ABB’s Condition Monitoring Services Ensure Safety and Reliability of Cement Plant in Canada

May 19, 2021

With the help of ABB Ability Condition Monitoring services, the Ash Grove cement plant in Mississauga was able to maximize its operational uptime through predictive maintenance and continuous monitoring of drives.

Ash Grove Cement, a CRH Company, is a major company in the cement industry, known for its commitment to safety, quality, and reliability. For over 137 years, Ash Grove has provided portland and masonry cements to construct the highways and bridges, commercial and industrial complexes, and single-and multi-family homes core to the economic vitality and quality of life in the communities it serves. In 2019, Ash Grove shipped over 14 million tons of cement from its plants and network of terminals located across the United States and Canada, making it one of the largest cement producers in North America.

Predictive maintenance enhances safety and efficiency

The rise of the IoT has created a surge of new interest in machine condition monitoring solutions, and several companies around the world are already using it for optimized equipment monitoring. ABB’s digital services provide a customizable approach that improves uptime, safety and productivity of critical process equipment.

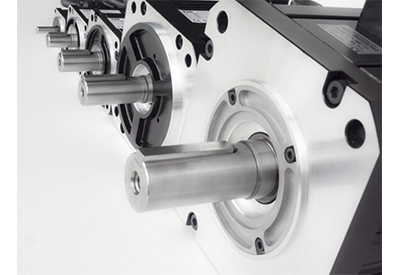

Variable speed drives are connected via gateway, with the ABB cloud. Using the ABB Ability™ Condition Monitoring the customer has access to the monitoring portal where all the service data is collected. Accessing live data the drive performance can monitored including availability, condition, operating parameters and fault events. As a result, maintenance can be planned according to actual needs rather than based on fixed schedules or unexpected breakdowns. It also offers the possibility of taking proactive decision built on real-time information on drive events.

The digital solutions also allow the plant operators to monitor equipment remotely and keep their employees safe. For example, ABB Ability™ Condition Monitoring services enable easy access to data from equipment in locations that may be difficult or dangerous to reach. Digital monitoring makes it possible to automate maintenance planning, inspection, diagnostics of the equipment.

Ash Grove’s Mississauga plant opted for ABB’s Ability Condition Monitoring for Drives (CMD) services, due to the criticality of the monitored drives and believed that the predictive features combined with the bi-annual expert reports would allow them to achieve efficient and appropriate maintenance planning. They deployed CMD for three ACS1000 medium voltage drives and two ACS800 drives.

“As an organization, the Ash Grove Mississauga cement plant is moving towards predictive maintenance and condition-based monitoring to improve the overall plant reliability. We think that the remote condition monitoring tool for our ABB drives will provide us with all the required data and statistics, based on which we can develop our maintenance strategy,” said Tian Huang, Electrical Manager at Ash Grove Mississauga.

ABB Ability CMD has replaced the obsolete drive monitoring system of the cement plant and now plays a critical role in ensuring continuity and reliability of plant operations. After six months of subscription, the plant is planning now to extend and expand the usage of ABB Ability digital services to more assets.