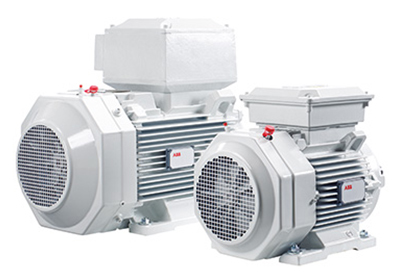

High Power Density Motors Create New Opportunities for Machine Builders

April 1, 2022

ABB has upgraded its extensive range of High Dynamic Performance (HDP) induction motors. This creates new opportunities for machine-building OEMs seeking motor and drive solutions with excellent dynamic response and high power density. The motors are typically used in plastic and rubber extrusion, injection molding, winders, lifting, conveyors, test benches and machine tools.

The upgraded HDP motor range enables ABB to offer machine builders frame sizes between 80 and 400, and output capacities up to 2 megawatts (MW) – as well as alternative variants such as high-speed and water-cooled motors. The motors are designed for use with a VSD and ABB can provide matching motor and VSD packages across the frame-size range.

“ABB is well known for its optimized motor and VSD packages that provide precise motor control and maneuvering capabilities in a wide variety of general industrial applications,” said Marcus Westerlund, Product Manager, Special Motors at ABB. “The HDP motors now bring the same advantages to machine builders who need the extra boost in power provided by a high-torque design and exceptional power density.”

High power density benefits both retrofits and new build machinery

Machine builders can capitalize on the high power density of HDP motors in two ways. They can retrofit an existing machine with a more powerful replacement motor to boost performance; or they could select a more compact, yet equally powerful motor when designing a new machine to reduce its footprint.

Low inertia and high overload capacity

HDP motors are designed to enable fast motion control and high maneuvering precision due to their low inertia and high overload capacity. Low-inertia motors are ideal for applications requiring fast changes in rotational direction to enable, for example, faster back-and-forth machine motion.

Easy installation

ABB has prioritized ease of installation as an integral element of the HDP design. That makes it easy to install a replacement HDP motor into an existing machine without excessive engineering work. Furthermore, ABB has considered simplicity in everything from accessible connection points to installation of accessories, such as cooling fans, encoders and brakes, whether from ABB or a third party.

Customization

The upgraded HDP motor range includes all the commonly-requested frame sizes and technology variants such as water-cooled, high-speed and megawatt-class alternatives to allow ABB to meet most machine-building requirements without extended delivery times. Should the standard design not meet a machine builder’s specific needs then it can be customized.

HDP motors are compliant with the IEC 60034 standard and suitable for unrestricted global use. Worldwide technical support is provided to OEMs and end users through ABB’s global services organization.