FjordAL Aluminium builds its first plant with top-of-the-line technology from Schneider Electric

November 15, 2019

Quebec-based manufacturer FjordAL Aluminium is officially starting production in its inaugural plant at the end of November. The plant is one of the first to be fully built with the Schneider Electric EcoStruxureTM system in mind, aiming to open its doors as a safe, efficient, sustainable and reliable facility from the get-go.

EcoStruxureTM is Schneider Electric’s IoT-enabled, plug-and-play, open, interoperable architecture and platform offering innovation at every level, from Connected Products and Edge Control to Apps, Analytics and Services. The platform connects everything in an enterprise from the ground floor to the top floor, collecting and analyzing critical data to discover meaningful insights.

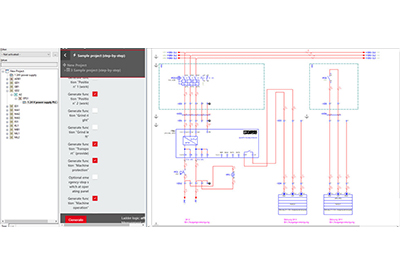

In addition to leveraging EcoStruxureTM, the plant is one of the first to integrate Schneider Electric’s new EcoStruxureTM Hybrid DCS and Citect Anywhere software, which allows businesses to run full manufacturing capabilities remotely, with the click of a button. Hybrid DCS is a single automation system used to engineer, operate and maintain an entire plant in a single common database. Citect Anywhere helps with accessing data from a tablet or mobile phone.

The database enables active services to share information across all the components of the automation system, as well as share real-time engineering data with all the users, making maintenance easier. The system enables users to achieve operational profitability from design engineering to meeting the demands of modern-day production. Hybrid DCS is proven to deliver tangible value to any company’s bottom line, including a 100% increase in ROI in less than three months and up to a 30% reduction in process energy cost.

“We’re so excited that FjordAL Aluminium is leveraging the power of Hybrid DCS from the minute their plant doors open, guaranteeing that they will see results early on,” said Michael Painchaud, Industry Sales Representative at Schneider Electric. “Building an entire plant using the full suite of Schneider Electric products was a team effort, and we thank everyone involved to help get FjordAL Aluminium up and running efficiently.”

Adding to the features of Hybrid DCS is the embedded simulation capabilities that allow plant managers to simulate the entire system at any time, which greatly reduces errors during the design phase. This reduces time to market, engineering costs and increase the quality of the final control system.

“We are looking forward to running our manufacturing through the EcoStruxureTM system in order to efficiently and effectively manage our production,” said Maxime Harvey, co-owner at FjordAL Aluminium. “We chose to use Schneider Electric products because of the advanced technology that they offer, including the ability to manage everything in one place, which will ultimately make our lives easier while improving productivity and safety simultaneously.”

FjordAL Aluminium was founded in 2017 with the vision of becoming a first-class supplier of high quality aluminium redraw rod at a competitive price. They manufacture aluminium rods through continuous casting and rolling, and only use aluminium from the best source the market can offer.