3 Ways to Protect a VFD Braking Resistor from Short-Circuit Failure

April 13, 2020

By Ryan Doxsey

Energy overload situations can cause braking resistor failure, but is easily prevented with the right equipment and system design. In this article we’ll explain the cause of overload conditions and present three methods that will help you address this common problem. After all, you want to protect your VFD and related equipment in order to prevent unhappy customers and co-workers that experience a system failure.

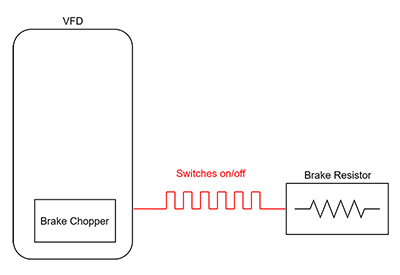

Brake Resistor – Normal Operation

Under normal operation, the brake resistor is driven by a brake chopper transistor when excess energy is returned to the VFD. The brake chopper continuously turns the brake resistor on and off until the extra energy is dissipated. The resistors are sized to be used with a brake chopper and not for direct, continuous connection to the VFD’s DC bus.

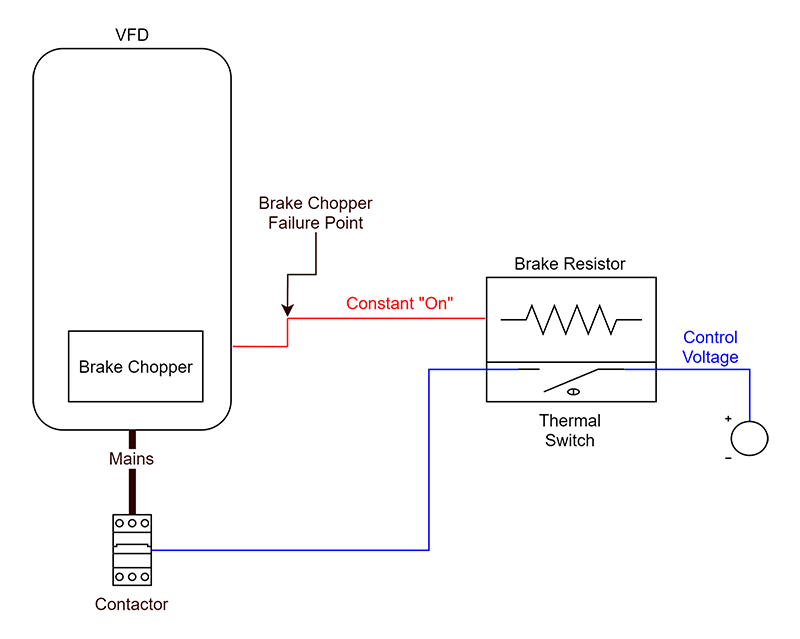

What is Brake Chopper Failure?

If a brake chopper fails, it most likely fails in a “shorted” state. During a short-circuit failure, the brake resistor is subsequently connected, unrestricted, to the DC bus voltage of the VFD. As mentioned earlier, the brake resistor is sized to be used with a chopper circuit. Consequently, a direct connection to the DC bus overloads the brake resistor and can cause external damage and also become a fire hazard.

3 Ways to Safeguard a Brake-Resistor from an Overload

There are several options to prevent a braking resistor failure from an overload situation. KEB suggests at least one of these options:

- Brake-Chopper Transistor Monitoring Board

- Installation of Brake Resistors with a Thermal Switch

- Intrinsically-Safe Brake Resistors

1. Brake-Chopper Transistor Monitoring Board

KEB offers an optional monitoring board for various sizes of F5 VFDs. This board monitors for short-circuit failures within the brake chopper circuit. When a brake chopper malfunction is detected, a drive fault is generated that triggers a dedicated form C relay. The control system should be designed in such a way that power is removed from the drive or resistor when this relay is opened.

2. Brake Resistors with a Thermal Switch

Brake resistors can be equipped with a thermal switch to detect a potential overload condition. When a resistor is overloaded, it attempts to dissipate more heat than it was designed to do. In this case, the thermal switch will open when the temperature of the resistor becomes too hot. KEB recommends interrupting one of the high voltage supplies to either the VFD or the resistor. Refer to the next 2 diagrams on how this can be implemented.

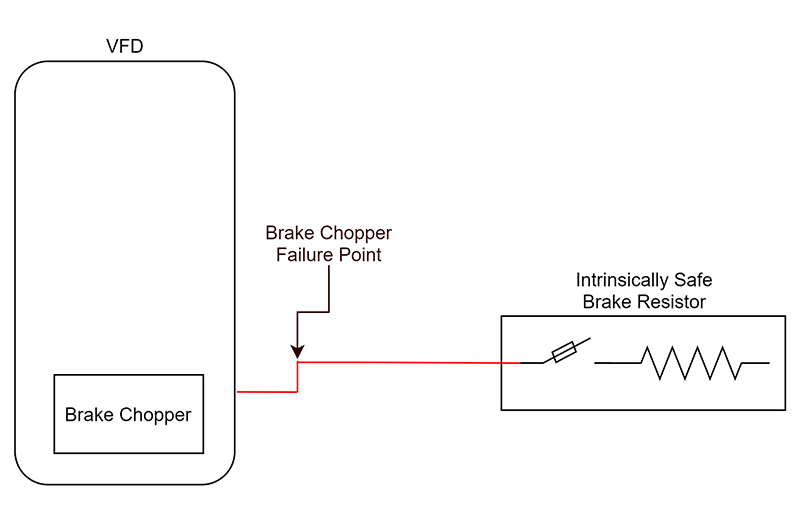

3. Intrinsically-Safe Braking Resistors

KEB also offers braking resistors that are intrinsically safe. These resistors come equipped with an internal overload protection that will open, similar to a fuse, when overloaded. This option does not require any additional hardware or control devices as the protection is built-in to the resistor.