ANCA Celebrates 50th Anniversary and Contributions to the High-Precision Tool-Cutting Industry

June 25, 2024

By Krystie Johnston

In 2024, ANCA celebrates their 50th anniversary by highlighting their contributions to the high-precision tool cutting industry with customers and partners around the world

ANCA was founded by Pat Boland, an Electrical Engineer, and Pat McCluskey, an Industrial Electronics Engineer in 1974, in Melbourne Australia. For 50 years, the company expanded globally. Today they employ over 1200 people worldwide and serve customers in more than 46 countries. Pat Boland, co-founder of ANCA, discusses this journey and some of the innovations they have contributed to the high-precision tool-cutting industry.

Boland says an achievement he is most proud of is a range of their current products on the market today called the ULTRA. This line is setting new benchmarks in the precision tool industry for surface finish and machine accuracy. With the ULTRA line, ANCA’s premium machines deliver batch consistency from tool number one to one thousand.

“We have a number of unique technologies in the motion control field that contribute to achieving that result,” says Boland. One is that the drives of ANCA’s servo control system have moved from conventional PID loops to advanced extended disturbance observer technology, which gives improved path-following capabilities compared to conventional servo loops.

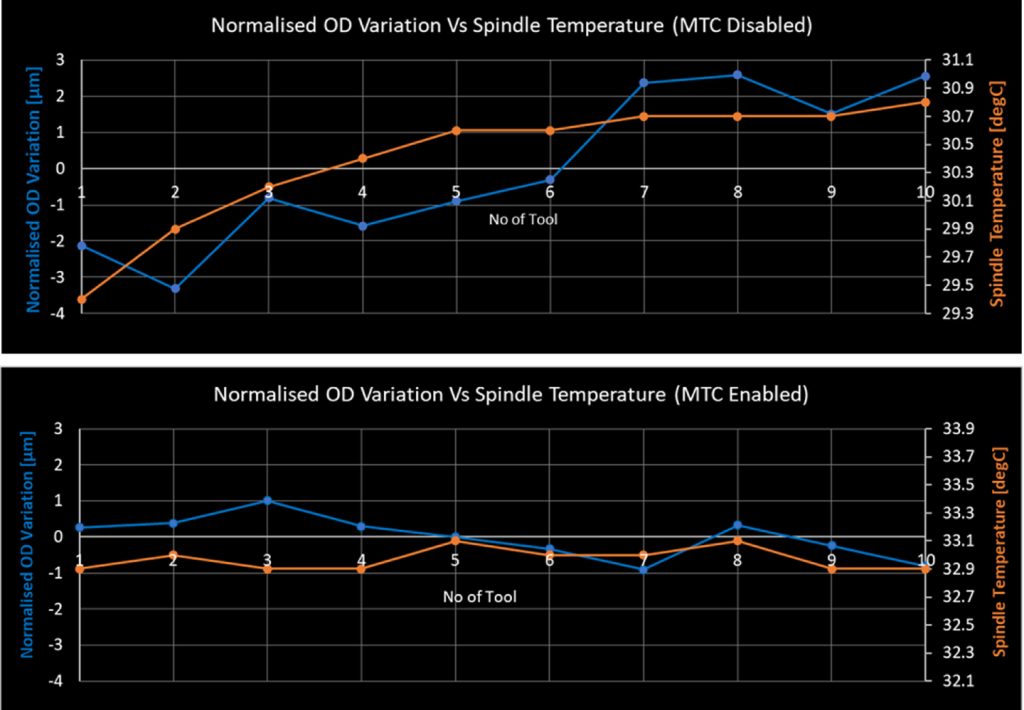

“We have introduced something that we have been awarded a patent for in the US and have patents pending around the rest of the world that we call, ‘Motor Temperature Control.’ We use the motor drive to not only control torque and velocity, but also the temperature by playing with the efficiency of the motor. In doing so, we can hold the motor at a constant temperature, which – in a precision-machine tool in particular – can eliminate the largest source of error, which is thermal variation of the spindle causing dimensional error. Holding the spindle at a constant temperature makes a dramatic improvement in the accuracy of the final machine,” explains Boland.

Another unique technology that ANCA has developed automatically detects the subdivisional error in the encoders or linear scales, and compensates for it, improving the accuracy of these feedback devices.

“We also have developed a technology that we call ‘iBalance,’ where they use the error signal from the servo drives to determine the out-of-balance of the spindle. iBalance then either guides the operator to balance the spindle, or it uses software that learns the out of balance and compensates for that to eliminate the cyclical error that occurs from that out-of-balance” says Boland.

ANCA’s technological innovations have contributed significantly to the high-precision tool-cutting industry. Boland and his team are proud of their many achievements, and they continue to contribute to the industry. Boland says that there are continuous developments occurring in technology, and points to the contribution they have made over the years to motor and drive technology and machine and machine tool technology.

With global tradeshows and events such as GrindingHub in Stuttgart, Germany and IMTS in Chicago, Illinois early September of this year, Boland reserves making any specific product or technology announcements. But he does give some hints to what to watch out for.

“We are looking for performance and reliability as the main drivers of our R&D. Accuracy, productivity, and cost are the dimensions we are working on. At GrindingHub, we released what we have been working on in terms of productivity in the machines involved with self-optimization. We are also working very hard on factory-level automation, producing cutting tools in a very efficient fashion, and will be releasing significant software in that space,” says Boland.

When Boland and McCluskey started ANCA 50 years ago, they started with one “mini” computer that was about as tall as they were. The speed of advancing technology has been astonishing to many of us, and Boland reflects on the change of technology that he has witnessed. Moore’s law, or the observation that the number of transistors in an integrated chip doubles roughly every two years and the cost to make them simultaneously halves, has been the enabler for advancing their CNC technology.

Boland says, “Our early years were limited by the performance of the computers at the time, limited by the memory of the computer chips. You spend your life optimizing code to try and save a few bytes of data storage because that was a limiting factor. Then with Moore’s law, the increase in the performance of computers in density and cost allowed us to realize some of what we had in our dreams in the early stages. The fact that we can handle such incredible volumes of data and make sense out of it. Each servo drive has far more intelligence than the entire system did 50 years ago.”

ANCA has grown significantly over the years and will continue to bring a wealth of experience and industry expertise guided by the vision of the company’s founders, Pat Boland and Pat McCluskey.

More Information

Related Story

ANCA’s FX7 ULTRA: Ultra Impressive and Ultra Precise. Innovation at its Finest

ANCA is a world-leading designer and manufacturer of high-quality innovative products and solutions. Specializing in the niche market of CNC grinding machines, motion controls and manufacturing solutions, their products make the tools and components that contribute to essentially everything used in the modern world. Russell Riddiford, President of ANCA Americas, discusses ANCA’s world-class tool grinders and cutters, including their latest FX7 ULTRA, and their growing presence in Canada.