Festo Honoured for Free App Showing Field Personnel How to Build, Maintain Covid-19 Equipment

August 28, 2020

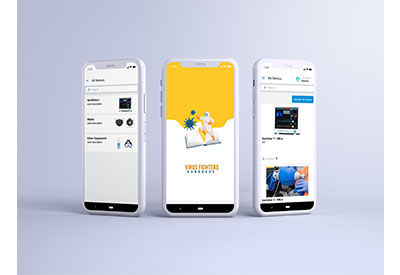

The Virus Fighters’ Handbook, a smartphone app co-developed by Festo and Germany’s Fraunhofer Institute for Manufacturing Engineering and Automation (IPA), provides a digital manual for field personnel on how to operate and maintain open source equipment, including ventilators, in the fight against Covid-19. Festo and the IPA were honoured at the recent Give a Breath Challenge awards for designing the app, which will be made available worldwide, for free, for iOS and Android devices and as a web application.

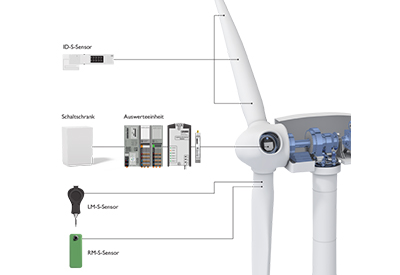

The app is based on Festo’s Smartenance remote maintenance app, adjusted with input from medical experts from several hospitals, and intended primarily to benefit irregular staff recruited to work in field hospitals and who are unfamiliar with the equipment. Registered users receive detailed information from medical professionals and service professionals via the app about how to build, operate and maintain the equipment.

In Smartenance, one of the company’s powerful new digital tools, Festo was able to provide a stable platform that needed only minimal reprogramming. The Smartenance software is normally used for the maintenance and servicing of machines and systems in industrial production. The IPA team, which specializes in the development of didactic material in the field of medical technology, provided the training content.

“Being able to help people around the world fight corona with a purely digital product has given the development team a special boost,” says Andreas Oroszi, Head of Digital Business at Festo. “Festo is proud that their idea has now been awarded a prize.”

Munich Re and the Fraunhofer Gesellschaft launched the Give a Breath Challenge in March. The challenge was split into three categories. The first category sought designs for non-invasive lung ventilators and oxygen concentrators, the second for the development of non-invasive respirator masks, and the third for the provision of information on the use of the equipment along with basic knowledge on Covid-19. With these three components, a complete respirator system can be set up by almost anyone. It had to be possible to produce the equipment anywhere in the world using 3D printing or other fast manufacturing processes. The primary aim was to create the technological basis for the rapid local supply of ventilators to cope with imminent shortages in the local emergency treatment of Covid-19 patients and mitigate the impact of the pandemic for people affected worldwide.

Over 150 project designs from all over the world were submitted to the Challenge.