracy. Nanometer control is one exciting feature that enables ultra-precise programming of the axes in the machine to anatomically accurate movements – movements so small they are impossible to detect with the human eye.

“Nanometer control is a very high-precision, very small movement. And we can program the machine to move that accurately, that precisely, which is amazing. This allows you to control the smoothness of your axes in their motion, producing a better surface finish on the tool. The smaller the movements are along the axis, the greater the surface finish, which allows the customer to make a premium product that they can sell to their customers; a product that will last longer and produce a better finish on the part they are making.”

Additional features include ANCA’s patented Motor Temperature Control (MTC). This allows the operator to heat up the spindle, as well as cool it down, by controlling any thermal growth of the machine, ensuing consistent thermal stability.

“The ULTRA is an exciting product for us, and the market has caught on to it. It allows our customers to make a premium product for their high-end customers. We have our standard FX7 – which has done very well and suits 98% of our customers because it is still great technology and a beautiful machine – but there is a small market that wants to do a premium product, and now we have the ULTRA product available for them.”

The FX7 ULTRA (and all ANCA’s ULTRA products) come with a three-year warranty demonstrating ANCA’s confidence in this line of machine. For a complete overview of the new FX7 ULTRA, refer to this latest press release: Unleash the Power of Precision: ANCA’s FX7 ULTRA Offers Unparalleled Accuracy for Small Tools Down to 0.1mm.

ANCA grows presence in Canada

For nearly five decades, ANCA has experienced growth around the world by strategically building their sales and aftermarket support. The decision to extend their operations required investing in manufacturing facilities and highly skilled workers. Growth has been matched with investments in infrastructure and R&D to support sustainability. As they built their global footprint, they opened offices around the world, including Europe, Asia Pacific, North and South America.

Recently, ANCA has expanded their presence in Canada. A new application engineer and technical sales expert will serve clients across Canada and play a pivotal role in expanding ANCA’s reach in the grinding industry.

“We have approximately 309 machines in Canada. And we know through the customers we have in Canada, that there is a desire to have more ANCA products there. We put our technician in Canada recently, and Brady is providing technical support to our customer base, and is our connection on a technical sales level.”

The response to ANCA’s increased presence in Canada has been positive.

“We envision more growth. We have had a great response from our customers in the last eight months that Brady has been with us. He came to us with 10 years of ANCA experience from an existing ANCA customer in Canada. We have already picked up additional business from Brady. I am very happy with our progress, and to our existing customers that are there, it has been a wonderful breath of fresh air.”

ANCA has a robust after-sales support service for their customers; including preventative maintenance, technical support, service contracts, training, machine rebuilds, software and hardware upgrades, and a lifetime warranty on telephone support (answered by a real person). No matter where you are in the world, you are guaranteed to receive the highest quality level of customer service from ANCA’s local support teams.