Supporting Customers in Unprecedented Times

May 5, 2020

For the ABB Drives field service team, the circumstance of social distancing presented a unique challenge to “business as usual”. How do you commission or trouble shoot medium and low voltage drives if you can’t be near them?

The answer, it turns out, was simple. Use the tools you have – laptops that fully support ABB Tools to condition and work on drives, supplemented by remote tools that allow customers to interact with service team in office, to go through the work with ABB’s customers.

The hardest part was determining what work at which customers could be done remotely.

“We started with, and continue to add, to a list of what can be handled remotely,” explains Yasser Bahaa, Service Manager, MV Drives. “Each situation has to be examined, not just the work to be done.”

The main questions to be considered are:

- – What is the criticality of work to be done on-site?

- – Can it be supported remotely?

- – Is customer willing to help support a remote success?

- – Does the customer have the right personnel on-site to complete the work?

- – Does the customer have the right tools to complete the work?

The last three questions are just as important as the main one – Can it be supported remotely? For the Drives Service team to offer remote services, including commissioning, the customer must have an electrically competent, qualified person on site that understands drives terminology, has lock out/tag out authorization, and is comfortable working on drives.

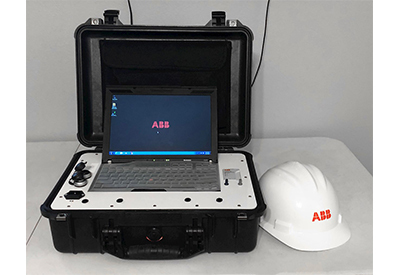

It is also critical that the customer have the necessary tools to complete the work with the remote service team, including internet connection for the drive and communication options, and the capability to video chat using tools such as Microsoft Teams, Skype or even FaceTime. If all of these criteria has been met, and the team feels the work can be completely remotely, an ABB laptop with all the needed monitoring and setup tools is sent to the customer and a remote meeting is scheduled.

Remote support means that customers facing the same restrictions can continue operations without letting additional people on site. Other safety protocols, such as job site assessments, are still conducted by the entire team, just not in the same location.

“Our commitment to safety – both by not being there and by continuing to do perform routine safety practices – has been appreciated by our customers,” states Neil Kenney, Operations Manager, Drives Field Support.

The Drives Services team is demonstrating ABB’s commitment to serving their customers by keeping them safe and productive in this unprecedented time.