A Quick Summary of OSHA’s NEP Update and What This Means for Manufacturers

March 16, 2020

If you’re involved in meat and poultry processing, plastics and steel manufacturing, or another industry that has a high rate of accidents resulting in amputations, then you’re likely aware that the Occupational Safety and Health Administration (OSHA) is stepping up National Emphasis Program (NEP).

The NEP is a temporary program that zeroes in on high-hazard industries to ensure that individual facilities have the right machine guarding and other safety elements in place to minimize the likelihood of a serious accident. Visits from OSHA inspectors occur without warning, so manufacturers need to be prepared.

Which industries will be targeted?

OSHA will be looking at facilities belonging to the 75 North American Industry Classification System (NAICS) codes with the greatest number of amputations. These industries all have in common the fact that they make use of heavy machinery that includes pinch points, cutting edges and other likely sources of hazardous motion.

Since the organization’s enforcement history shows a direct link between injury rate and the degree to which equipment has not been properly guarded or maintained, the inspectors will be specifically looking for any instances of improper machine guarding.

How should companies prepare?

Since the NEP is a secret program that doesn’t announce inspector visits ahead of time, manufacturers need to do as much as possible to ensure that all their machinery is safeguarded before the program begins. (Of course, it goes without saying that companies should do this primarily for the safety of their employees, not just to avoid OSHA violations.)

For manufacturers that are unsure of how to best implement the necessary safeguarding, a risk assessment is a good way to start. Omron’s safety specialists perform hundreds of risk assessments every year to help companies reduce risk and protect their teams. This service is the first step in identifying and prioritizing equipment that presents the greatest hazards.

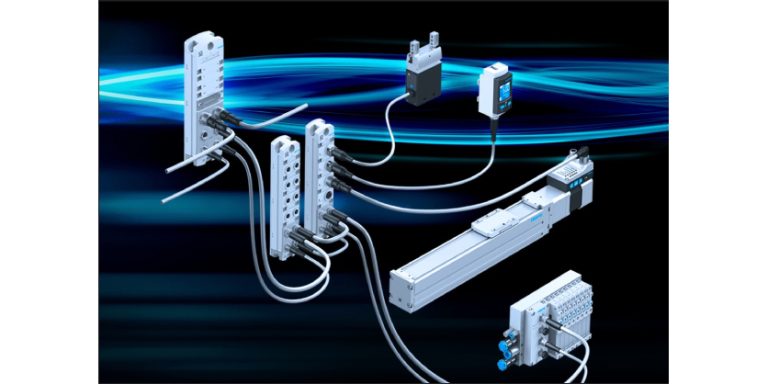

Once a risk assessment has been completed, companies can implement safety-related technologies to prevent employees from accessing hazardous parts of machinery or halts the machinery before employees reach the danger zone. Omron’s F3SG-SR safety light curtain, for example, senses when someone has entered a hazardous area and signals the machine to stop.